Foldable multi-section type pneumatic supporting leg and using method thereof

A linkage and cylinder technology, applied in vehicle maintenance, transportation and packaging, lifting vehicle accessories, etc., can solve problems such as the inability to ensure the safety of drivers and vehicles, inconvenience in getting on and off the vehicle, causing accidents, and slow lifting and lowering speed. Get off the car for work, solve the inconvenience of lifting, and increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

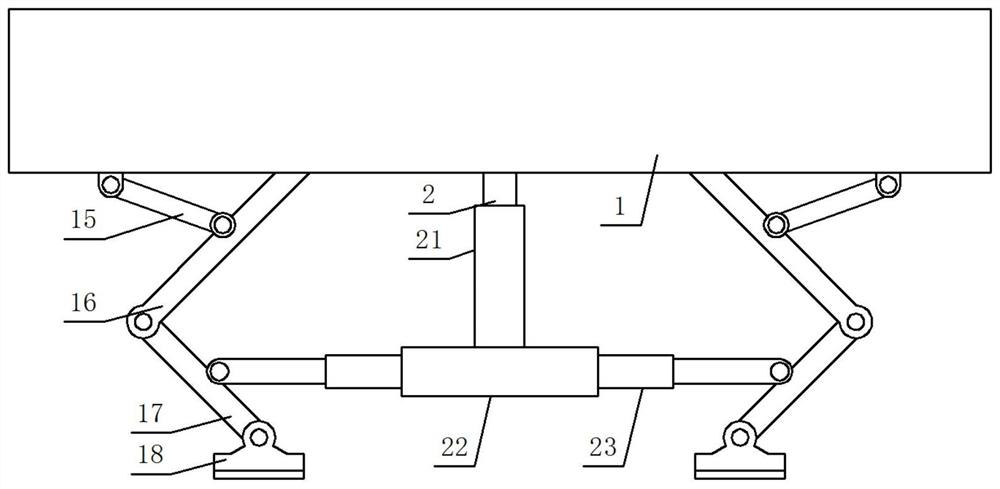

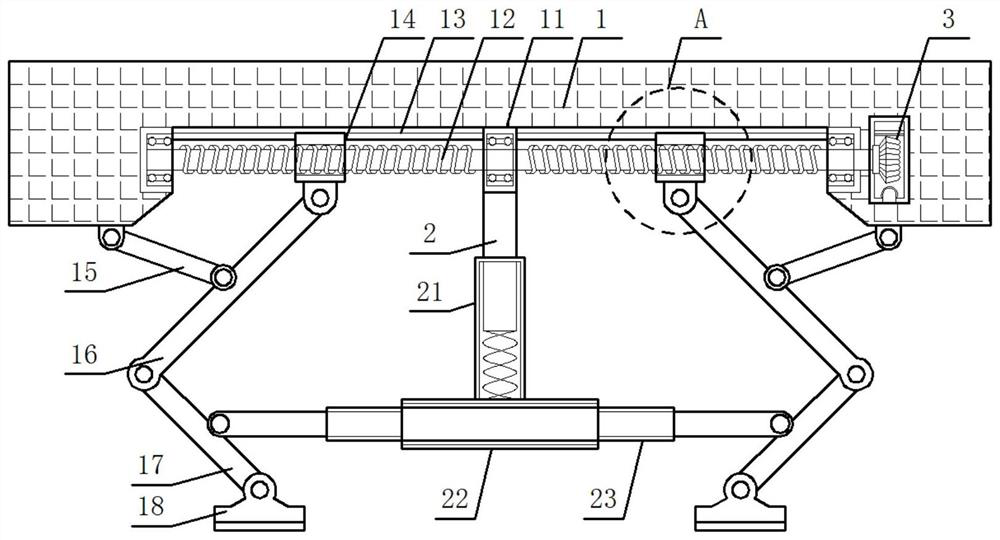

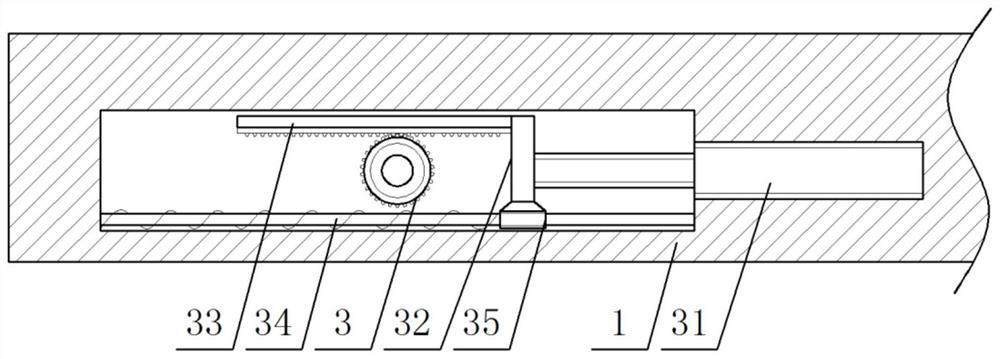

[0032] Embodiment 1: In order to solve the problem of inconvenient lifting of the outriggers of the semi-trailer, a foldable multi-section pneumatic outrigger is proposed in this embodiment, see Figure 1-4 , including a base plate 1, an engaging mechanism, and a link mechanism. The base plate 1 is a rectangular plate placed horizontally and horizontally. The top surface of the base plate 1 is fixed on the front end of the bottom surface of the semi-trailer. groove, the middle part of the rectangular groove is provided with a linkage bearing plate 11, a linkage bearing is installed in the linkage bearing plate 11, and a threaded long rod 12 penetrating horizontally is inserted in the linkage bearing, and the two sides of the rectangle groove Both ends are equipped with fixed bearings, and the two ends of the threaded long rod 12 are respectively inserted in the corresponding fixed bearings, and the threads on the two sections of the threaded long rod 12 are set in reverse symme...

Embodiment 2

[0036] Example 2: see Figure 5 , in this embodiment, the present invention also proposes a method of using a foldable multi-section pneumatic outrigger, comprising the following steps:

[0037] Step 1, start the uniaxial cylinder 31, control the air rod of the uniaxial cylinder 31 to extend slowly, drive the rack plate 33 to move forward slowly through the limit plate 32, and drive the limit cylinder 35 to slide along the limit rod 34, so that The limit spring is compressed and deformed, and the meshing drives the gear 3 and the long threaded rod 12 to rotate slowly. Since the threads on the two sections of the long threaded rod 12 are arranged in reverse symmetrical helical sleeves, the two threaded cylinders 14 are driven to form a reverse symmetrical horizontal direction. move;

[0038] Step 2, when the two threaded barrels 14 move oppositely and symmetrically, the T-shaped slide rail 13 is driven to slide along the T-shaped chute, and under the coordination of the hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com