A core wire stripping tool table

A technology for stripping tools and core wires, which is used in cable installation, disassembly/armoured cable equipment, electrical components, etc. It can solve the problems of irreversibility, waste of staff time, and rough wire peeling methods, saving time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

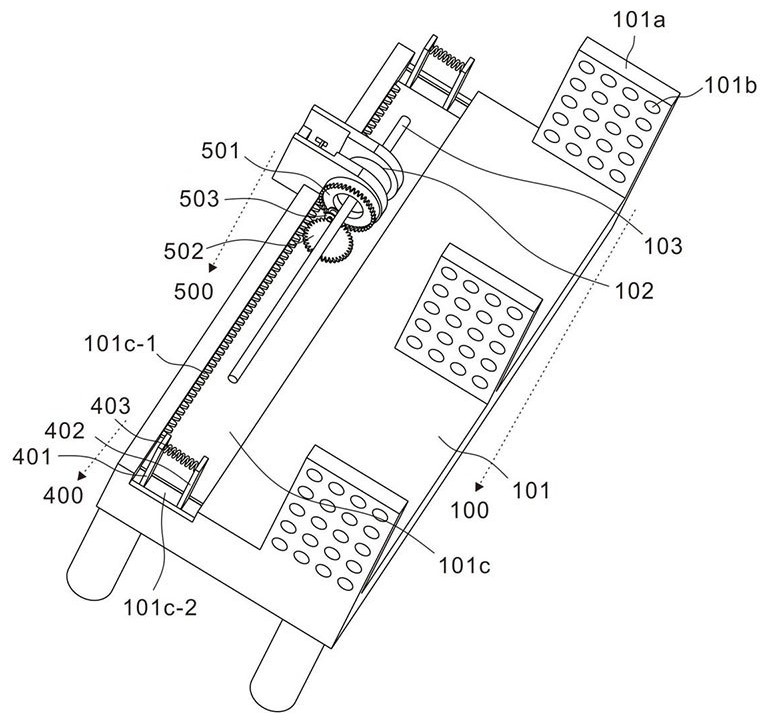

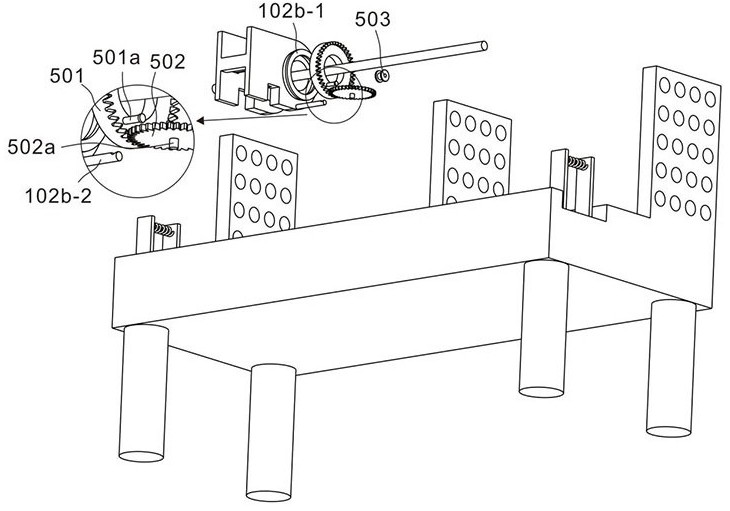

[0030] refer to Figure 1~6 , is the first embodiment of the present invention, which provides a core wire stripping tool table, which includes a processing assembly 100 and a clamping assembly 400 .

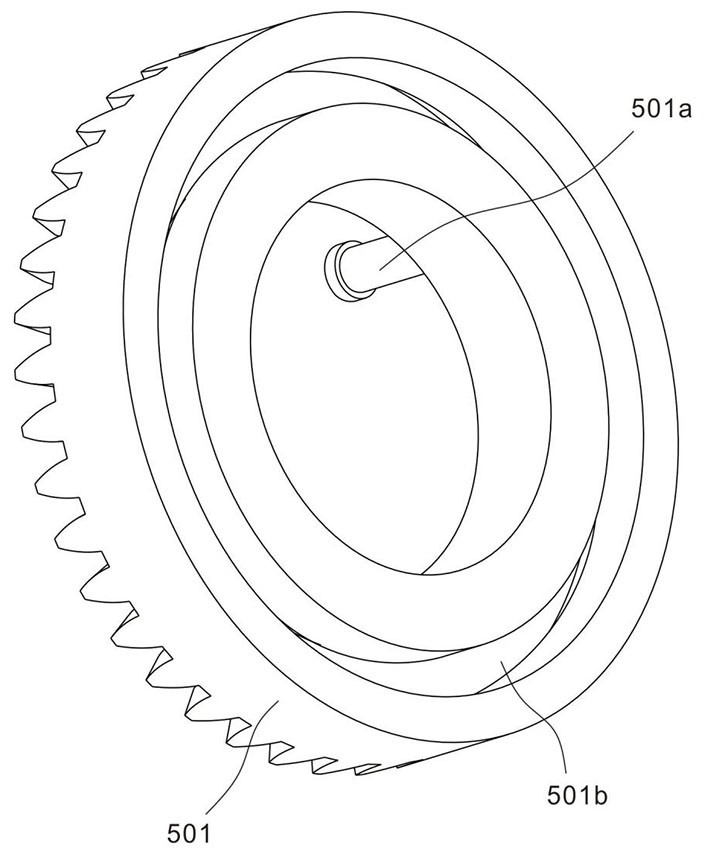

[0031] The processing assembly 100 includes a workbench 101, a cutting part 102 and a core wire 103. Specifically, a partition plate 101a is vertically arranged on the workbench 101, and a plurality of through holes 101b are arranged on the partition plate 101a, and the core wire 103 to be processed can pass through Hanging on the partition plate 101a through the through hole 101b, a guide groove 101c is arranged horizontally on the workbench 101, and the guide groove 101c is close to the edge of the workbench 101 side, and a square chute mouth is provided at the bottom of the cutting part 102, and the cutting part 102 is erected on the edge of the workbench 101 through this chute opening, the main part of the cutting part 102 is located in the guide groove 101c, and the core wi...

Embodiment 2

[0040] refer to Figure 7 , 8 , is the second embodiment of the present invention, which is based on the previous embodiment, and further includes a wire stripping assembly 200 and a control assembly 300 .

[0041] The wire stripping assembly 200 includes a second elastic member 201 and a wire stripping block 202. Specifically, a long groove 102a-1 is arranged on the upper circumference of the first through plate 102a, and the long groove 102a-1 communicates with the circular groove A, and the wire stripping block 202 is installed on In the long groove 102a-1, one end of the second elastic member 201 is fixedly connected to the back of the wire stripping block 202, and the other end is fixedly connected to the end wall of the long groove 102a-1. The end of the wire stripping block 202 facing the core wire 103 is a cutting tip. When 103 is located in the circular groove A and needs to be stripped, the cutting tip of the stripping block 202 is inserted into the core wire 103. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com