Horizontal moving mechanism of three-dimensional movement photographic equipment support

A technology for photographic equipment and horizontal movement. It is applied in the direction of machine/stand, supporting machine, mechanical equipment, etc., which can solve the problems of inability to quickly reverse movement, cumbersome operation, and reduced shooting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

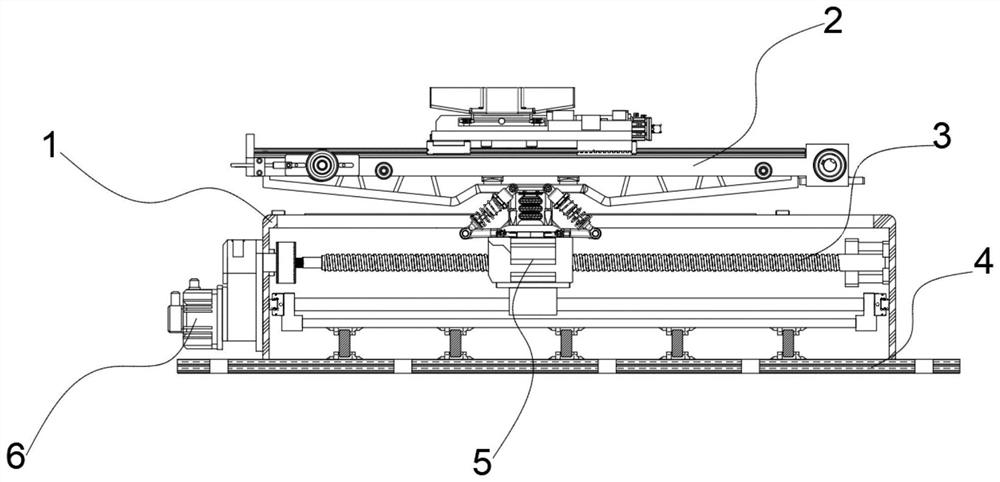

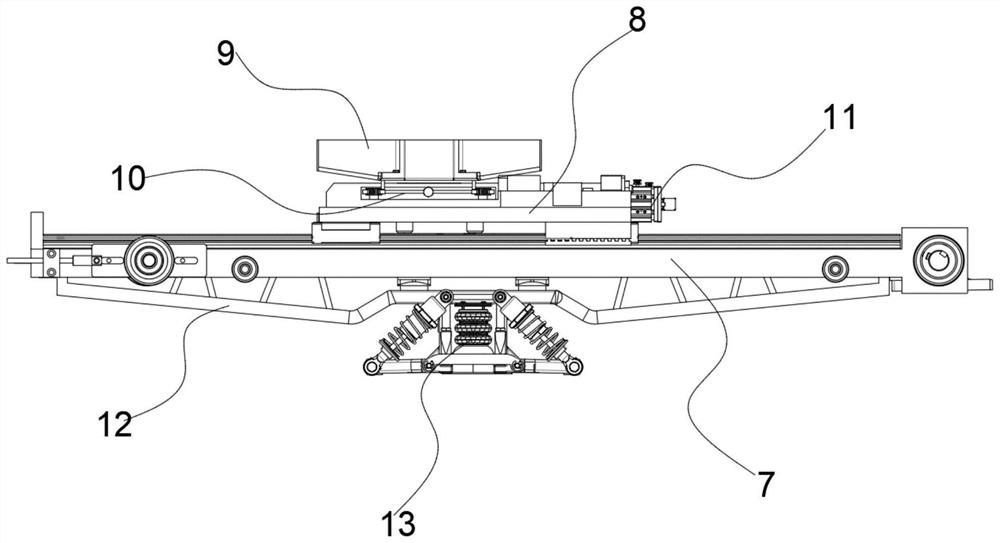

[0037] see figure 1 , in an embodiment of the present invention, a horizontal movement mechanism for a three-dimensional motion photography equipment bracket, which includes a protective housing 1, a secondary displacement assembly 2, and a threaded rod 3, wherein the threaded rod 3 is mounted on the protective housing for lateral rotation 1, and the left end of the threaded rod 3 is driven and rotated by a stepper motor 6 fixed on the outside of the protective shell 1, the threaded rod 3 is threaded and engaged by a threaded sleeve 5, and the threaded sleeve The lower end of the tube 5 is slidably connected with the limit rod fixed in the protective shell 1; the secondary displacement assembly 2 is arranged above the threaded sleeve 5; the lower end of the protective shell 1 is provided with a positioning plate 4, and , the positioning plate 4 is provided with a plurality of threaded holes for fixing the device;

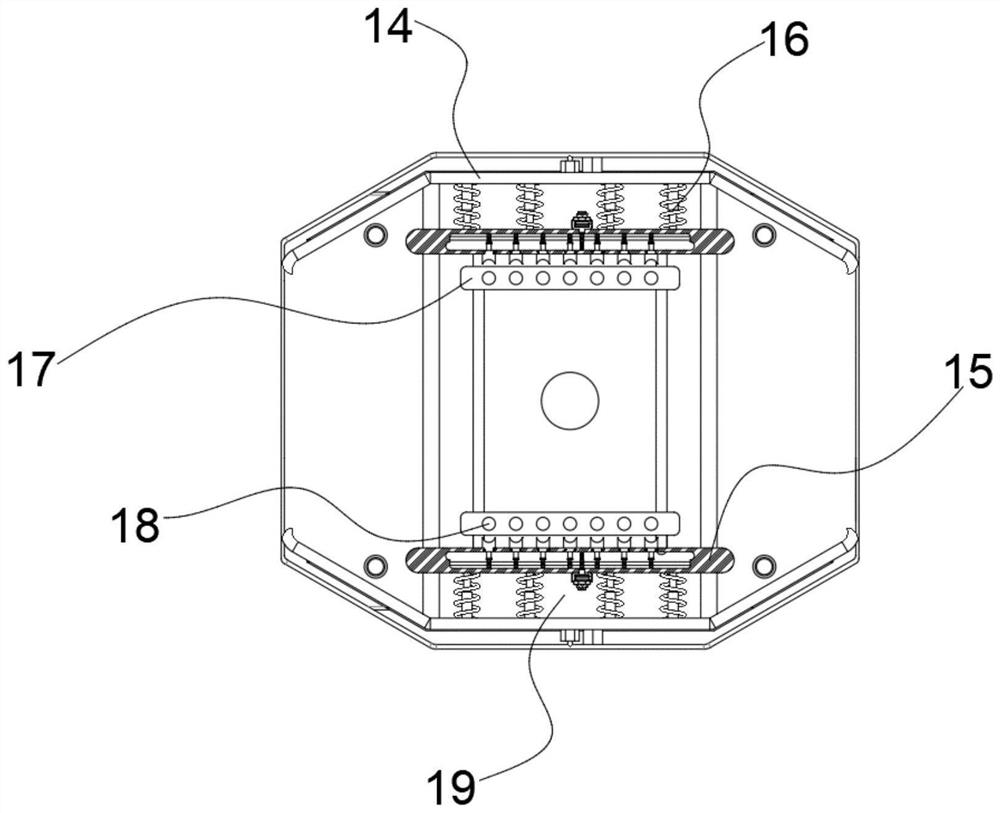

[0038] A cushioning device 13 is also provided between the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com