Printing process for forming crack effect on surface of printed matter and printed matter thereof

A printed matter and crack technology, which is applied in the field of printing technology and printed matter, can solve the problems of poor color rendering process, poor expressiveness, and early adjustment of crackle effects, etc., and achieve the effect of strong three-dimensional effect and obvious expressive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

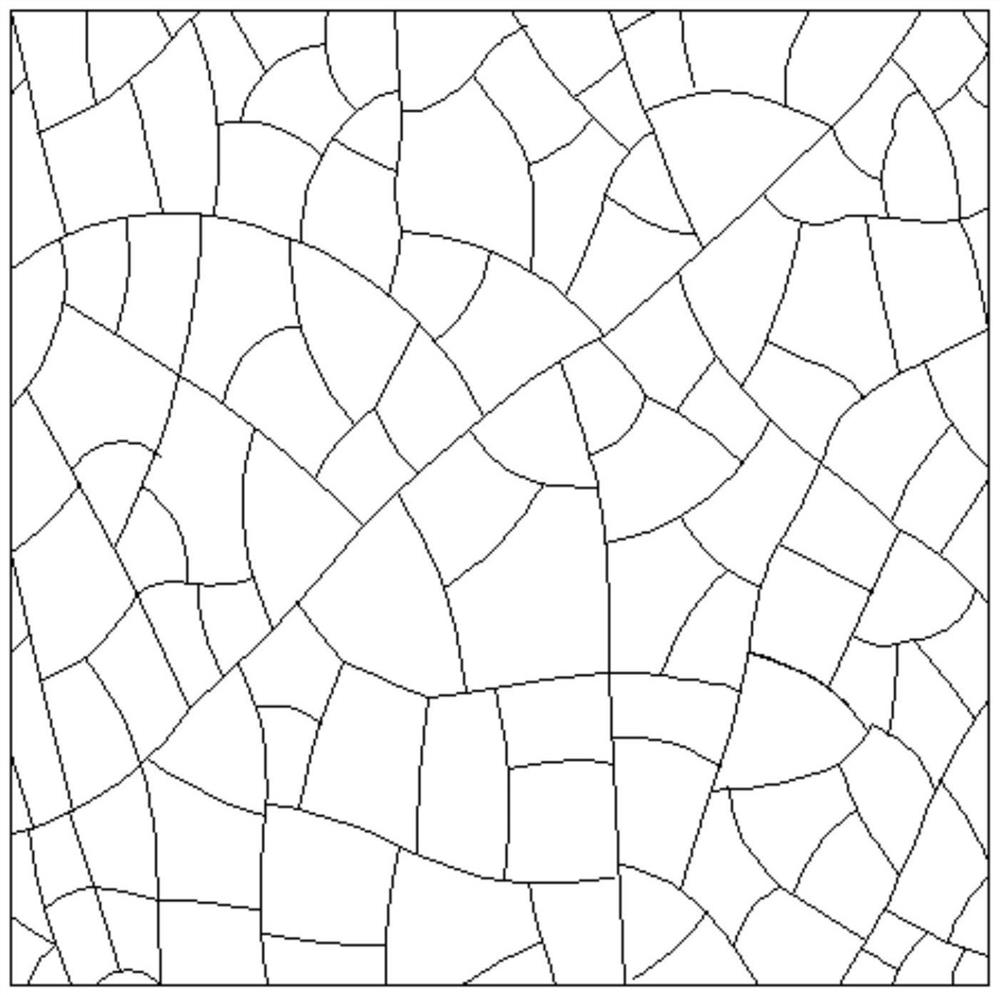

Image

Examples

Embodiment 1

[0043] A printing process for forming a crack effect on the surface of a printed matter, the process steps are as follows:

[0044] Step 1: Drawing confirmation: the drawing can be produced by the personnel of the printing factory, or the drawing can be provided by the customer. In any way, the drawing personnel need to modify it and confirm it to the customer. The confirmation content includes: confirmation of the color, the color number is provided by the customer; the content of the drawing confirmation; confirmation paper, quotation;

[0045] Step 2: Generation of printed molds:

[0046] S1: According to the crack effect to be formed, form a crack drawing, use the software Photoshop to adjust the crack details, and after the adjustment, confirm the texture, shadow area, etc., and convert it into a PDF file and import it, and then check it after printing. Late finished product reference;

[0047] S2: Paste the crack drawing on the template material of equal area, and cooper...

Embodiment 2

[0057] A printing process for forming a crack effect on the surface of a printed matter, the process steps are as follows:

[0058] Step 1: Drawing confirmation: the drawing can be produced by the personnel of the printing factory, or the drawing can be provided by the customer. In any way, the drawing personnel need to modify it and confirm it to the customer. The confirmation content includes: confirmation of the color, the color number is provided by the customer; the content of the drawing confirmation; confirmation paper, quotation;

[0059] Step 2: Generation of printed molds:

[0060] S1: Create a crack drawing according to the crack effect that needs to be formed, use the software Illustrator to adjust the crack details, and confirm the texture, shadow area, etc. after the adjustment, convert it into a PDF file, import it, and check it after printing. As a reference for later finished products;

[0061] S2: Paste the crack drawing on the template material of equal ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com