Walking balance base of wall plastering device

A wall and balance technology, which is applied in the direction of architecture and building construction, can solve problems such as uneven plaster thickness and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

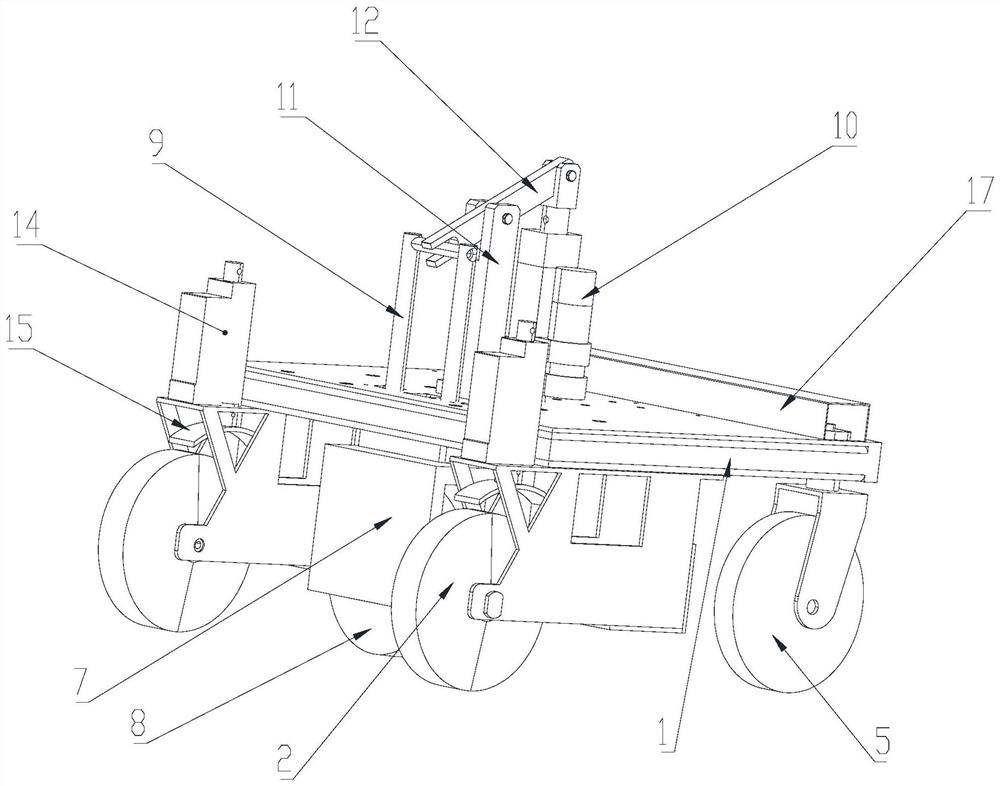

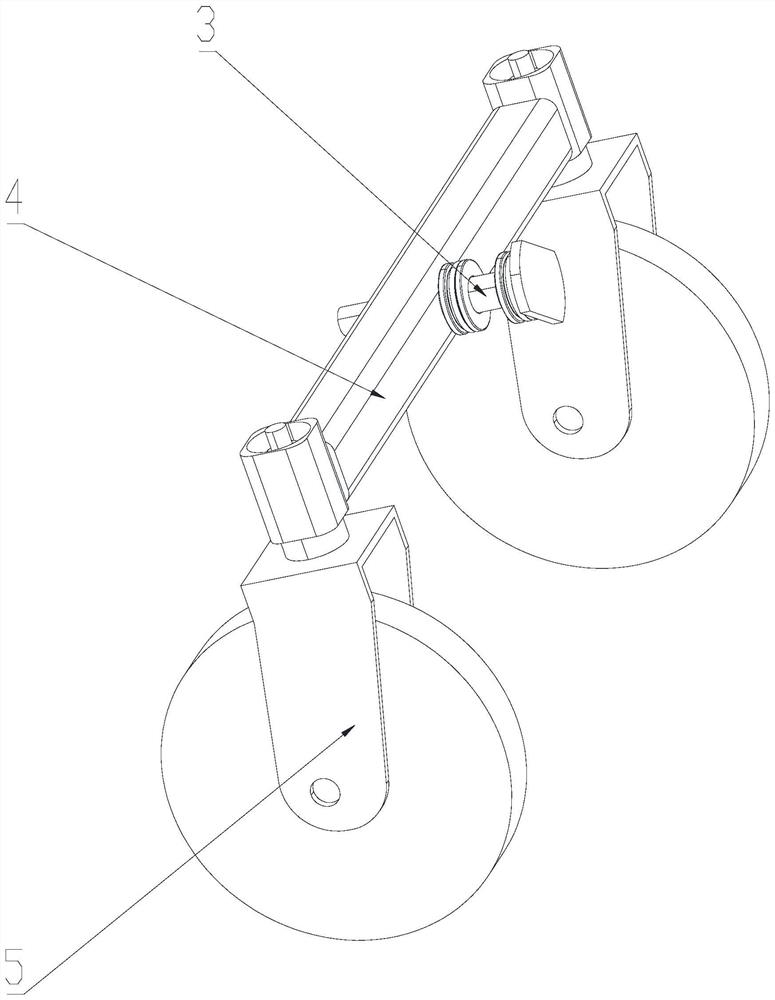

[0031] Such as Figure 1-4 As shown, a walking balance base of a wall plastering device includes a base body 1, front rollers 2 are respectively provided on both sides of the front end of the lower surface of the base body 1, and the rear end of the lower surface of the base body 1 passes through a vertical The transverse axis 3 of the axis of the front roller 2 is rotatably connected with a crossbeam 4, the crossbeam 4 is parallel to the axis of the front roller 2, the transverse axis 3 is located at the geometric center of the crossbeam 4, and the crossbeam The two ends of 4 are provided with universal wheels 5 on the side facing away from the base body 1, and the base body 1 is provided with a beam rotation limiting structure, and the axis of the base body 1 is perpendicular to the front roller 2. A vertical channel 6 that runs through the base body 1 is provided on the center line of the base body 1, and a connecting mechanism is slidably connected in the vertical channel ...

Embodiment 2

[0034] Such as Figure 1-4 As shown, a walking balance base of a wall plastering device includes a base body 1, front rollers 2 are respectively provided on both sides of the front end of the lower surface of the base body 1, and the rear end of the lower surface of the base body 1 passes through a vertical The transverse axis 3 of the axis of the front roller 