Motorcycle brake anti-lock braking system durability test bench

A technology for brake anti-lock braking and testing experiments, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc. It can solve the problems of consuming a lot of manpower and material resources, and the durability testing equipment is in a blank state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

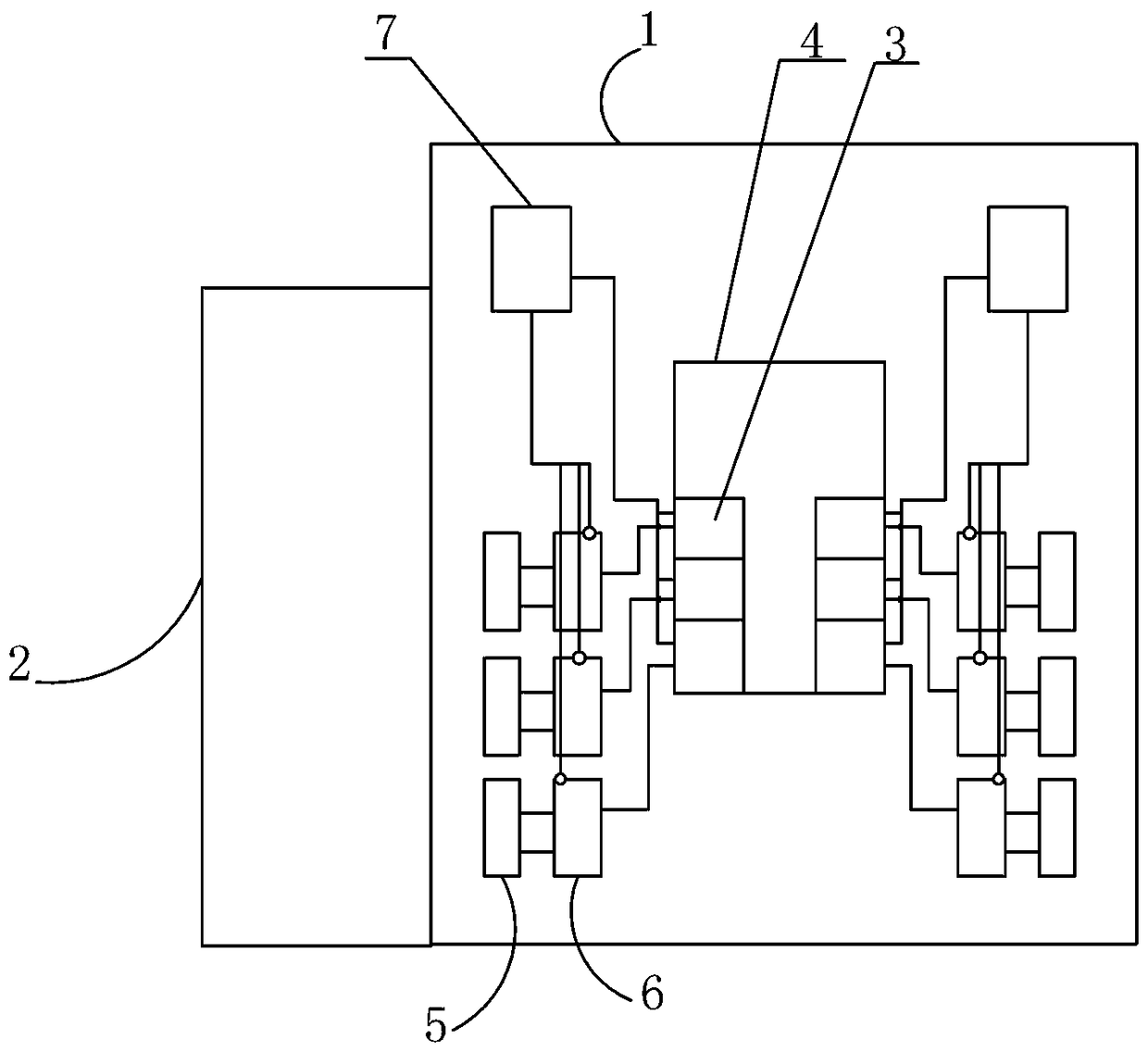

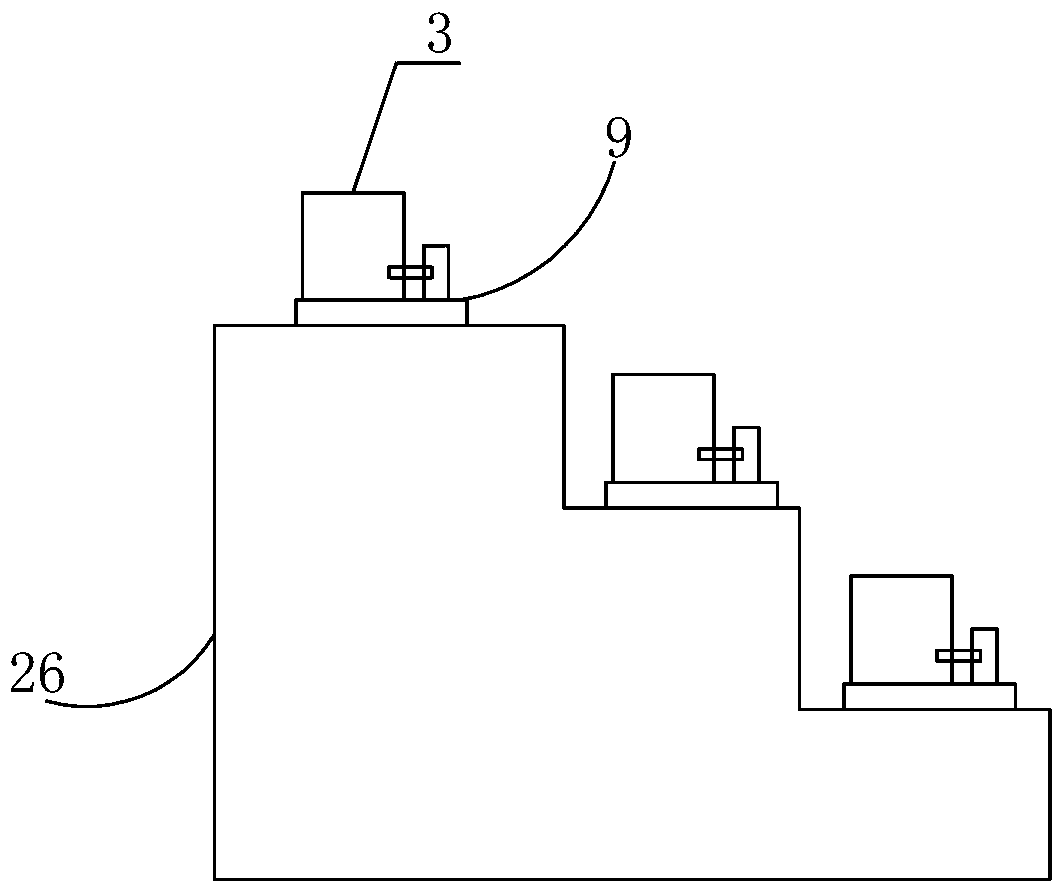

