Washing process

A technology of process and washing medium, which is applied in the field of washing process, and can solve the problems of unobserved, damaged catalyst component particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0257] Preparation of ZN Catalysts by Emulsion Solidification

[0258] raw material

[0259] TiCl 4 (CAS 7550-45-90) was supplied by a commercial source.

[0260] 20% butyl ethyl magnesium (Mg(Bu)(Et)) in toluene supplied by Crompton

[0261] 2-Ethylhexanol supplied by Merck Chemicals

[0262] 3-Butoxy-2-propanol supplied by Sigma-Aldrich

[0263] Bis(2-ethylhexyl) citrate by Contract Chemicals

[0264] 1-254 by Evonik

[0265] Heptane, supplied by Chevron

[0266] Preparation of Mg complex

[0267] 3.4 liters of 2-ethylhexanol and 810 ml of propylene glycol butyl monoether (4 / 1 molar ratio) were added to the 20 l reactor. Then, 7.8 liters of a 20% solution of BEM (butylethylmagnesium) in toluene supplied by Crompton GmbH were slowly added to the well stirred alcohol mixture. During the addition, the temperature was kept at 10°C. After the addition, the temperature of the reaction mixture was raised to 60°C and mixing was continued at this temperature for 30 minute...

example 2

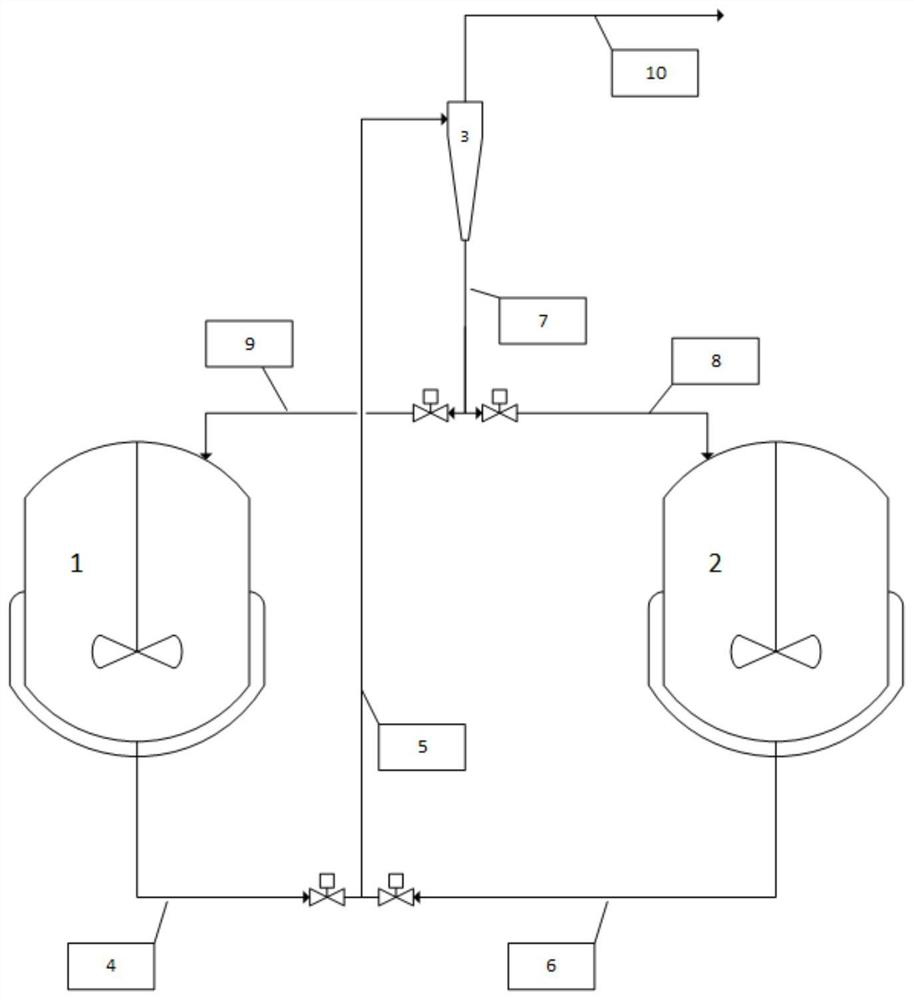

[0274] A hydrocyclone with a fractional particle size d50 of 13 μm was purchased from Krebs. Particles smaller than 13 μm enter the waste stream essentially from the top of the cyclone. Trials were carried out using a hydrocyclone connected to the catalyst preparation reactor unit 1 by connecting lines 4 and 5 . The catalyst was prepared according to the procedure described in Example 1.

