A printed circuit board with an embedded array of microfluidic channels and its preparation method

A printed circuit board and micro-channel technology, which is applied in the directions of printed circuit manufacturing, printed circuits, printed circuit components, etc., to achieve the effect of increasing integration density and realizing arrayed high-density transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

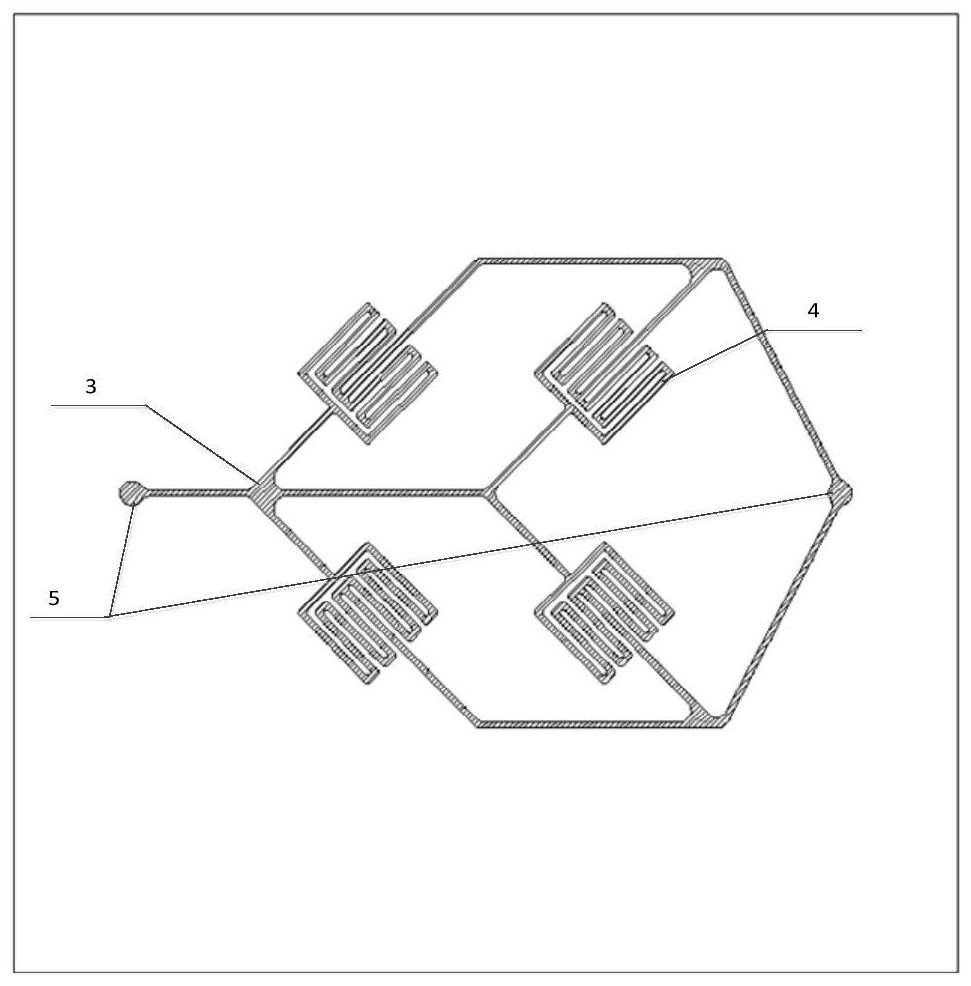

[0047] The size of the liquid inlet and outlet 5 is greater than or equal to the cross section of the shunt network 3 to meet the needs of low flow resistance for liquid supply.

Embodiment 2

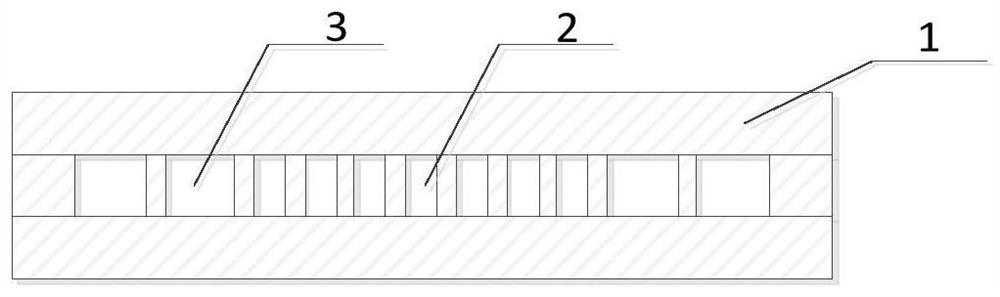

[0053] Step 1: provide a flat and smooth copper core board.

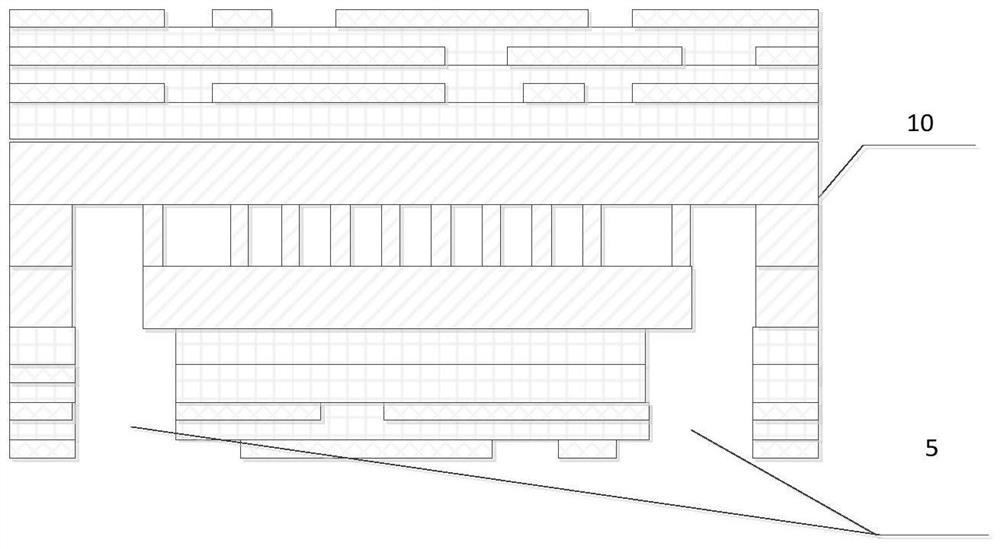

[0056] Step 4: Provide a multi-layer wiring layer on the top of the metal core board prepared by the printed circuit board lamination process.

[0057] Step 5: Provide a multi-layer wiring layer at the bottom of the metal core board prepared by the printed circuit board lamination process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com