Automatic detection instrument for size of synchronous pulley of automobile steering device

A technology of automobile steering gear and synchronous pulley, applied in sorting and other directions, can solve the problems of batch processing of synchronous pulley, misleading data, affecting orderly production, and less detection of synchronous pulley, etc., to achieve fast and effective batch measurement, high efficiency The effect of completing the test work and high-precision automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] The present invention will be described in detail below with reference to the accompanying drawings and specific examples.

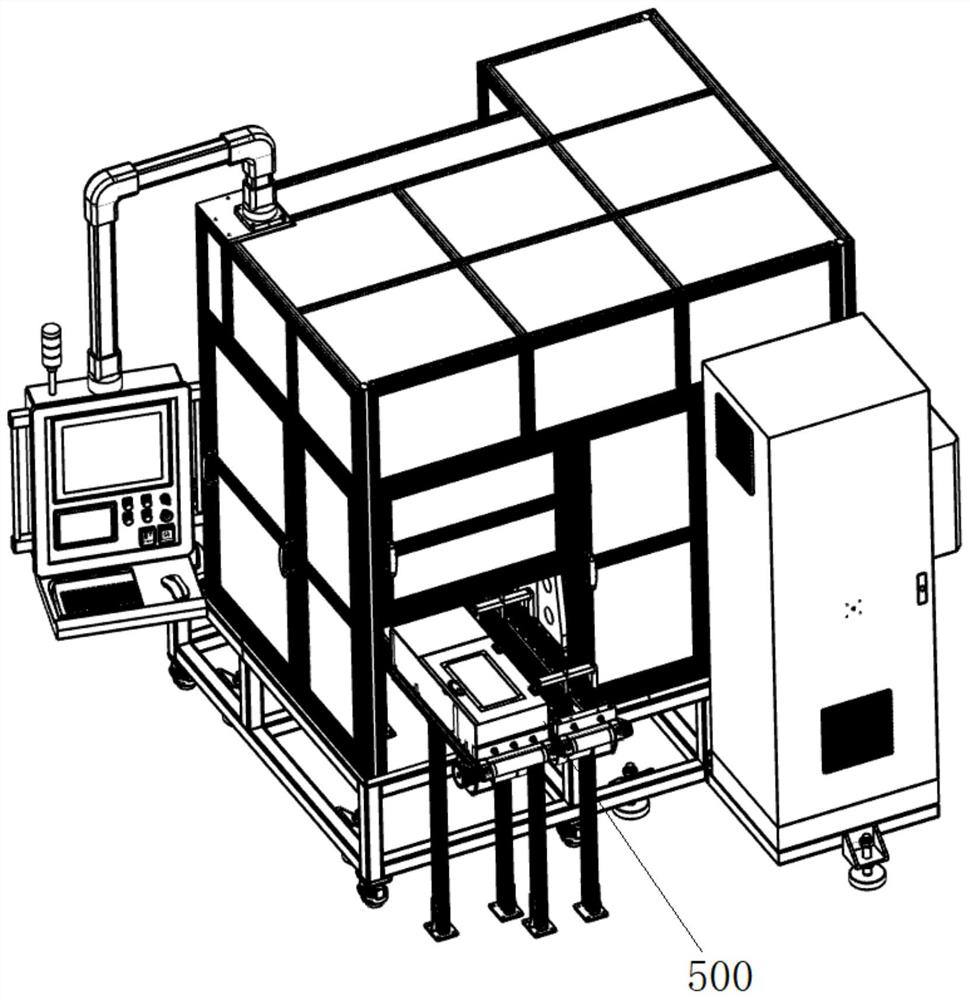

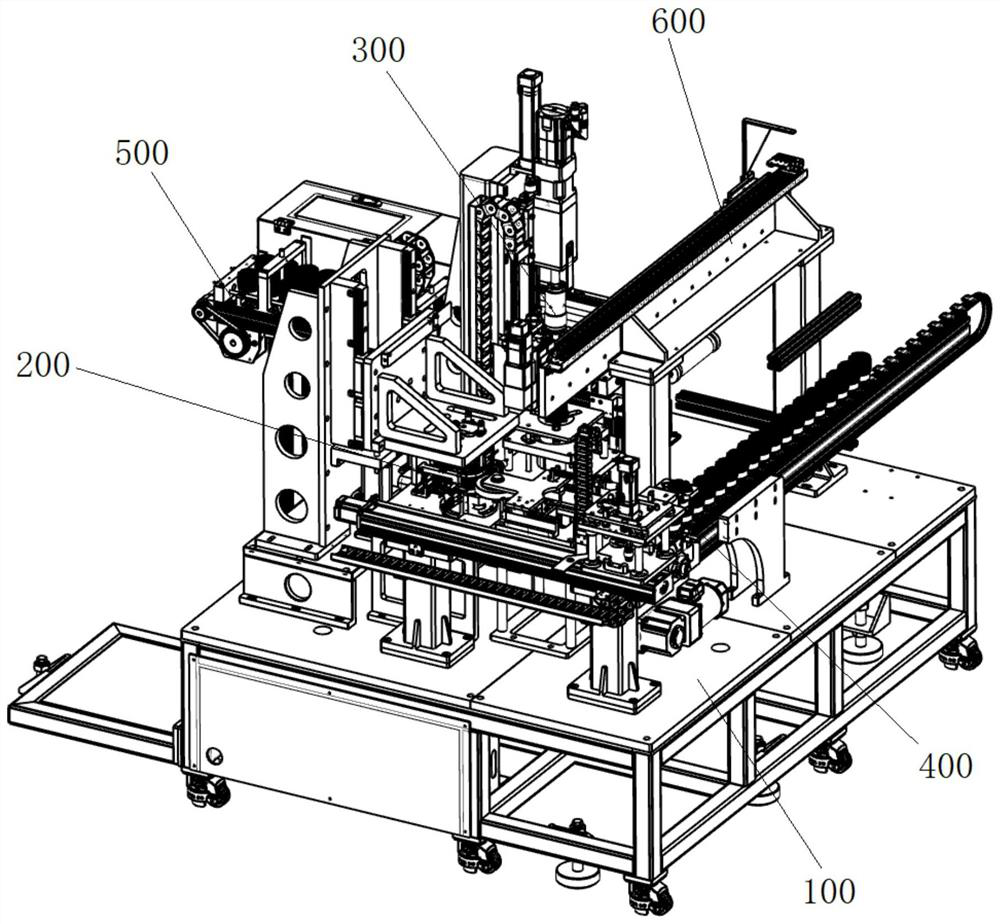

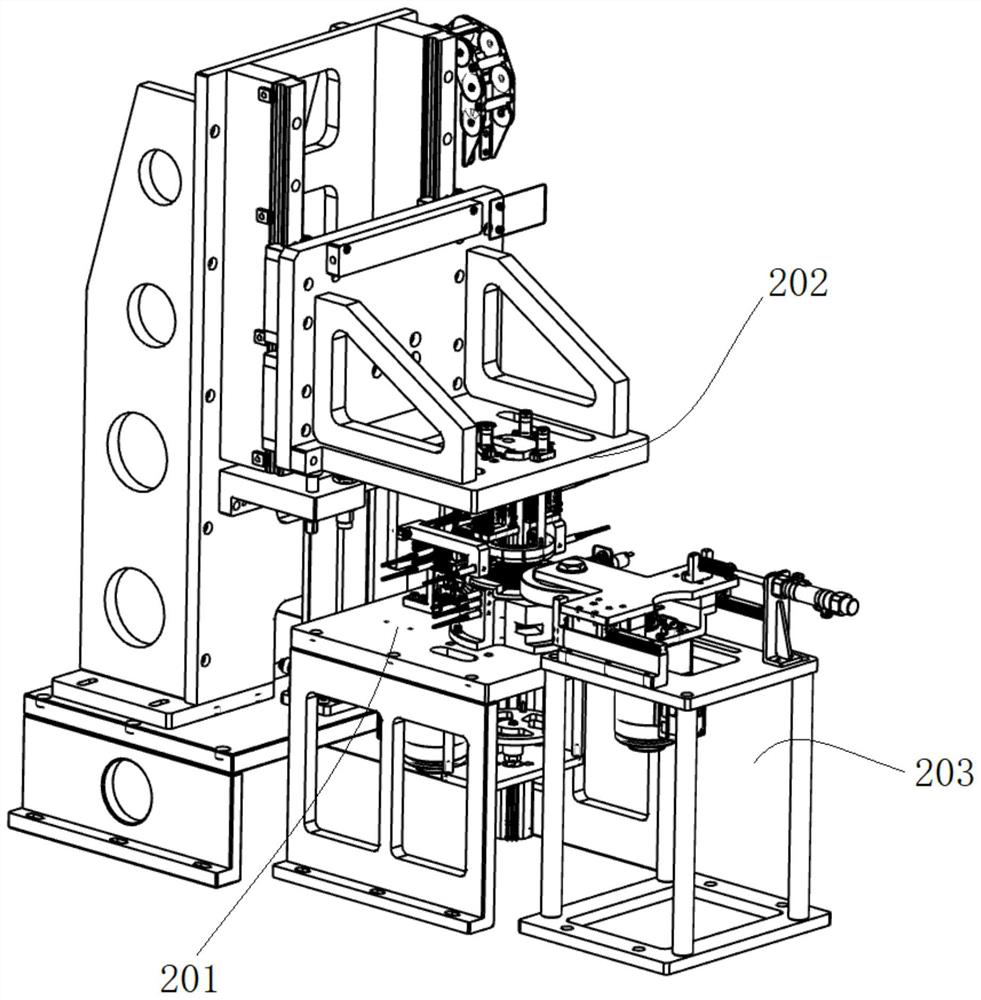

[0044] like Figure 1 , 2 An automotive steering gear synchronous pulley size automatic detection instrument, including the base 100 and on the base 100: size measuring station 200 for the size detection of the workpiece; thread measurement station 300 for test The thread detection of the workpiece; the workpiece delivery mechanism 400, is used to deliver the sub-test of the upper step to the corresponding station; the method 500 is used to detect the conveyance of the test workpiece; the grip mechanism 600 for use The workpiece is sequentially transferred from the conveying mechanism to the size measuring station 200, the thread measurement station 300 and the lower body body 500, the upper part of the base 100 is provided with a shield, and the detection instrument also has a SPC analysis system and an electrical control system. The cabinet, the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com