Method for improving flavor of pea protein isolate

A technology of pea protein isolation and pea, applied in the protein composition of vegetable seeds, protein food ingredients, food science, etc., can solve the problems of affecting commodity value and destroying market labels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides the preparation process of the pea protein isolate with improved flavor:

[0046] (1) According to the ratio of material to water 1:3 (g:mL), soak the peas in deionized water for 10 hours at room temperature;

[0047] (2) adding deionized water to the soaked peas, the ratio of material to water is 1:3 (g:mL), and beating to obtain pea paste;

[0048] (3) Adjust the pH of the pea paste to 9.0 with 2.0 mol / L NaOH solution, stir for 1 hour, centrifuge at 3000 g for 15 minutes at room temperature to obtain the supernatant, and obtain pea paste;

[0049] (4) The pea milk is subjected to membrane separation treatment, the molecular weight cut-off of the membrane is 100kDa, the volume of the permeate is 2 times of the volume of the pea milk, the permeate is discarded, and the retentate is collected;

[0050] (5) Heat the retentate in a water bath at 90°C for 5 minutes, cool to 25°C, adjust the pH to 4.5 with 2.0mol / L HCl solution, centrifuge at 3000g ...

Embodiment 2

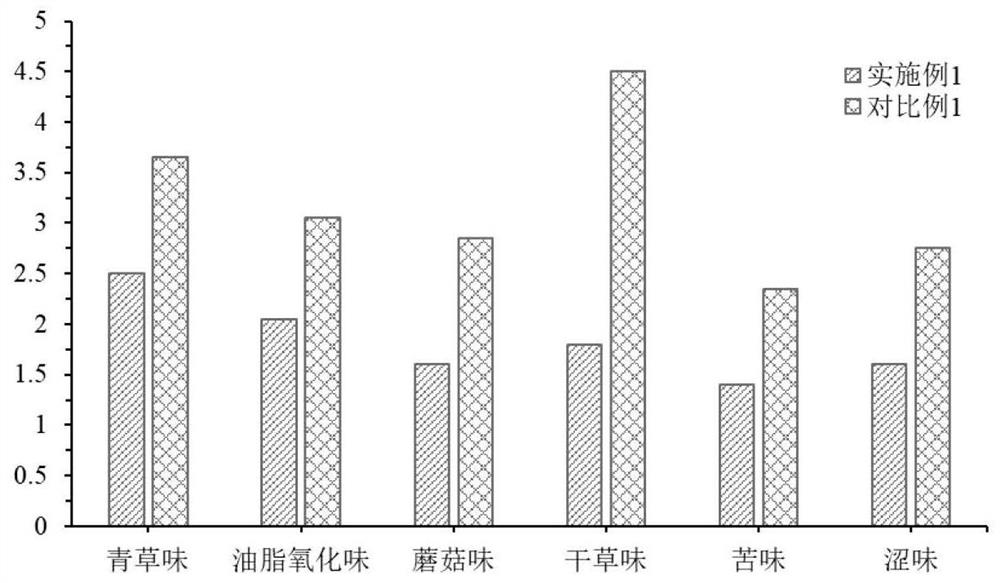

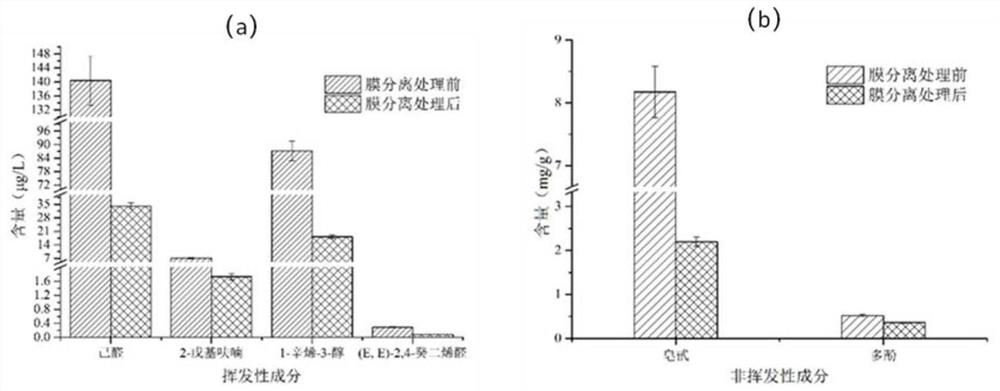

[0061] Effect of membrane separation treatment on the content of odor components in pea protein isolate:

[0062] (1) Soak 6kg of peas in deionized water according to the material-to-water ratio of 1:3 (g:mL) for 10 hours at room temperature;

[0063] (2) adding deionized water to the soaked peas, the ratio of material to water is 1:3 (g:mL), and beating to obtain pea paste;

[0064] (3) Adjust the pH of the pea paste to 9.0 with 2.0 mol / L NaOH solution, stir for 1 hour, centrifuge at 3000 g for 15 minutes at room temperature to obtain the supernatant, and obtain pea paste;

[0065] (4) The pea milk is equally divided into two parts, one of which is subjected to membrane separation treatment, the membrane molecular weight cut-off is 100kDa, the permeate volume is 2 times of the pea milk volume, the permeate is discarded, and the retentate is collected; in addition One part is not processed by membrane separation;

[0066] (5) Process conditions such as subsequent heating, ac...

Embodiment 3

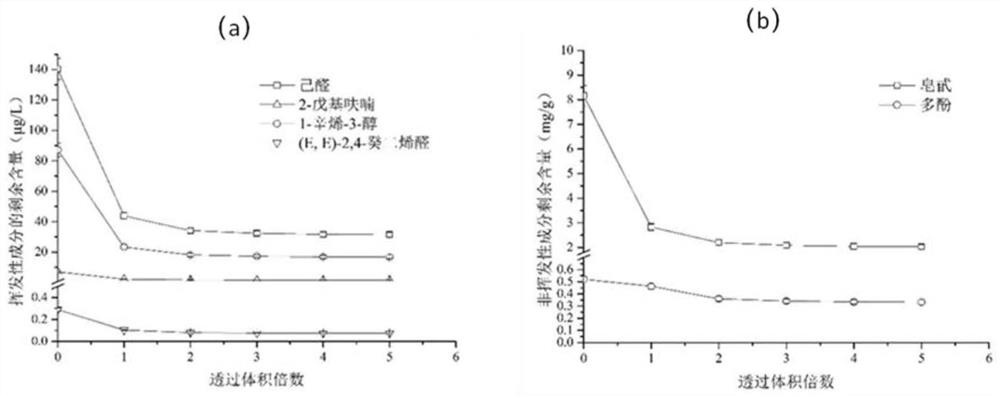

[0070] Effect of membrane separation permeation volume multiple on the content of odor components in pea protein isolate:

[0071] (1) Soak 15kg of peas in deionized water according to the material-to-water ratio of 1:3 (g:mL), and soak for 10 hours at room temperature;

[0072] (2) adding deionized water to the soaked peas, the ratio of material to water is 1:3 (g:mL), and beating to obtain pea paste;

[0073] (3) Adjust the pH of the pea paste to 9.0 with 2.0 mol / L NaOH solution, stir for 1 hour, centrifuge at 3000 g for 15 minutes at room temperature to obtain the supernatant, and obtain pea paste;

[0074] (4) Divide the equal amount of pea milk into five parts, and carry out membrane separation treatment. , to collect the retentate;

[0075] (5) Process conditions such as subsequent heating, acid precipitation, neutralization, sterilization and drying are the same as in Example 1.

[0076] The effect of membrane separation permeation volume multiple on the content of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap