Packing device for bridge production and using method thereof

A bridge and stacking technology, applied in the field of packaging devices, can solve the problems that manual palletizing cannot meet requirements, manual palletizing is time-consuming and laborious, and efficiency cannot be guaranteed, and achieves the effect of convenient wrapping and hoisting transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

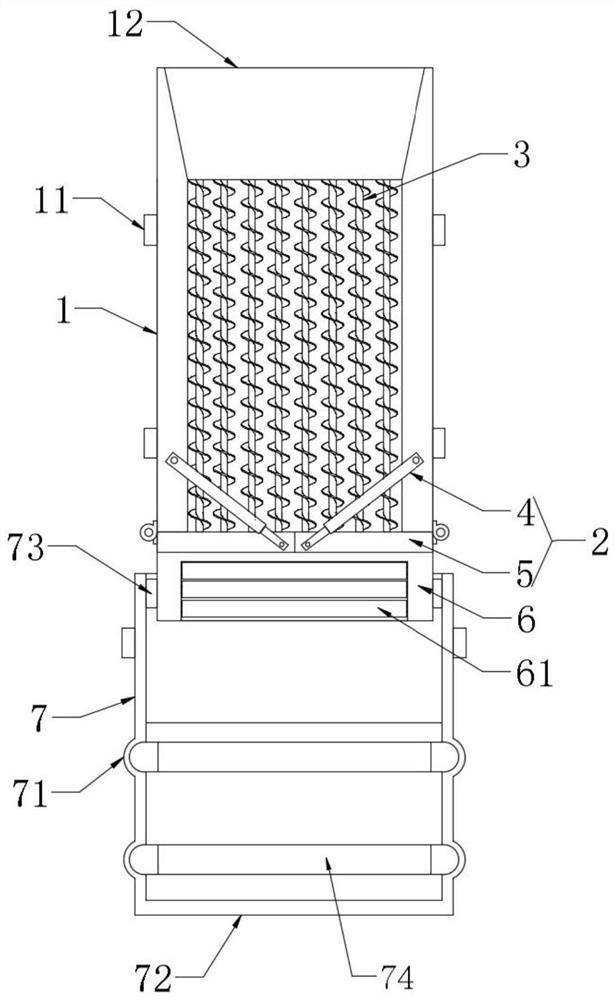

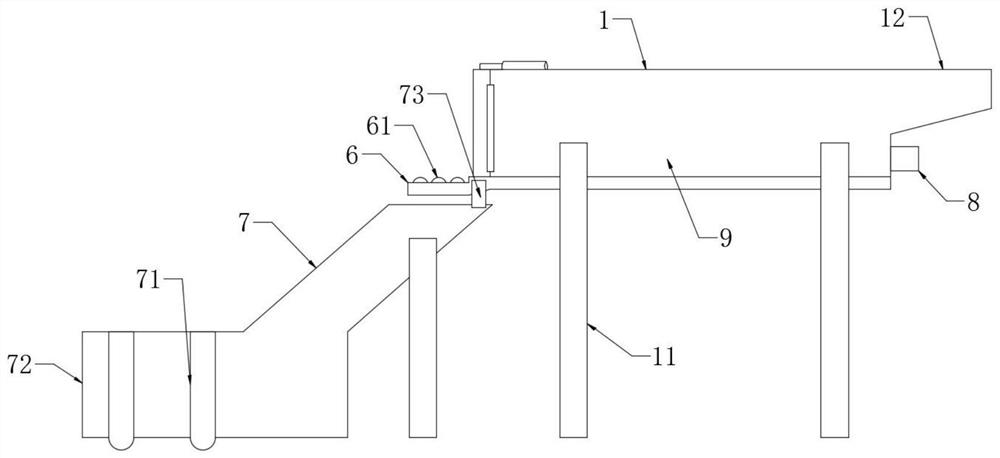

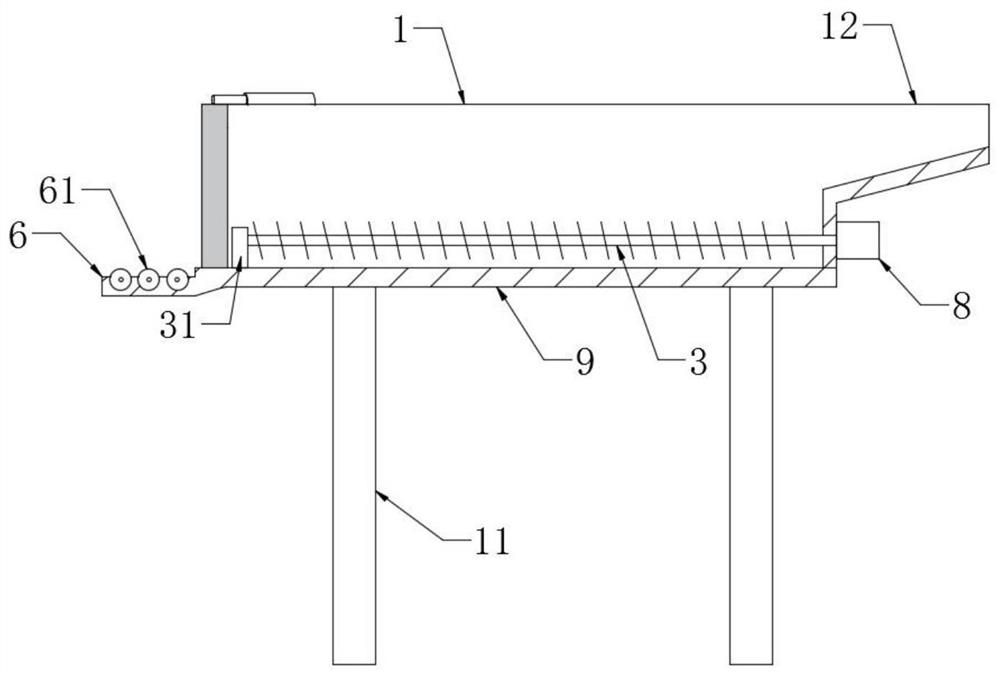

[0035] see Figure 1-Figure 4 , the present invention provides a technical solution: a packaging device for bridge production, including a stacking trough 1, a feeding mechanism 2, a plurality of screw shafts 3 arranged side by side, and a packing slot 7, and a plurality of screw shafts 3 are arranged in the pile At the bottom of the material chute 1, the feeding mechanism 2 is arranged at the outlet of the material storage chute 1, the packing chute 7 is arranged below the outlet of the material storage chute 1, and the bottom of the packing chute 7 is provided with a concave wire binding groove 71, which solves the problem of In the past, the bridge tray production process could not be effectively palletized.

[0036] As an embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com