Cooker cover of electric pressure cooker

A technology of electric pressure cooker and pot cover, which is applied in the direction of pressure cooker, etc., and can solve the problem of single exhaust speed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

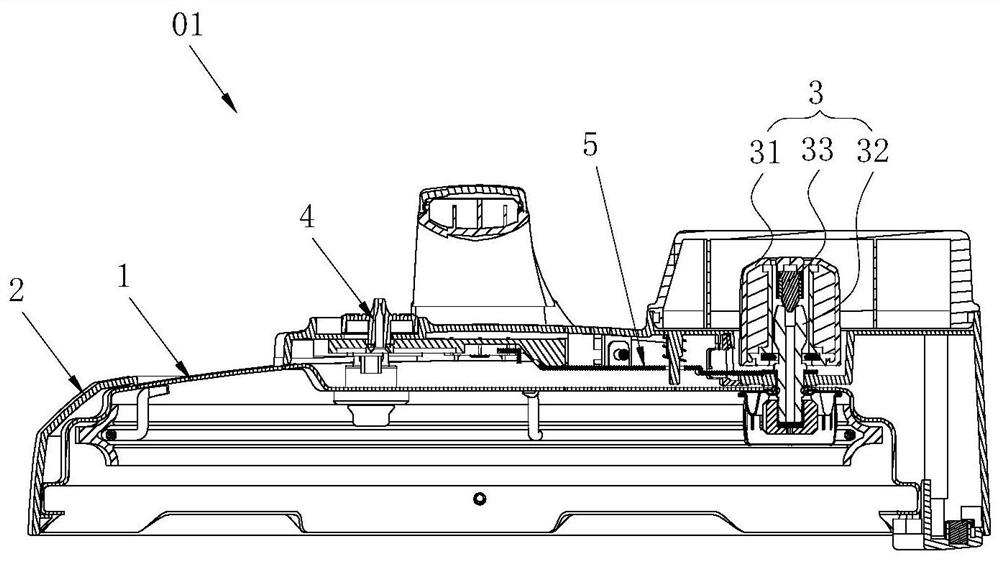

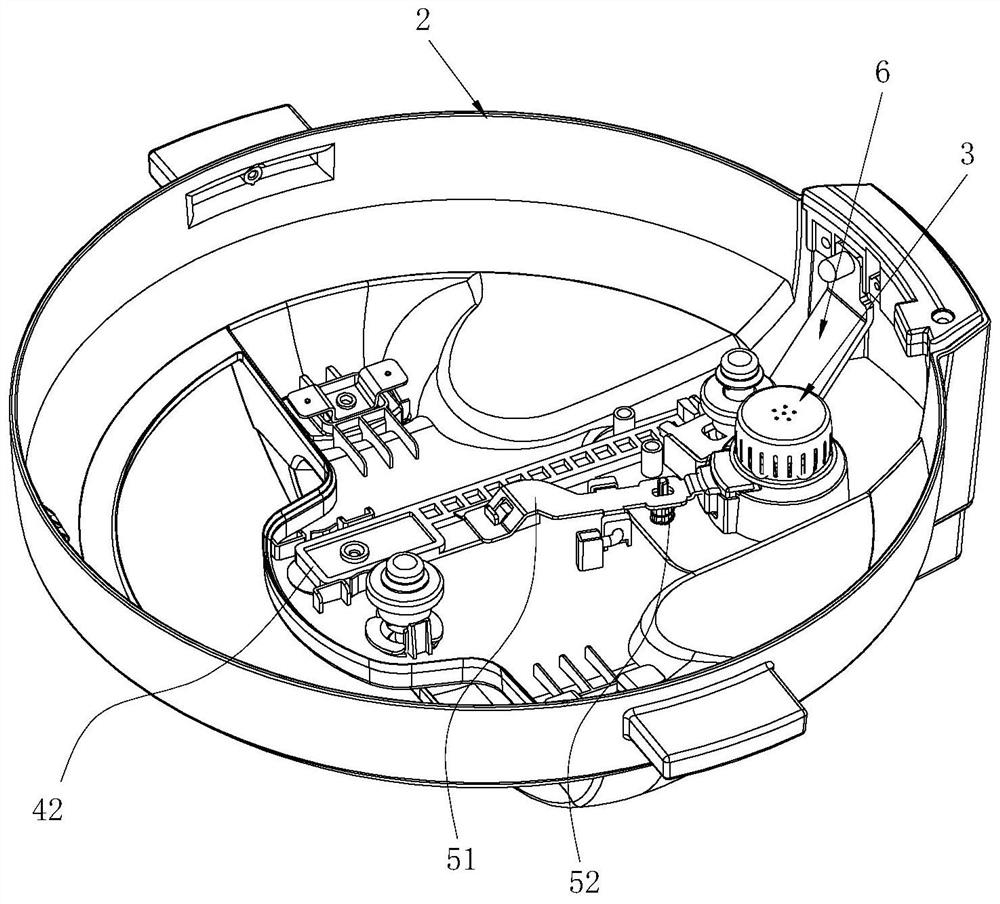

[0049] see Figure 1 to Figure 9 , a lid 01 for an electric pressure cooker according to Embodiment 1 of the present invention, the lid 01 comprising:

[0050] Steel cover 1:

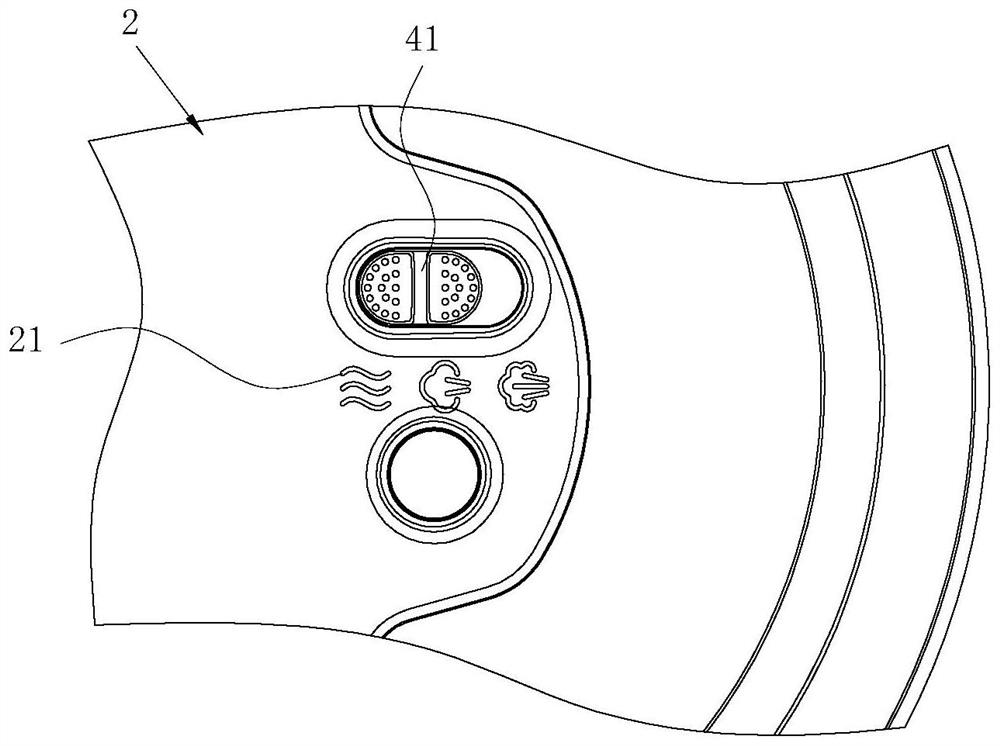

[0051] A face cover 2, the face cover 2 is arranged on the steel cover 1 and is located outside the steel cover 1;

[0052] Pressure limiting valve 3, the pressure limiting valve 3 is arranged on the steel cover 1, the pressure limiting valve 3 includes an exhaust pipe passing through the steel cover 1 and a valve whose lower end is arranged in the exhaust pipe Piston 33, the position of the valve piston 33 relative to the exhaust pipe achieves different exhaust speeds;

[0053] A manipulation component 4, the manipulation component 4 is movably arranged on the face cover 2, and the manipulation component 4 includes a manipulation member exposed to the face cover 2;

[0054] A linkage assembly 5, the linkage assembly 5 connects the valve piston 33 and the control member and makes the valve piston 33 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com