Tray arranging mechanism used after rubber tube sleeving of capacitor

A technology of capacitors and rubber hoses, which is applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve the problems of capacitor pins colliding with each other, easy to puncture defective hoses, etc., and achieve the effect of fast recognition and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

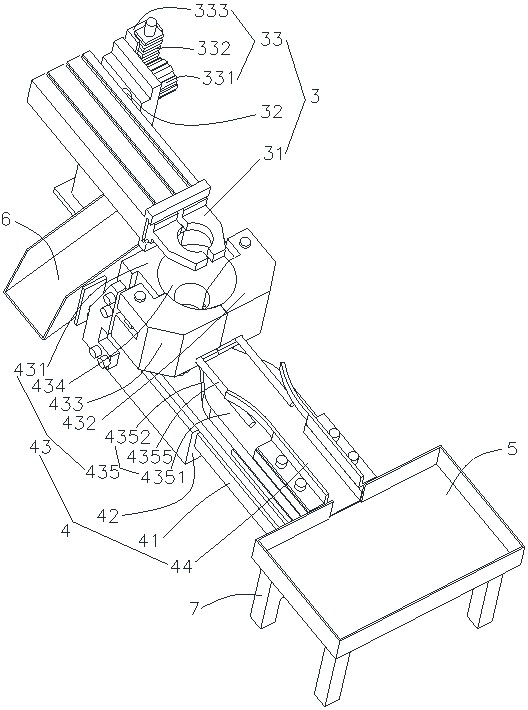

[0027] Such as Figure 3~5As shown, a disk arrangement mechanism behind a capacitor sleeve rubber hose includes a grasping device 3, a pushing device 4 and a good product disk 5 arranged in sequence; the pushing device includes a linear guide rail 41, a slider 42 and a pushing clamp assembly 43, the The push clip assembly 43 includes a clip body 431, a left clip 432 and a right clip 433, and the left clip 432 and the right clip 433 are all rotatably arranged on the clip body 431, and the clip body 431, the left clip 432 and the right chuck 433 surround and pass through a clamping cavity 434 along the circumferential direction, the clamping cavity 434 is opened in the vertical direction, and the left clamp 432 and the right clamp 433 are driven to rotate by the clamp driver 435, when When the left chuck 432 and the right chuck 433 rotate close to each other, the clamping cavity 434 closes the clamping capacitor; when the left clamp 432 and the right clamp 433 rotate away from e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com