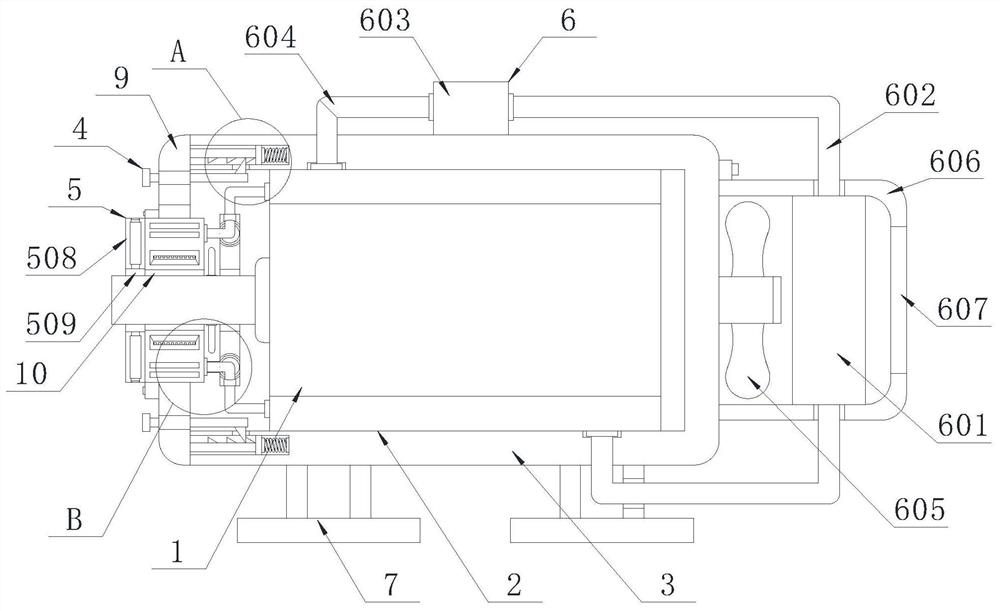

Energy-saving motor with efficient heat dissipation

A heat dissipation mechanism and high-efficiency technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of lack of contact heat dissipation ability, lack of continuous heat dissipation ability, and affecting air circulation, etc., to improve efficient heat dissipation ability and ensure disassembly and assembly portability The effect of ensuring the stability of the assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

