Direct current converter and control circuit and method for the direct current converter

A DC converter and control circuit technology, applied in the direction of converting DC power input to DC power output, control/regulation systems, instruments, etc., can solve the influence of slope compensation signal switch duty cycle, the peak value change of inductor current, and the maximum output current. restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

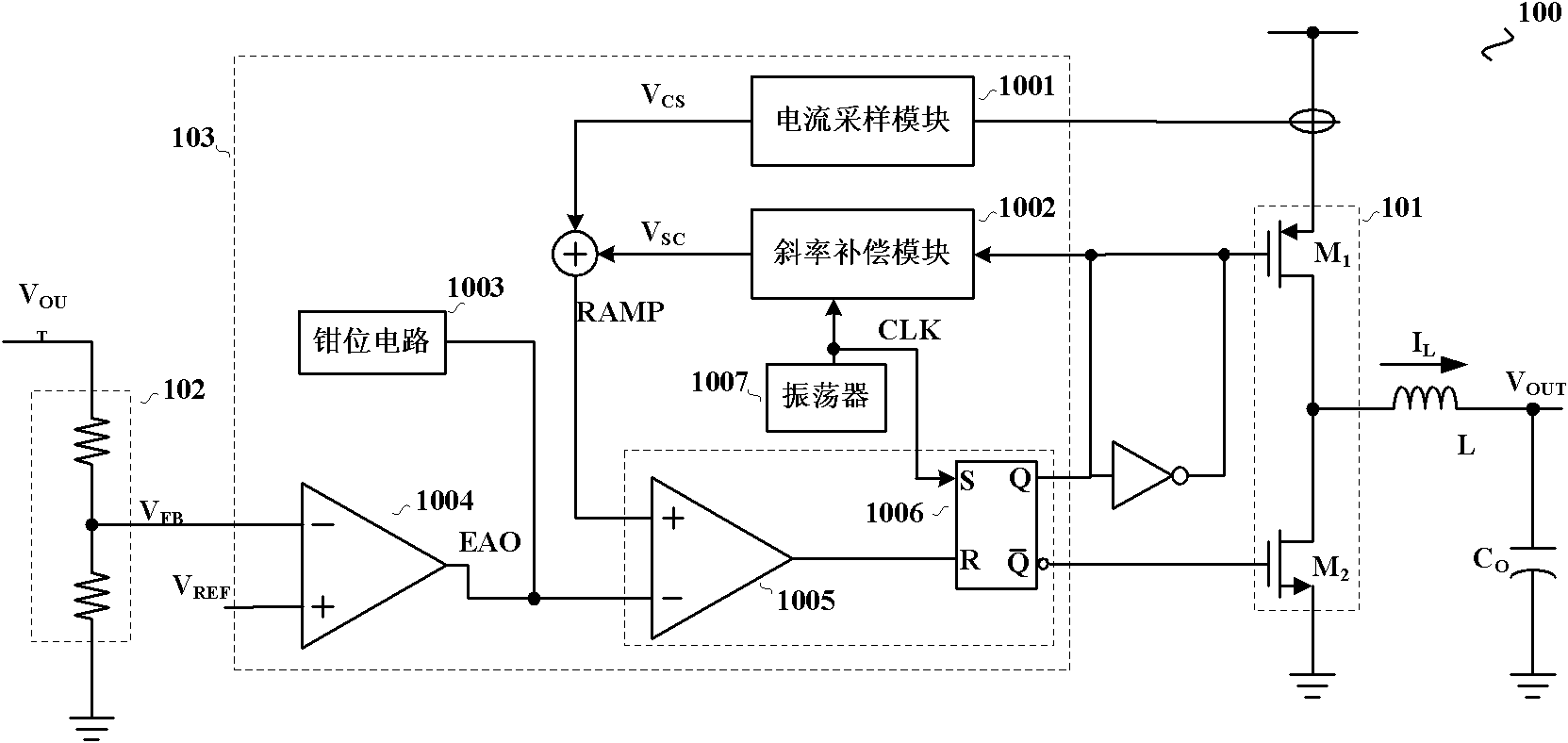

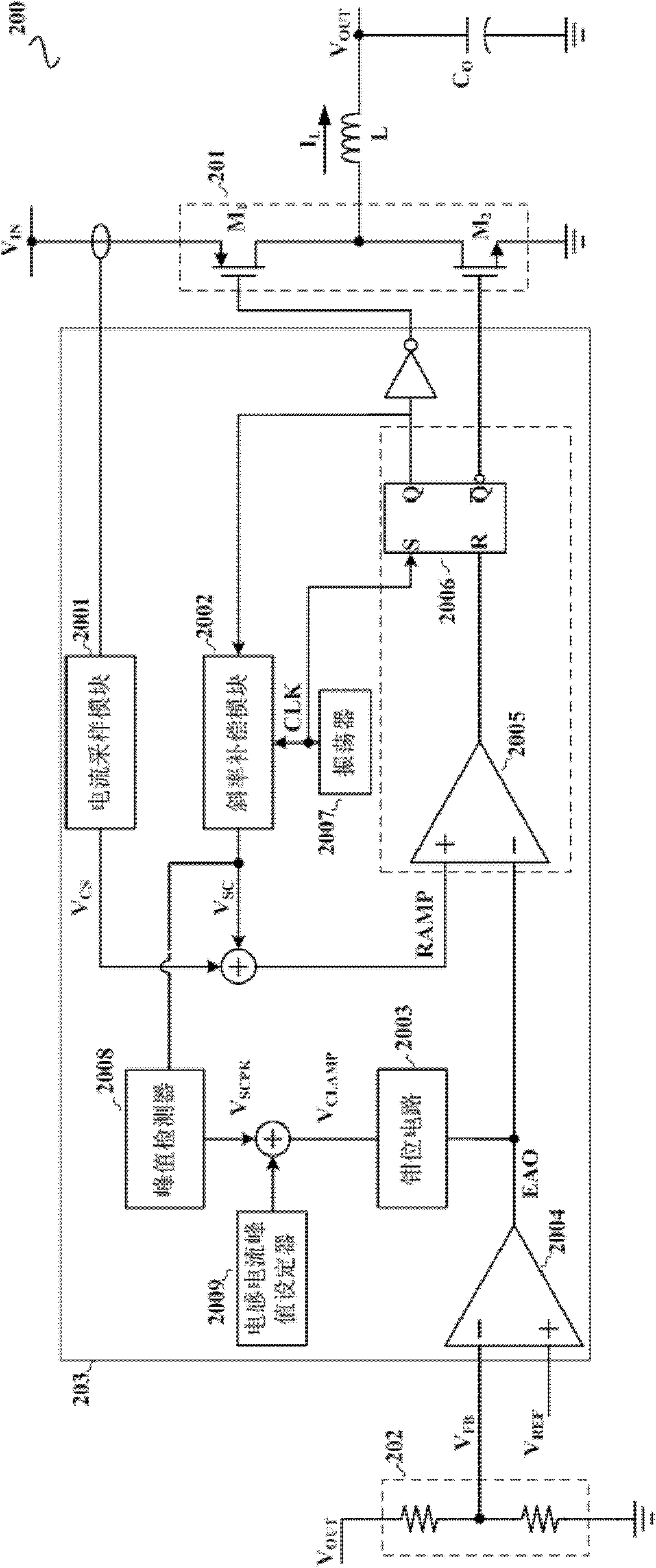

[0030] refer to image 3 , is a DC converter 200 according to an embodiment of the present invention. Such as image 3 As shown, the DC converter 200 includes an output stage 201 coupled between the input terminal of the DC converter 200 and the ground; the inductor L and the output capacitor C O The composed LC filter is coupled to the output stage 201; the feedback circuit 202 is used for output voltage V of the DC converter 200 OUT , providing the feedback signal V FB ; and the control circuit 203, coupled to the feedback circuit 202 and the output stage 201, to receive the feedback signal V FB , reference signal V REF and the inductor current signal I L , providing a control signal to the output stage 201 . In one embodiment, the output stage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com