Skid-mounted mvr evaporation device

An evaporation device, skid-mounted technology, applied in the field of skid-mounted MVR evaporation device, can solve the problem of low waste heat utilization efficiency of the MVR evaporation and concentration system, the inability to realize the miniaturization of the MVR evaporation and concentration system, and the easy scaling of the MVR evaporation and concentration system, etc. problems, achieve the effect of reducing the risk of fouling, obvious energy saving effect, and avoiding frequent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

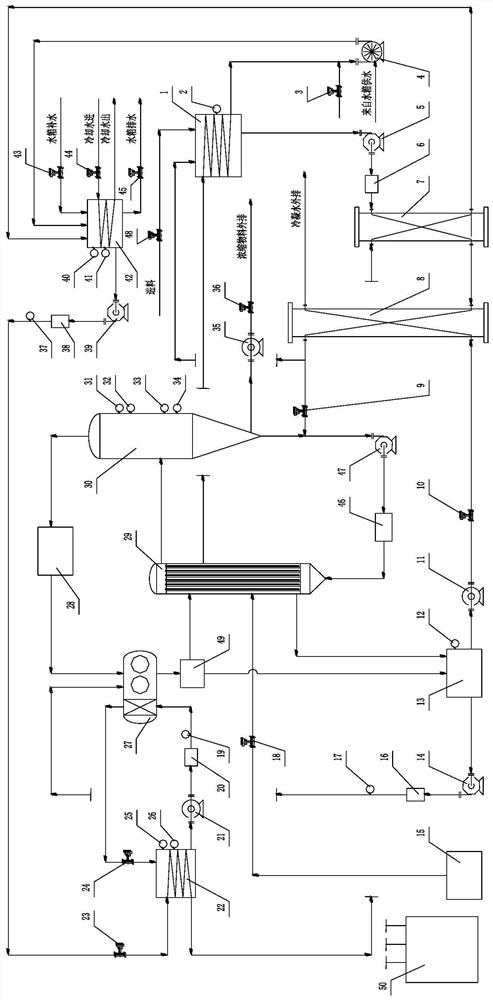

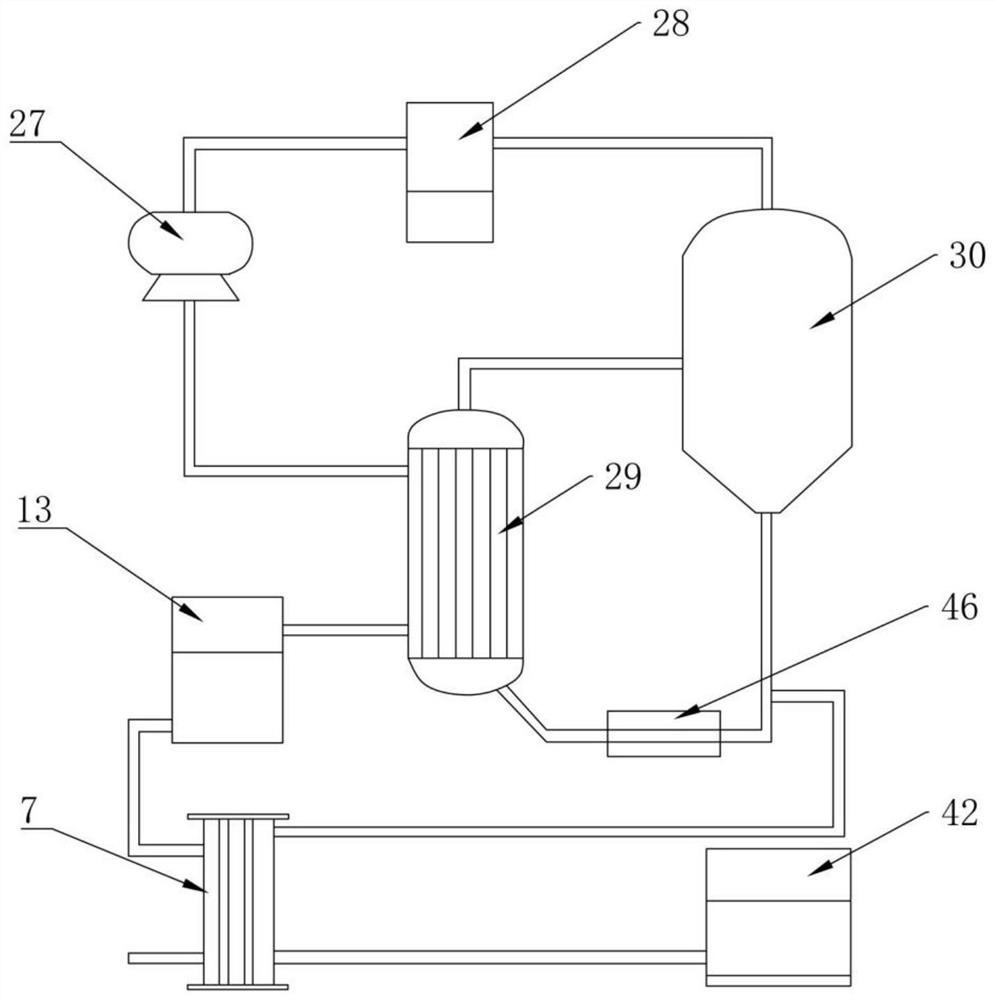

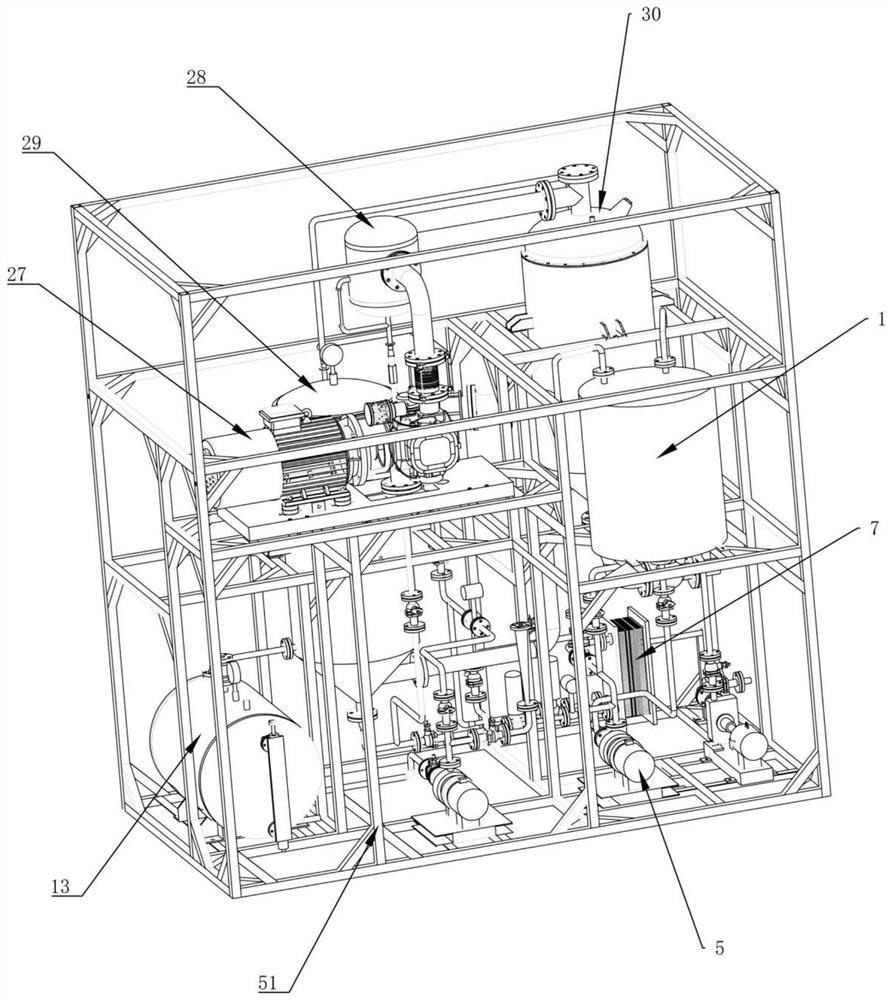

[0052] to combine Figure 1-Figure 7 As shown, this embodiment provides a skid-mounted MVR evaporation device, including a raw material supply system, an evaporation circulation system, a vacuum system, and a waste heat recovery system. The raw material supply system includes a raw material tank 1 and a preheater, and the evaporation circulation system includes an evaporator 29. Separator 30, steam generator 15, steam filter 28 and compressor 27. The vacuum system includes a vacuum pump 4. The waste heat recovery system includes a water tank 42. The material in the raw material tank 1 enters the preheater for preheating. After the material is preheated Enter the evaporato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com