Rapid-clamp driver

A drive, fast technology, applied in the direction of workpiece clamping device, sorting, manufacturing tools, etc., can solve the problems of long time, unsatisfactory sorting machine, complex structure, etc., to achieve convenient operation, shorten auxiliary time, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

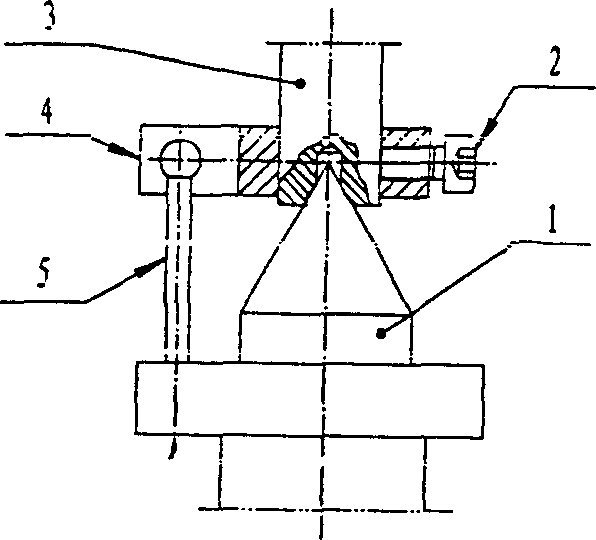

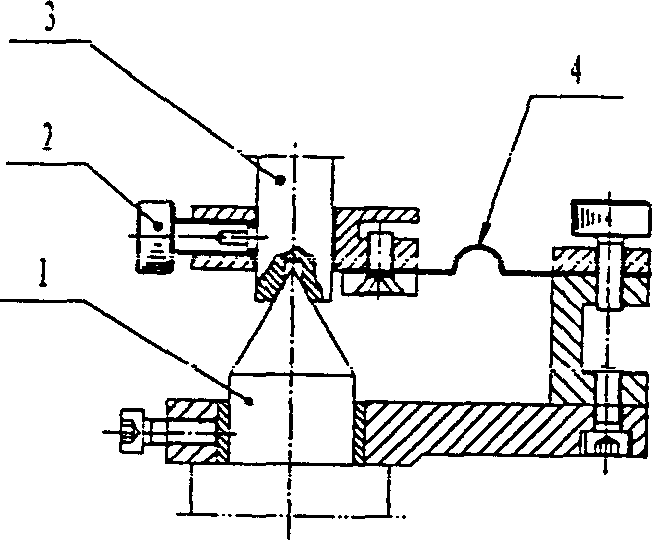

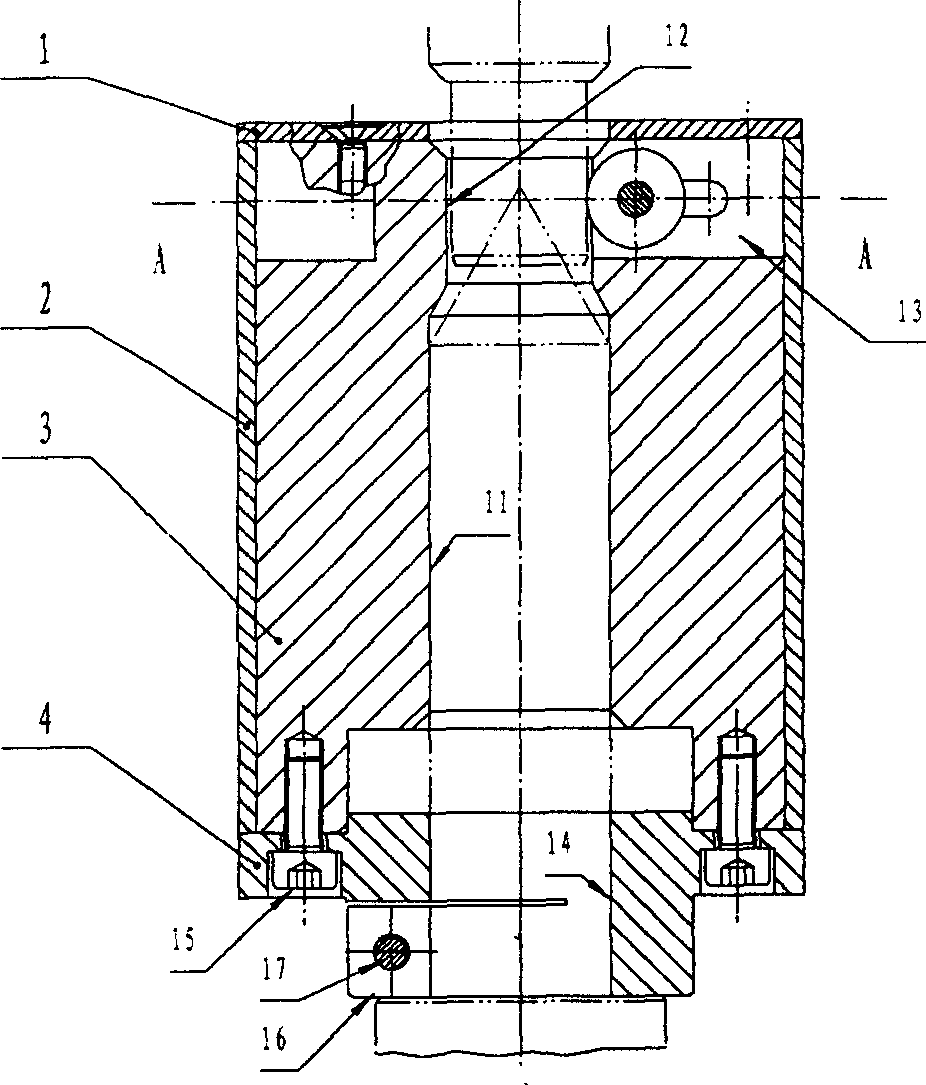

[0018] The present invention is made up of parts 1-8, and the fixed seat 4 and the driver seat 3 are fastened together by M4 screws. And fasten part 4 coaxially with the main shaft of the sorting machine with M4 screws. The clamping mechanism composed of bearing 5 (sliding bearing or deep groove ball bearing, pin shaft 6, and washer 7) is installed on the driver seat; the elastic stopper 8 is used to make the bearing 5 tightly pressed against the shaft of the gear shaft under test On the neck. When the journal of the shaft gear is put into the inner hole of the driver, the top center quickly pushes the top hole of the journal of the shaft gear into the top of the main shaft of the instrument. When the main shaft rotates, the driver rotates synchronously with it. Since the bearing 5 is tight The ground is pressed on the journal of the measured shaft gear, so that the shaft gear also rotates synchronously with the main shaft. The inner hole of the drive seat 3 has chamfers, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com