[0275] The separation in the hydrocyclone is completed in less than 25 minutes.

[0276] refer to figure 1 , in hydrocyclone unit 3, the solid catalyst particles and liquid medium are separated by transferring the mixture from reactor 1 through a hydrocyclone. The bottoms stream was removed from the hydrocyclone and transferred to Reactor 2. The pressure difference between inlet and top was 0.7 bar.

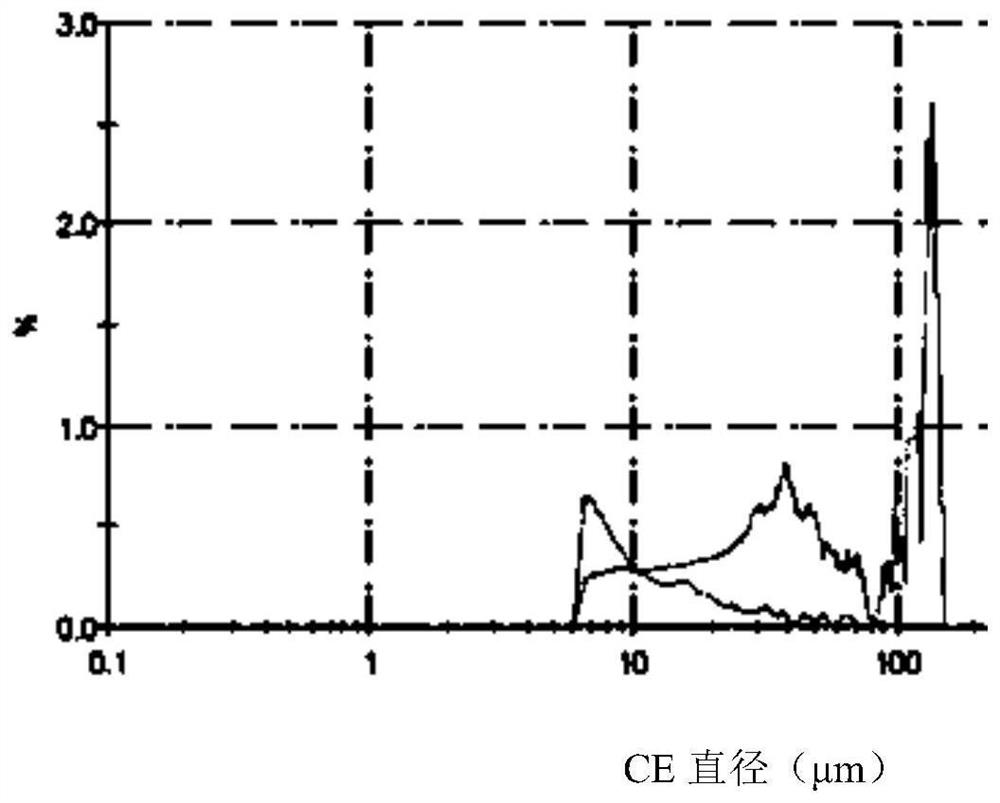

[0277] When analyzed using a Malvern particle size analyzer, the sample showed a fractional particle size of about the desired 13 μm ( figure 2 ).

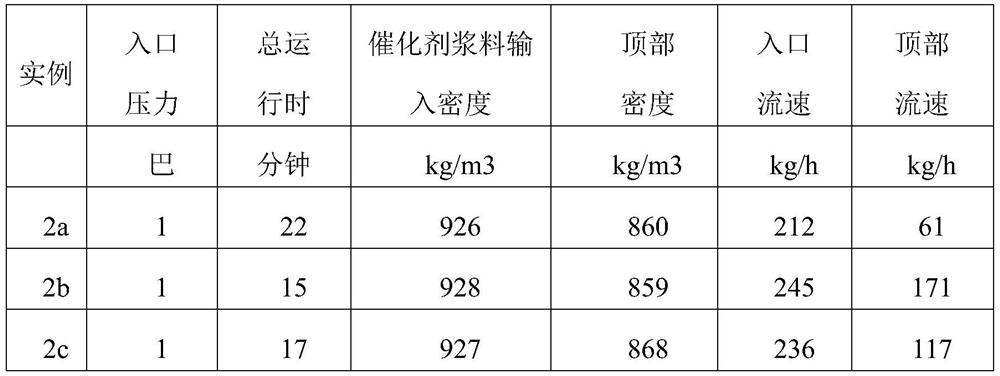

[0278]

[0279] Example 3 - Washi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com