Adjustable horizontal hole protective cover plate

A protective cover and adjustable technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult sorting and recycling of formwork, poor fixing effect of blocking formwork, and loss of safety protection, etc., to achieve Good fixed protection effect, good safety protection effect, and the effect of reducing manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

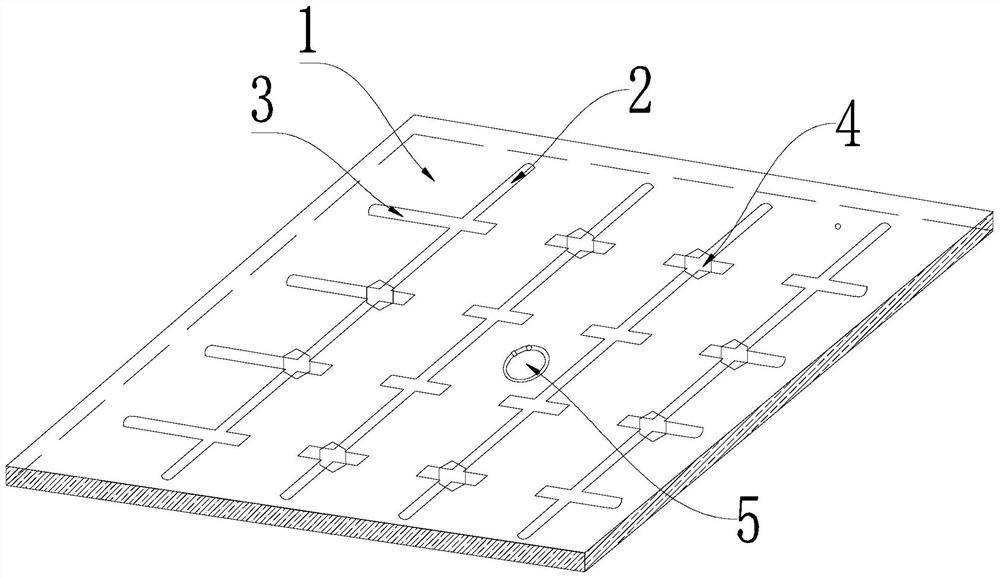

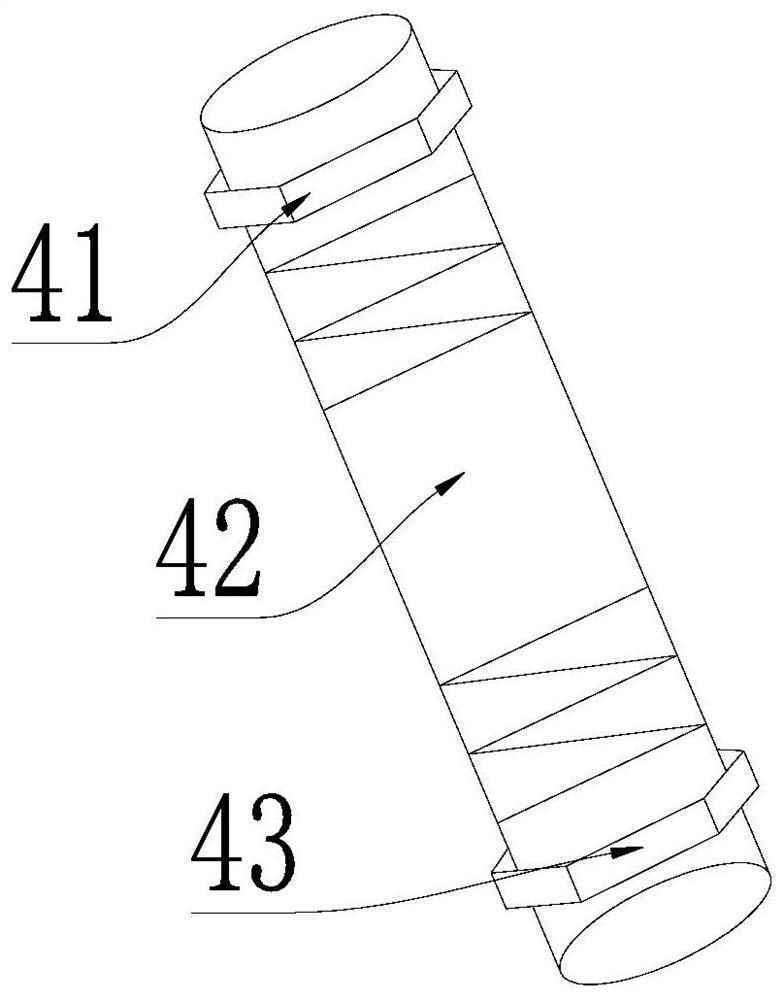

[0025] Example 1: See figure 1 with figure 2 , an adjustable horizontal hole protection cover plate in this embodiment, the cover plate 1 is provided with a vertical adjustment groove 2, and the vertical adjustment groove 2 is provided with an adjustment stop bolt 4, and the adjustment stop bolt 4 and the vertical adjustment groove 2 Fixed by the nut, the vertical adjustment groove 2 is used to adjust the longitudinal coordinates of the adjustment stopper 4, one end of the adjustment stopper 4 is provided with a first fixing nut 43 for resisting the hole, and the other end is provided with a first fixing nut 43 for vertical adjustment. The second fixing nut 41 fixed in the slot 2, the number of adjusting stop bolts 4 is multiple, and the first fixing nut 43 is engaged in the opening; it is used for small rectangular openings of different sizes (long and short sides 100mm-500mm range) ) adjustable protective cover 1, and meet the requirements that the cover 1 is not easy to m...

Embodiment 2

[0026] Embodiment 2: The center position of the cover plate 1 of this embodiment is provided with a pull ring 5 for hanging and pulling the cover plate 1. The number of vertical adjustment grooves 2 in this embodiment is multiple, and they are arranged on the cover plate 1 in parallel. The vertical adjustment slot 2 is fixed. The number of vertical adjustment grooves 2 in this embodiment is four, and the number of adjustment stoppers 4 on each vertical adjustment groove 2 is two. In this embodiment, the vertical adjustment groove 2 is provided with a horizontal sub-groove 3, which is perpendicular to the vertical adjustment groove 2 and communicates with each other. The horizontal sub-groove 3 is used to adjust the horizontal coordinate of the adjustment bolt. In this embodiment, there are multiple transverse sub-slots 3 , which are arranged in parallel on the vertical adjustment slots 2 . The number of transverse sub-grooves 3 in this embodiment is four, and transverse sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com