Enamelled wire take-up device

A wire take-up device and enameled wire technology, which is applied in the direction of packaging and binding machine parts, etc., can solve the problems of inconvenient wrapping of enameled wires, paint layer damage, and affecting the relative stability between coils, so as to reduce the relative movement trend and reduce friction , the effect of easy bandaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

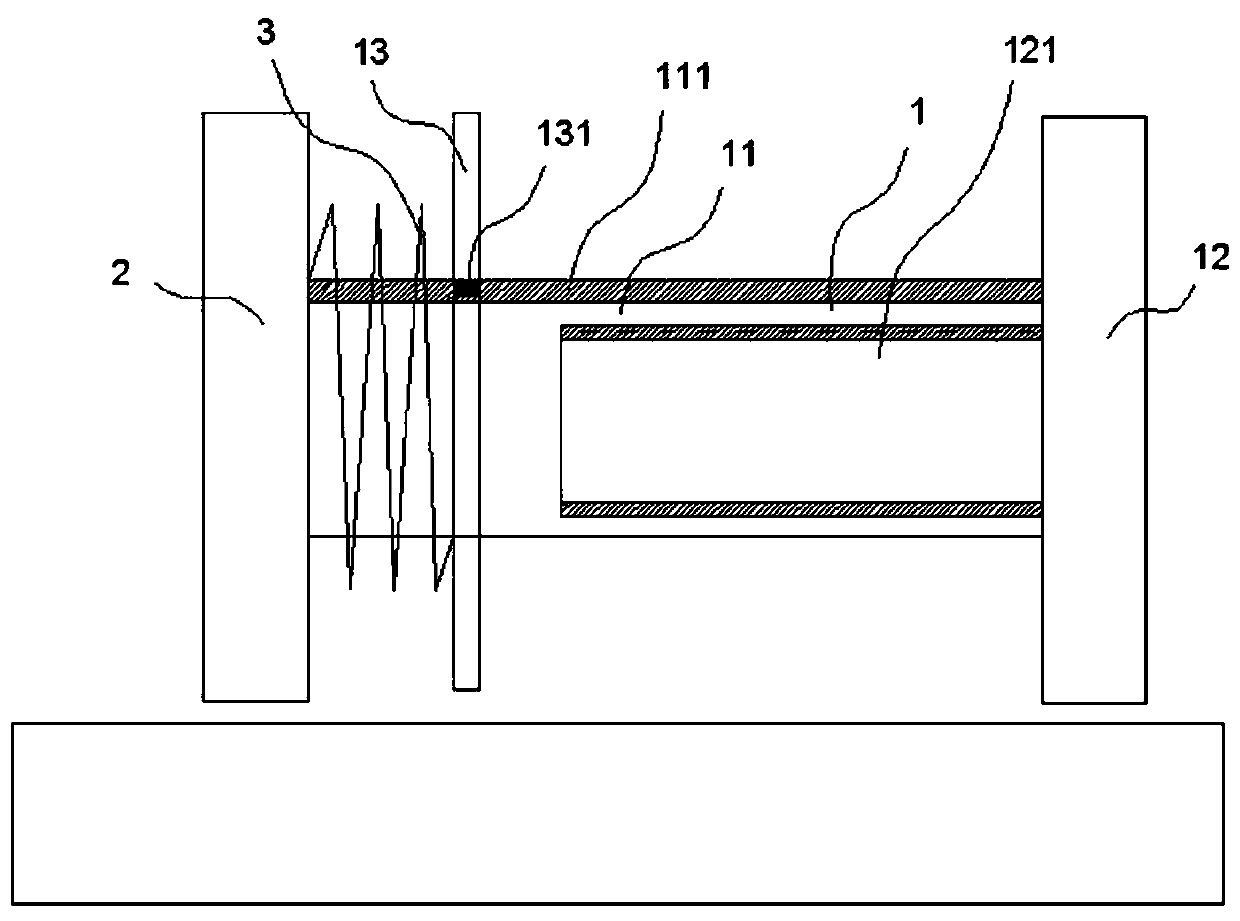

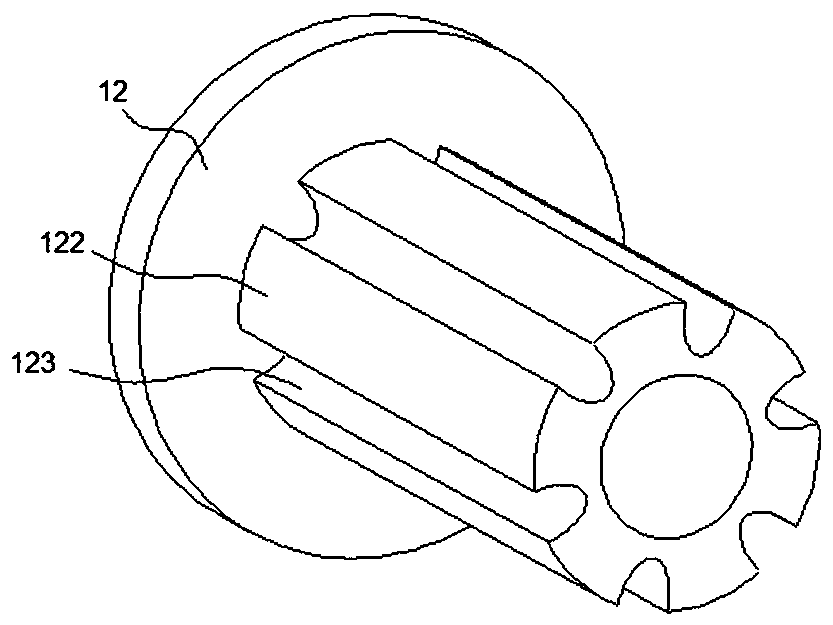

[0015] Such as figure 1 with figure 2 The enameled wire take-up device shown includes a base on which a drum 1 is arranged, and the drum 1 includes a cylinder 11, a first baffle 12 located at the end of the cylinder 11 and a sleeve sleeved on the cylinder 11. The second baffle plate 13, the base is provided with a limiting plate 2 parallel to the first baffle plate 12, a spring 3 is arranged between the second baffle plate 13 and the limiting plate 2, and the cylinder 11 is provided with a spring 3 parallel to the column. A groove 111 on the axis of the body 11 , and the second baffle 13 includes a protrusion 131 located in the groove 111 . The second groove 111 slides along the guide rail and rotates under the action of the drum 1 . Lubricating oil is provided in the groove 111 . The spring 3 pushes the second baffle plate 13 to squeeze the wou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com