Optical cable monitoring method in submarine cable production and laying process based on artificial intelligence

An artificial intelligence and submarine cable technology, applied in electrical components, electromagnetic wave transmission systems, transmission systems, etc., can solve problems such as poor generalization ability, untimely optical cable monitoring, and large manpower input, so as to facilitate fault detection and improve monitoring response The effect of speed and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The specific scenario targeted by the present invention is: the submarine cable production scenario, the optical cable category includes 36 cores, 72 cores, 108 cores and more optical fibers; the factory test data of OTDR has been obtained by default.

[0023] The OTDR sends periodic light pulses to the optical fiber and tests the reflected signal to obtain the backscattering curve. It not only shows the attenuation due to the intrinsic characteristics of the fiber, but also includes sudden changes in the characteristics of the fiber. This sudden change (that is, an event) is usually caused by a connector, a splicing point, a connector, a bend, or other similar events; the OTDR calculates the distance between the event occurrence point and the OTDR device by testing the reflection time of the light wave. Through the detection of the curve, the status of the current route and the quality of the connection point and the connector can be obtained.

[0024] This embodiment...

Embodiment 2

[0036] This embodiment provides an artificial intelligence-based method for monitoring optical cables during the production and laying of submarine cables. On the basis of Embodiment 1, it is possible to quickly measure the on-off monitoring of optical fibers without investing a lot of manpower in testing.

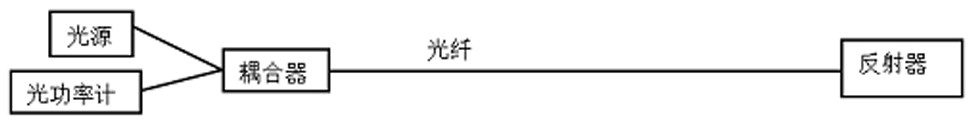

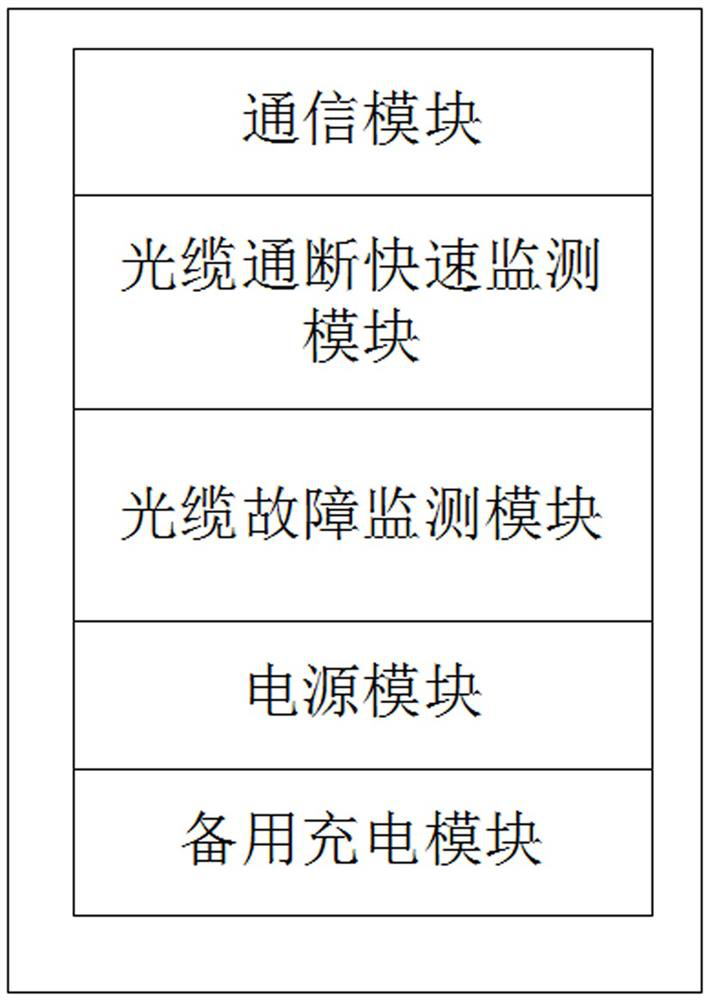

[0037] Specifically, the light source and optical power monitoring instrument (optical power meter) are placed at one end of a single optical fiber through a coupler, and a reflector is deployed at the other end to realize real-time monitoring of fiber on and off. The structure of the optical cable on and off fast monitoring module Such as figure 1 shown. It can simultaneously monitor the overall loss of 36 cores, 72 cores, 108 cores and more optical fibers in real time at the millisecond level. When the overall loss of any one core fiber is abnormal, the alarm can be uploaded to the network management within 5 seconds; compared with existing There is a method that does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com