Dust fall type automatic punching device for carton packaging material production

A technology of packaging materials and punching equipment, which is applied in metal processing, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of inconvenient dust treatment, etc., and achieve the effect of simple structure, convenient use, and enlarged suction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

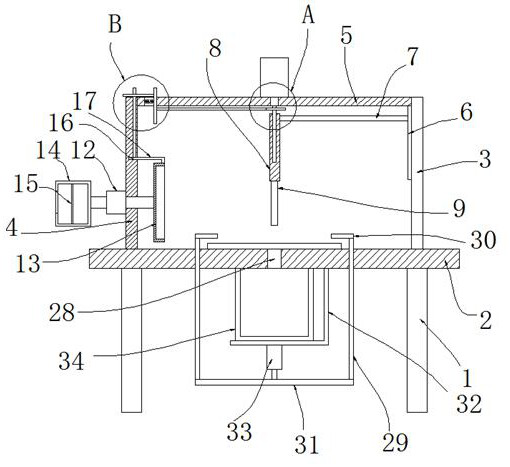

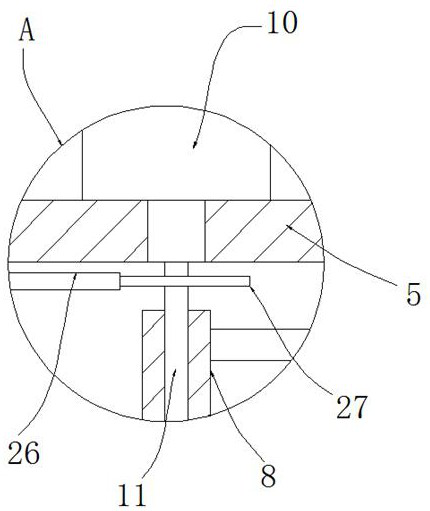

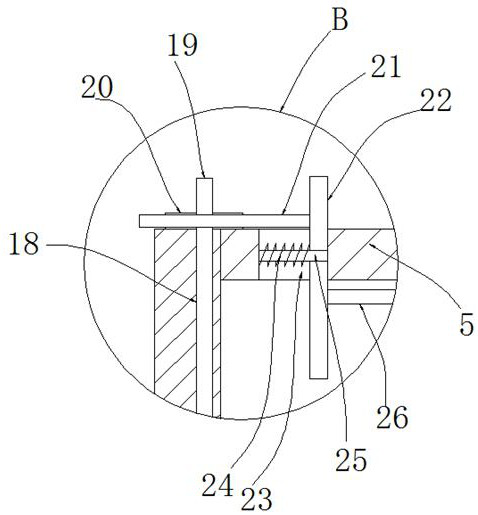

[0023] refer to Figure 1-3 , a kind of automatic punching equipment for the production of dust-reducing carton packaging materials, comprising a punching table 2, a first vertical board 3 and a second vertical board 4 are fixedly installed on the top of the punching table 2, and one of the second vertical boards 4 An air extractor 12 is fixedly installed on the side, and the air inlet of the air extractor 12 is fixedly connected with one end of an air intake hose, and the other end of the air intake hose is fixedly connected with an exhaust hood 13, and the air outlet of the air extractor 12 is fixedly connected One side is set as the filter box 14 of opening, and the filter screen 15 is fixedly installed in the filter box 14, and a side of the second vertical plate 4 is provided with a horizontal groove 16, and an L-shaped rod 17 is installed in the horizontal groove 16, and the L-shaped rod One end of 17 is fixedly connected with exhaust hood 13, offers vertical hole 18 on ...

Embodiment 2

[0030] refer to Figure 1-3 , a kind of automatic punching equipment for the production of dust-reducing carton packaging materials, including a punching table 2, the top of the punching table 2 is fixed with a first vertical board 3 and a second vertical board 4 by bolts, and the second vertical board 4 One side of the air extractor 12 is fixedly installed with bolts, and the air intake of the air extractor 12 is fixedly connected with one end of the intake hose, and the other end of the intake hose is fixedly connected with an exhaust hood 13, and the air extractor 12 The air outlet is fixedly connected with a filter box 14 with an opening on one side, and a filter screen 15 is fixedly installed in the filter box 14 by bolts, and a horizontal groove 16 is provided on one side of the second vertical plate 4, and an L-shaped Bar 17, one end of L-shaped bar 17 is fixedly connected with exhaust cover 13, offers vertical hole 18 on the top inwall of transverse groove 16, and vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com