A method for diagnosing control performance of a semiconductor process batch-to-batch control system

A control system and control performance technology, applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve problems such as difficult to determine control performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

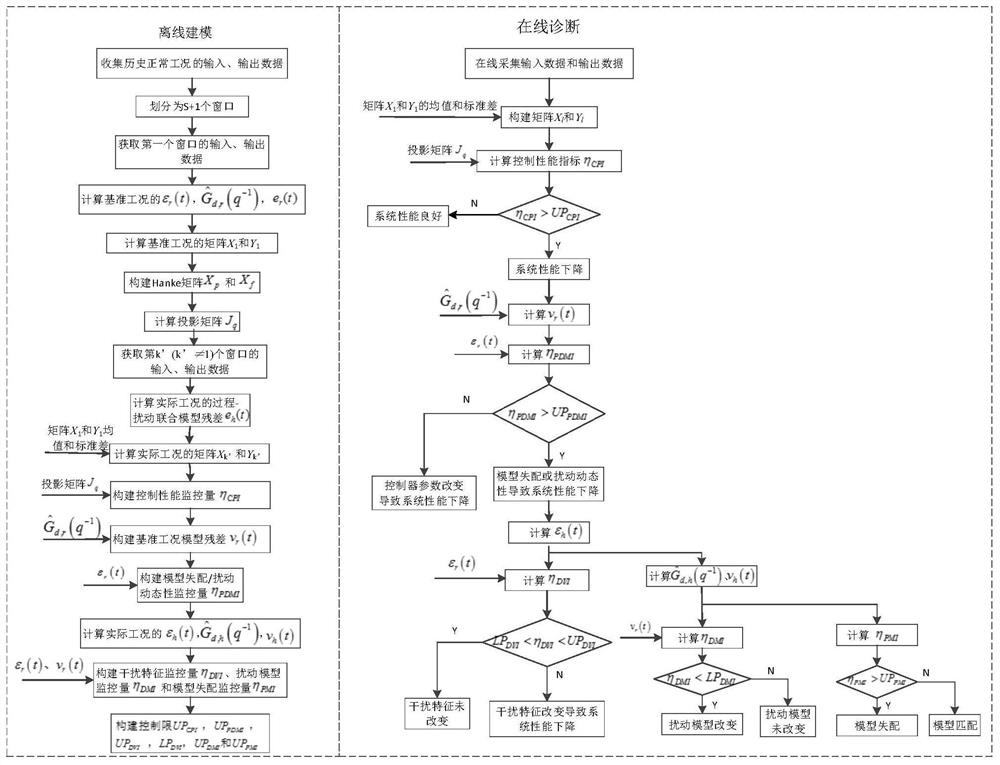

Method used

Image

Examples

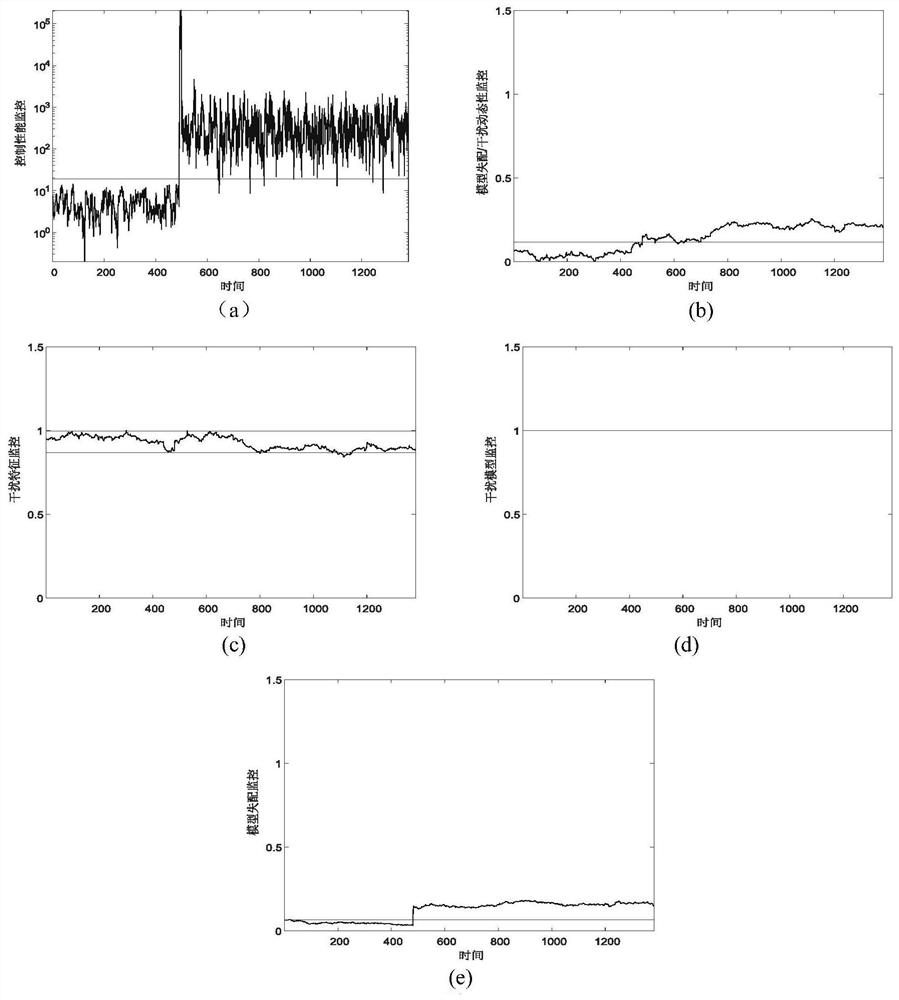

specific example 1

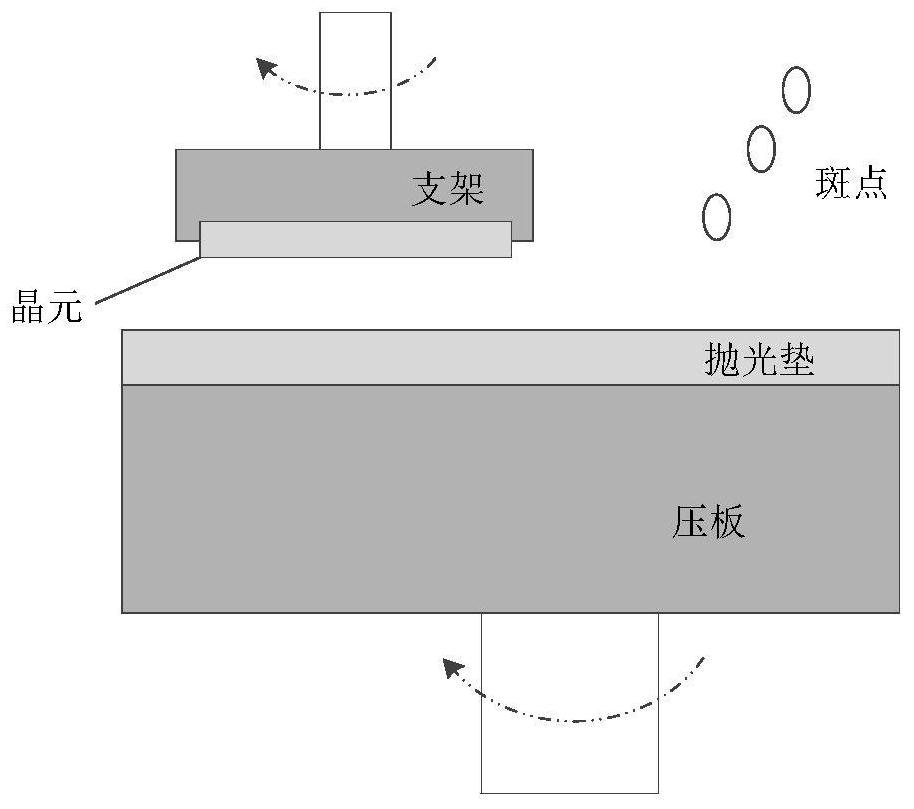

[0206] Chemical-mechanical planarization (CMP) is the planarization method chosen by the semiconductor industry today. figure 2 shown. In 1989, Davari et al. developed the CMP method for global planarization of interlayer dielectrics. In the early 1990s, IBM successfully used the CMP process to deal with the slow dry etching of copper. In addition, CMP has been integrated with double Damaskin to simplify the fabrication steps of conductive lines between successive layers of multilayer integrated circuits. As wafer sizes increase to 300 mm or more, equipment and process designs improve to address these issues. In addition, due to the increasing demand for high-performance products in the fierce semiconductor market, the quality of semiconductor products is becoming more and more important with the increase of manufacturers. This example uses a simulated CMP process. The discrete model of the CMP process is described as follows:

[0207]

[0208] Among them, θ=0.65, ε(t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com