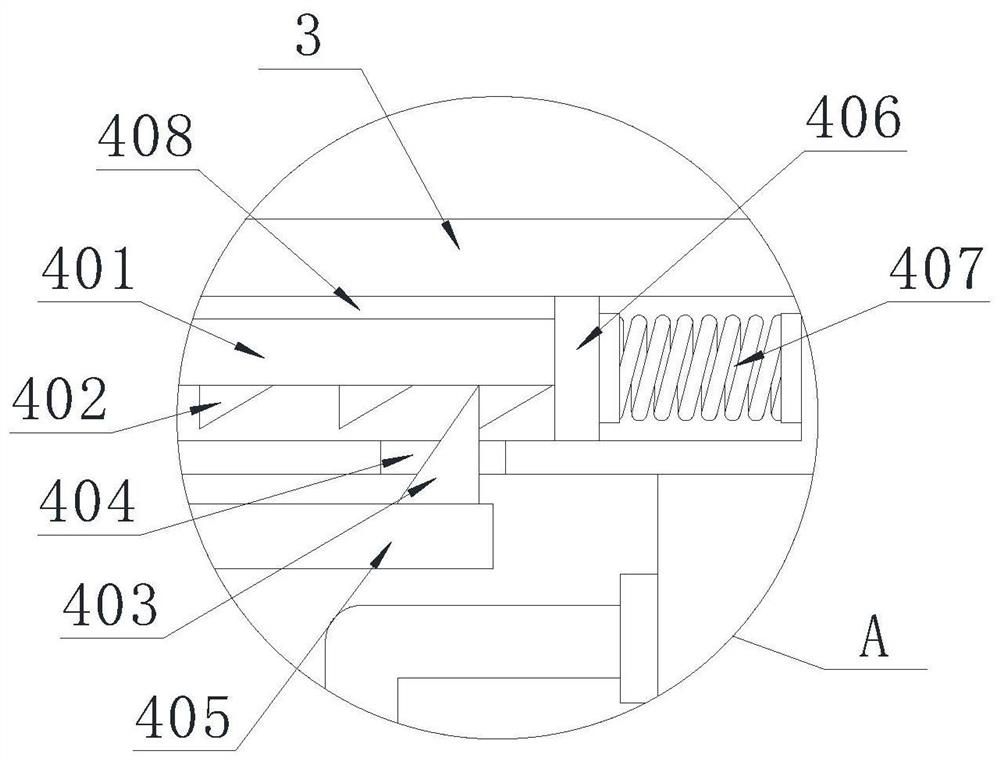

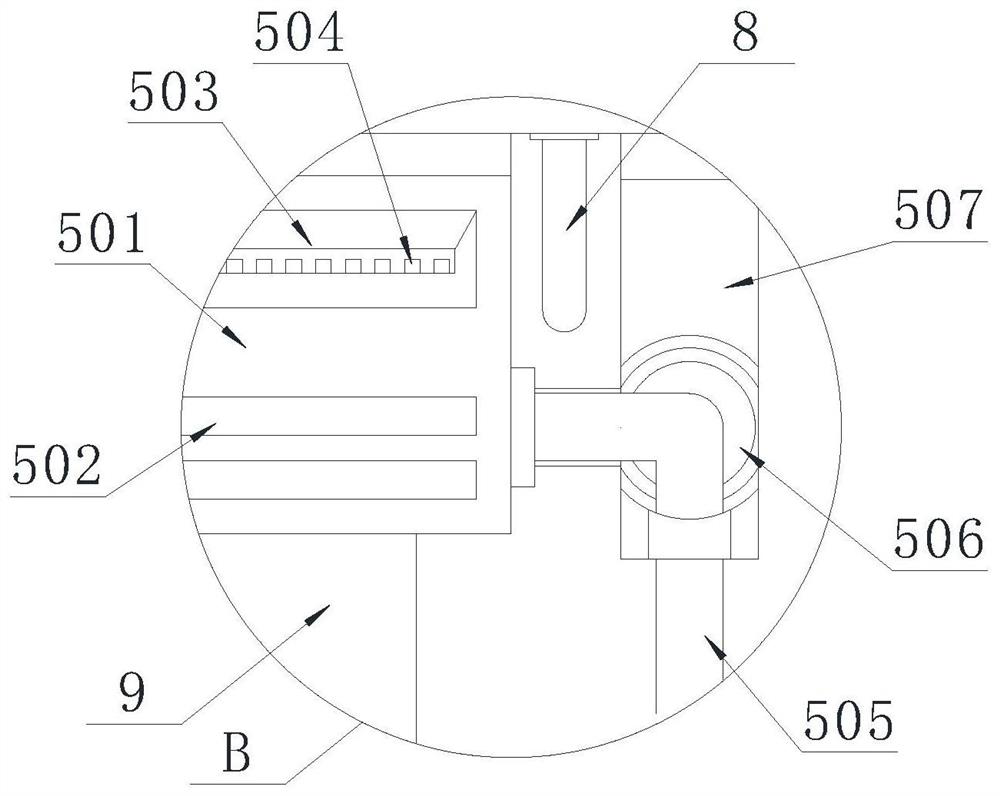

[0041] The implementation is as follows: when the motor assembly 1 needs to be maintained, the rotating rod 405 is driven to rotate by turning the rear handle, and the rotating rod 405 can drive the side stopper 403 to separate from the teeth 402. At this time, the spring 407 can be used Self-elastic force drives one side slide plate 406 to slide in the chute 408, and the movement of the slide plate 406 can extrude one side stop bar 401 to move to the outside. Quickly separate the cover plate 9 from the protective case to facilitate cleaning and maintenance of the motor assembly 1 inside the protective case. At the same time, the spring 407 can squeeze the slider and the limit rod 401 to ensure the assembly stability of the cover plate 9 and avoid motor The vibration of the component 1 during operation causes the cover plate 9 to separate from the protective case, which improves the stability of the working state while ensuring the portability of disassembly and assembly.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com