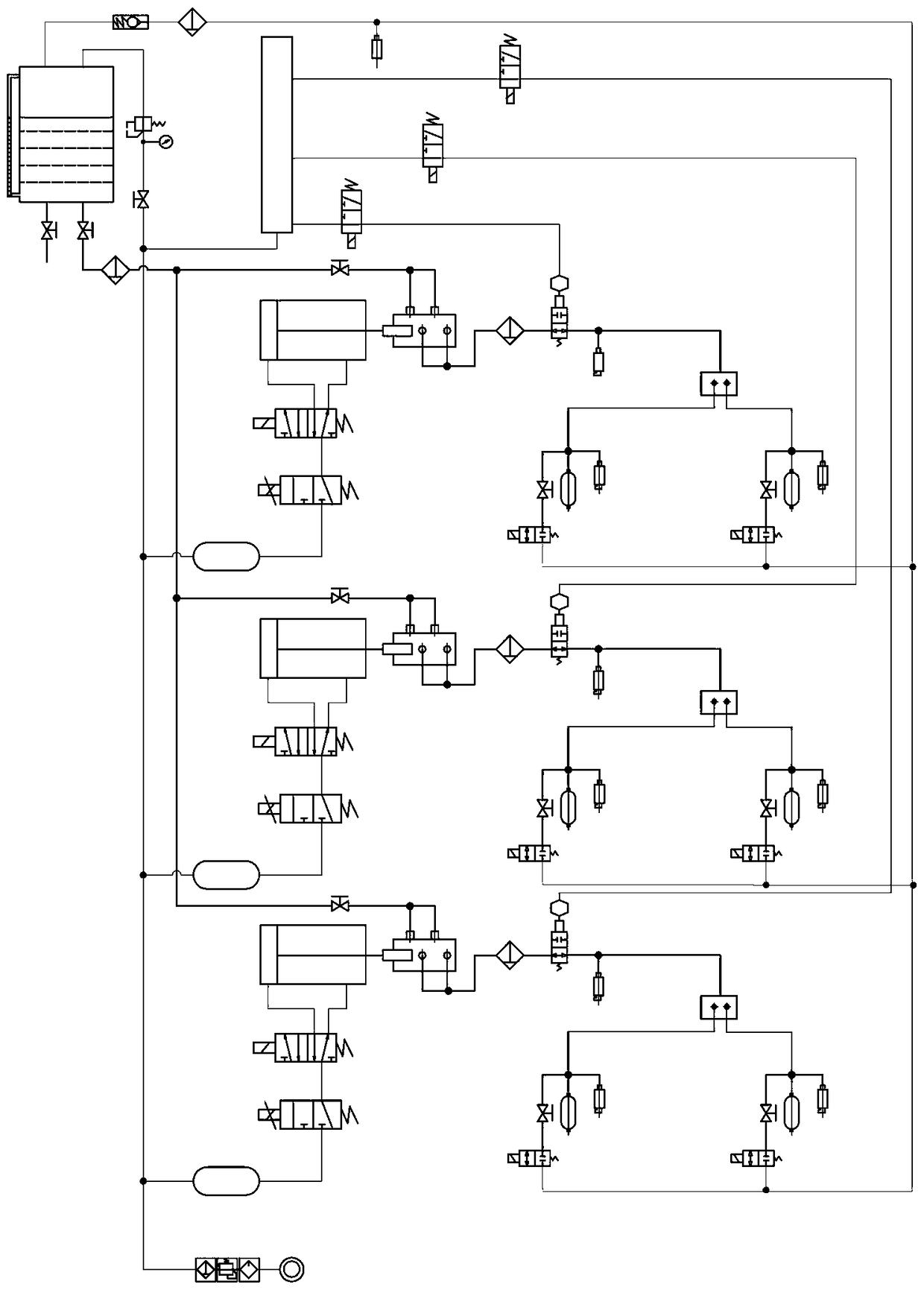

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 shown;

[0026] The motorcycle anti-lock brake system durability test bench of the present invention comprises a test bench 1, an electric control cabinet 2 and a hydraulic loading device, and the test bench 1 is provided with multiple groups of motorcycle anti-lock brakes Dead system durability test device, each group of motorcycle brake anti-lock brake system durability test device includes a braking force loading mechanism 5, a motorcycle simulation master cylinder 6, at least one group of motorcycle simulation wheel cylinders 8, and a test bench 1 on the fixed fixture 9 for the anti-lock brake system 3 of the motorcycle to be tested; the braking force output end of the braking force loading mechanism 5 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com