Test device and test method for simulating steel bar corrosion in different environments

A technology of steel corrosion and test device, which is applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve problems such as large fluctuation, poor stability, and inability to determine key factors.

Pending Publication Date: 2021-08-06

SOUTHEAST UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, due to the large fluctuation and poor stability of the external natural environmental conditions, the obtained test results are poorly repeatable and the key factors affecting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

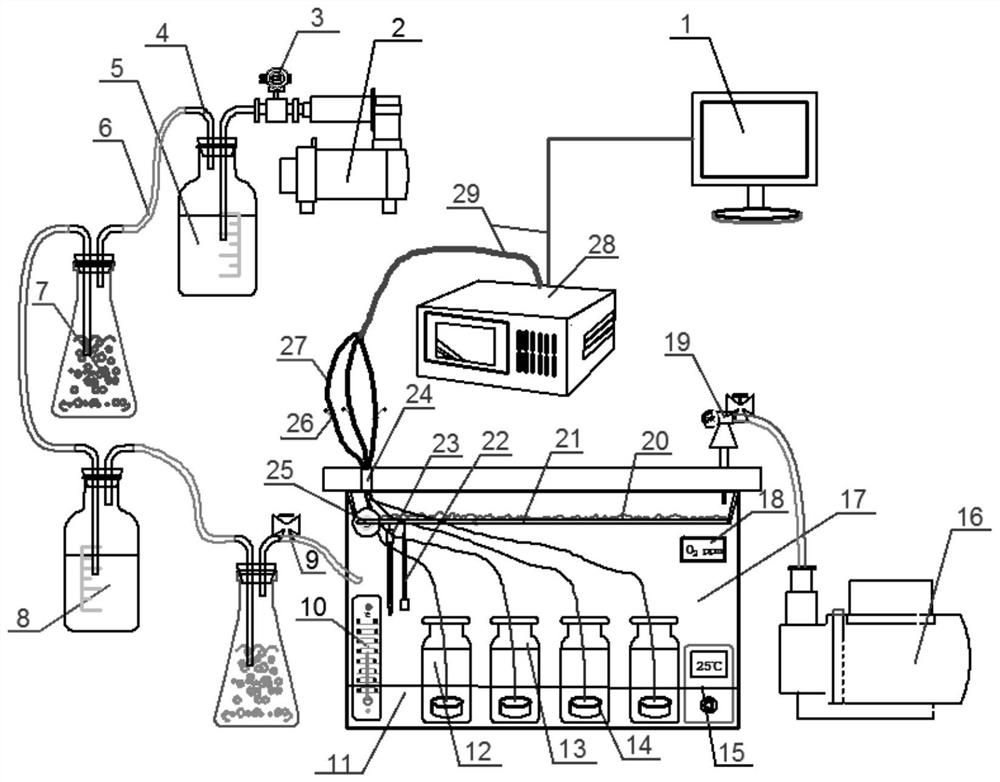

The invention discloses a test device and a test method for simulating steel bar corrosion in different environments, the test device comprises a sealing box, a plurality of electrolytic tanks with simulation liquid are arranged in the sealing box, and working electrode-steel bar samples are placed in the electrolytic tanks; a reference electrode and an auxiliary electrode are arranged above the electrolytic tanks, and the reference electrode and the auxiliary electrode are controlled to enter different electrolytic tanks when the steel bar corrosion process is regularly measured; and the voltage-stabilizing galvanostat and the electrochemical test computer acquisition equipment are connected outside the electrolytic tank and are used for monitoring the time-varying rule of steel bar corrosion in different periods. According to the invention, the problems of large test result difference, poor repeatability and the like caused by complexity and instability of current sample storage environment conditions are solved; the key factors of steel bar corrosion are accurately mastered by controlling external condition variables, and meanwhile, the influence degrees of different factors on the steel bar corrosion process are selectively controlled according to the required test conditions.

Description

technical field [0001] The invention relates to a corrosion monitoring technology for simulating steel bars under targeted environmental conditions, in particular to a test device and a test method for simulating steel bar corrosion in different environments. Background technique [0002] Due to its good mechanical properties and workability, steel bars have become the most extensive and important engineering materials in the chemical industry, petrochemical industry, transportation and other fields, and their main components are metal elements or alloys. However, corrosion of steel bars is the most important and direct cause of failure of large-scale building structures, civil infrastructure, transportation equipment, and instruments. The resulting annual losses far exceed the comprehensive economic losses such as floods and fires. According to a survey in the United States, the cost of corrosion in the United States is 6 cents per dollar of GDP. Globally, this equates to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N17/00G01N17/02

CPCG01N17/006G01N17/002G01N17/02

Inventor 刘加平王潇舷吕晨周义川

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com