An edible mushroom bag filling mechanism

An edible fungus and feeding mechanism technology, which is applied in the fields of application, horticulture, and botanical equipment and methods, can solve the problems of high labor intensity, affect quality, inconvenience, etc., and achieve convenient and fast operation, convenient dressing, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

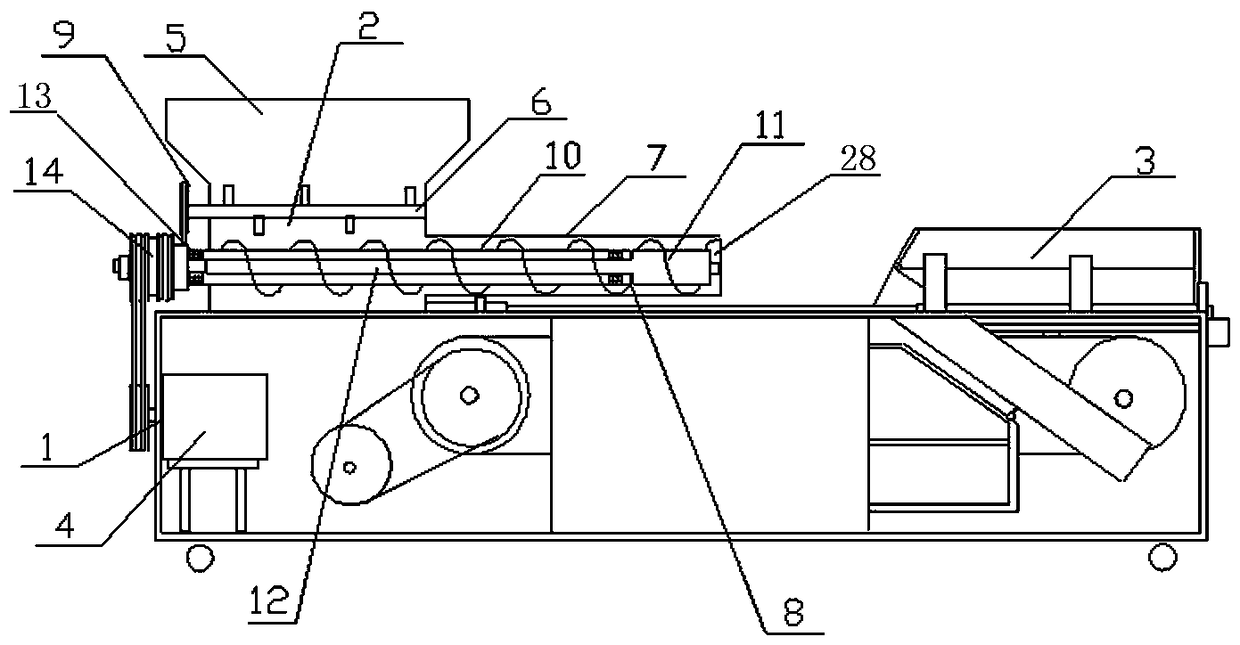

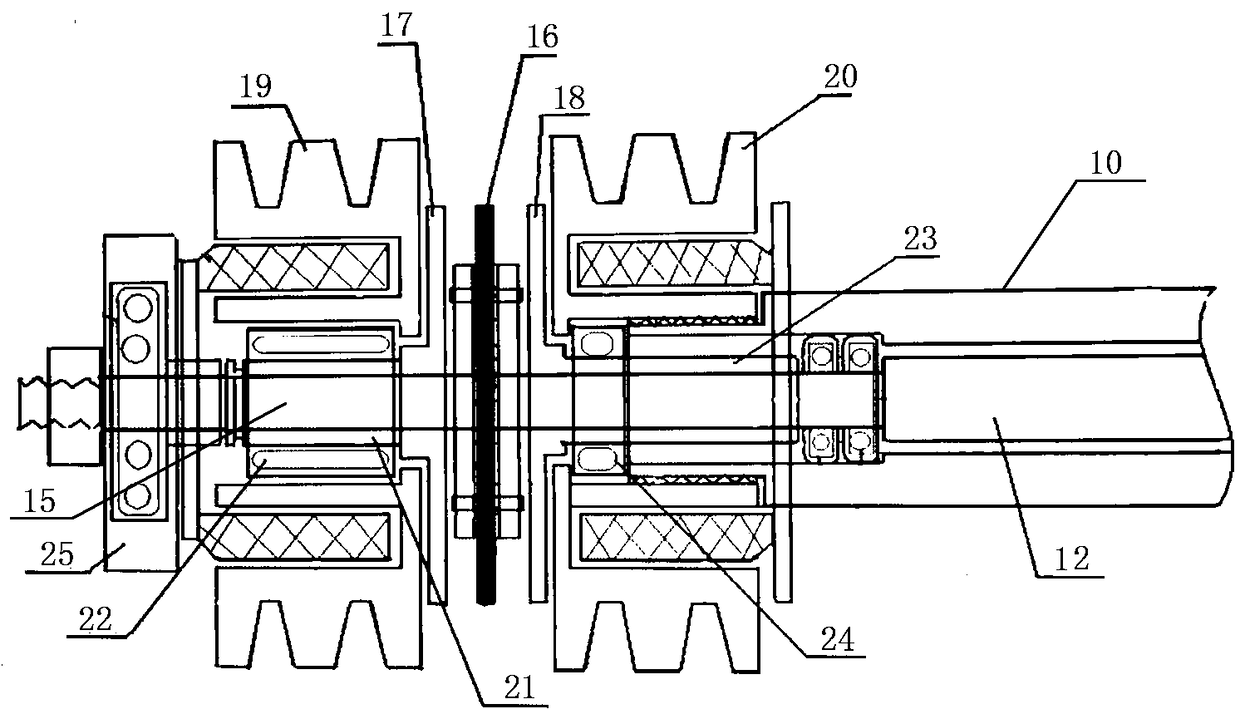

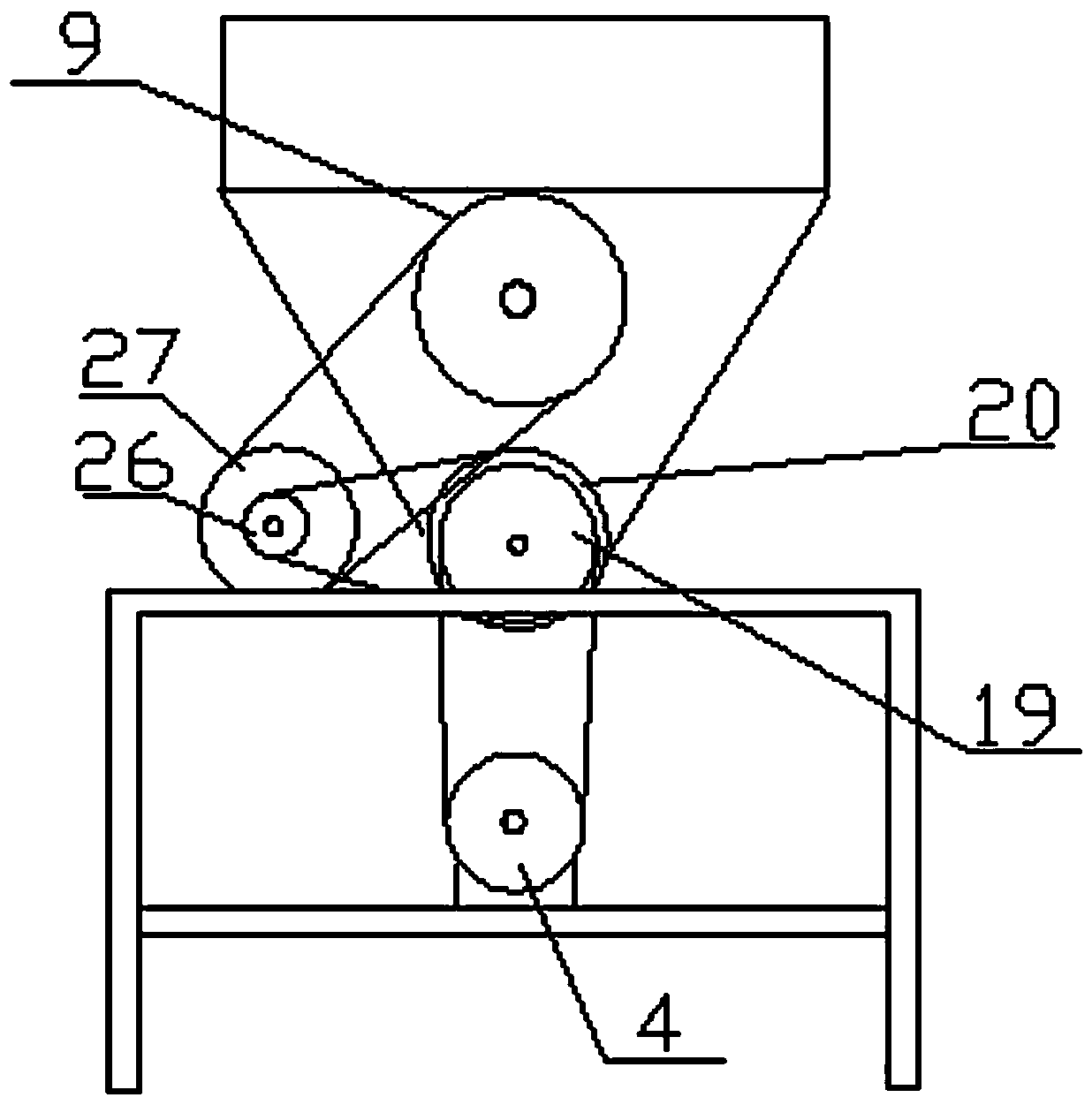

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-3 Shown: a kind of edible mushroom bag filling mechanism, including frame 1, feeding mechanism 2, anti-expansion cylinder 3, described frame 1 left end inside is provided with motor 4, and described frame 1 left end top is provided with Feeding mechanism 2, described feeding mechanism 2 is made up of hopper 5, material mixing shaft 6, discharge cylinder 7, screw pusher shaft 8, and described hopper 5 is provided with mixing shaft 6, and one end of mixing material shaft 6 is provided with There is a driven gear 9, the bottom end of the hopper 5 is provided with a discharge cylinder 7, and the discharge cylinder 7 is provided with a screw push shaft 8, and the screw push shaft 8 is composed of a main screw shaft 10 and a secondary screw shaft 11 Composition, the left end of the auxiliary screw shaft 11 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com