2 is rotatably connected with a crossbeam 4, the crossbeam 4 is parallel to the axis of the front roller 2, the transverse axis 3 is located at the geometric center of the crossbeam 4, and the crossbeam The two ends of 4 are provided with universal wheels 5 on the side facing away from the base body 1, and the base body 1 is provided with a beam 4 rotation limit structure, and the base body 1 is vertical to the front roller 2. The center line of the axis is provided with a vertical channel 6 that runs through the base body 1, and a connecting mechanism is slidably connected in the vertical channel 6, and the lower end of...

Embodiment 3

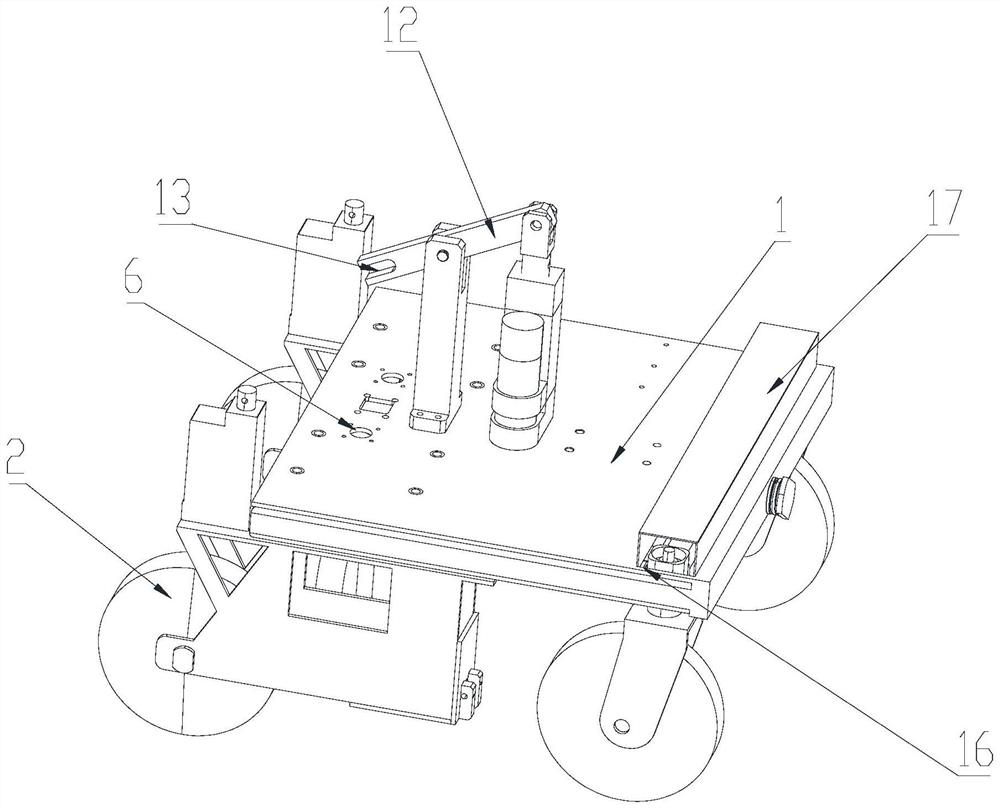

[0046] Such as Figure 5 As shown, a walking balance base of a wall plastering device includes a base body 1, front rollers 2 are respectively provided on both sides of the front end of the lower surface of the base body 1, and the rear end of the lower surface of the base body 1 passes through a vertical The transverse axis 3 of the axis of the front roller 2 is rotatably connected with a crossbeam 4, the crossbeam 4 is parallel to the axis of the front roller 2, the transverse axis 3 is located at the geometric center of the crossbeam 4, and the crossbeam The two ends of 4 are provided with universal wheels 5 on the side facing away from the base body 1, and the base body 1 is provided with a beam 4 rotation limit structure, and the base body 1 is vertical to the front roller 2. The center line of the axis is provided with a vertical channel 6 that runs through the base body 1, and a connecting mechanism is slidably connected in the vertical channel 6, and the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com