Ash bucket ash discharging device for boiler

An ash hopper and boiler technology, applied in lighting and heating equipment, etc., can solve the problems of large impact energy release, strong impact force, safety accidents, etc., and achieve the effect of improving fluidity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

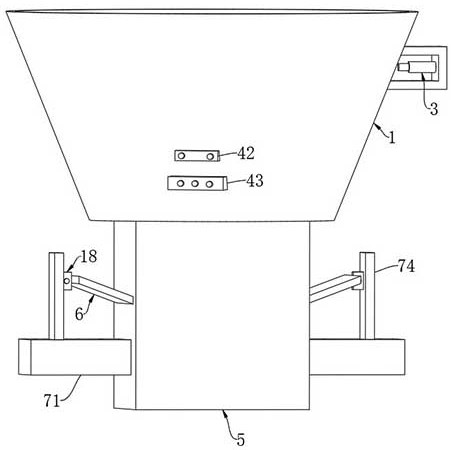

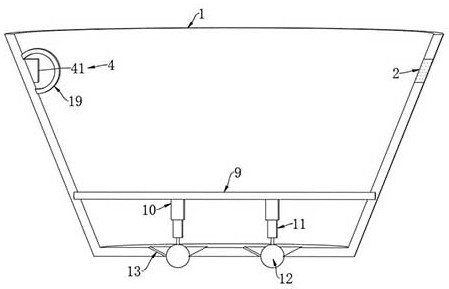

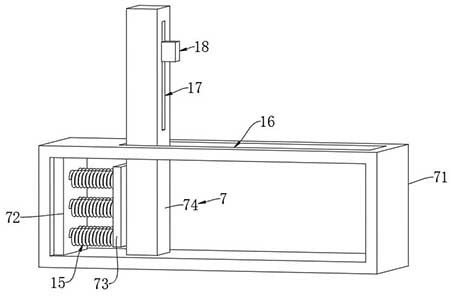

[0030] Such as Figure 1-5 As shown, an ash hopper ash-releasing device for a boiler includes an ash hopper 1, and a light-transmitting glass 2 is embedded on the side wall of the ash hopper 1, and the outer side wall of the ash hopper 1 is fixedly connected with the light-transmitting glass 2. Cooperating light pen 3, the ash hopper 1 is provided with a photosensitive mechanism 4 matched with the light pen 3, the photosensitive mechanism 4 includes a photosensitive resistor 41, an electromagnetic relay 42 and a power-off delay relay 43, and the photosensitive resistor 41 is arranged on the ash hopper 1 , and the photoresistor 41 is arranged opposite to the light pen 3, the electromagnetic relay 42 and the power-off delay relay 43 are all arranged on the outer wall of the ash hopper 1, and the photoresistor 41, the electromagnetic relay 42 and the power-off delay relay 43 The outer wall of the photoresistor 41 is provided with a transparent protective cover 19, and the transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com