Diaphragm capable of measuring pressure distribution in pole group and preparation method of diaphragm

An internal pressure and diaphragm technology, applied in the direction of measuring force, measuring device, battery pack components, etc., can solve the problems of uneven local stress, cell failure, affecting the performance of the battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

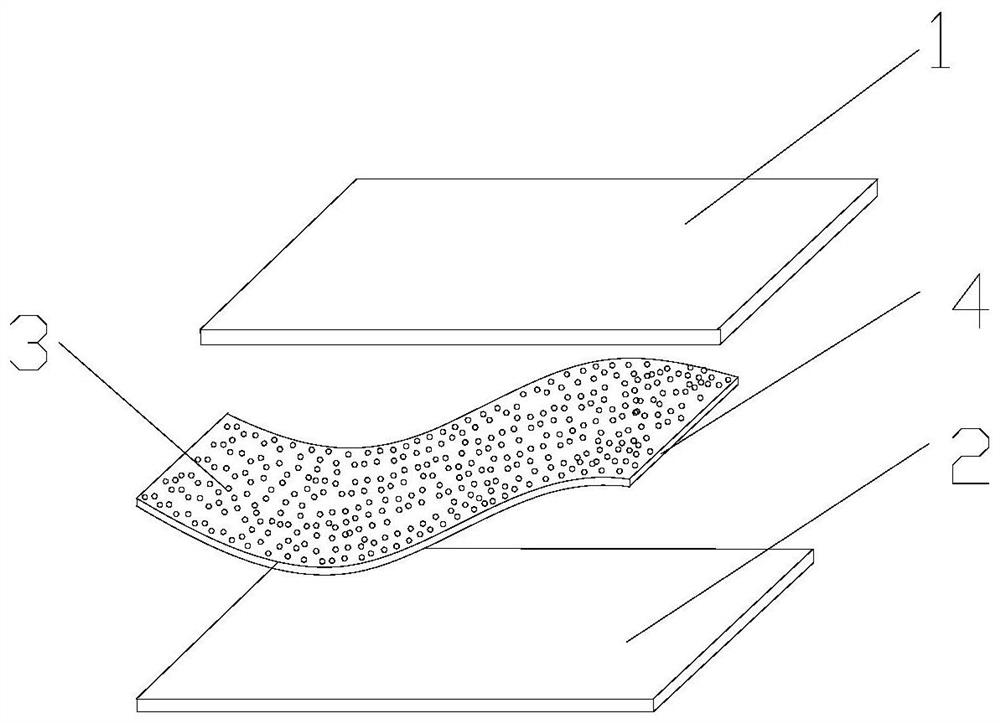

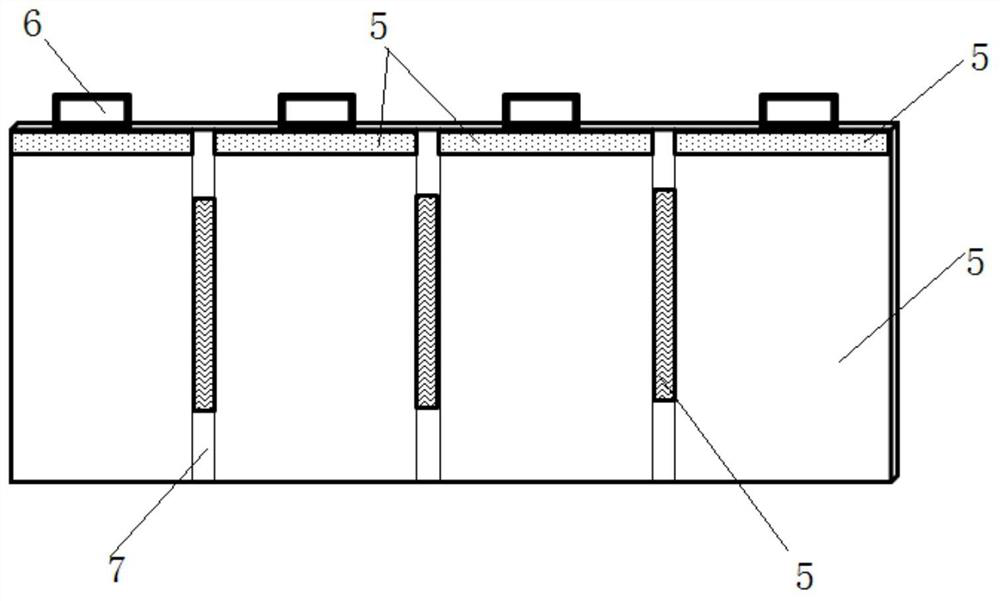

[0031] Referring to the drawings for details, this embodiment provides a diaphragm capable of measuring the pressure distribution in the pole group, including a diaphragm body, which includes upper and lower base films 1, 2 and color-developing capsules 3, the upper and lower layers An adhesive layer 4 mixed with color-developing capsules is arranged between the base films to form a pressure-sensitive diaphragm structure. Basement membrane pores are respectively arranged on the planes of the upper and lower basement membranes, and the diameter of the basement membrane pores is smaller than the diameter of the color-developing capsule. The pore diameters of the basement membranes of the upper and lower basement membranes and the diameters of the color-developing capsules are in the nanoscale. The upper and lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com