A multi-station multi-parameter high-precision measurement method and device for light curtain type shaft parts

A technology for shaft parts and measuring devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of testing and testing equipment with single functions and low detection efficiency, so as to expand the measurement range, improve the measurement cycle, and improve the measurement efficiency. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific examples, and methods not described in detail in the present invention are all prior art.

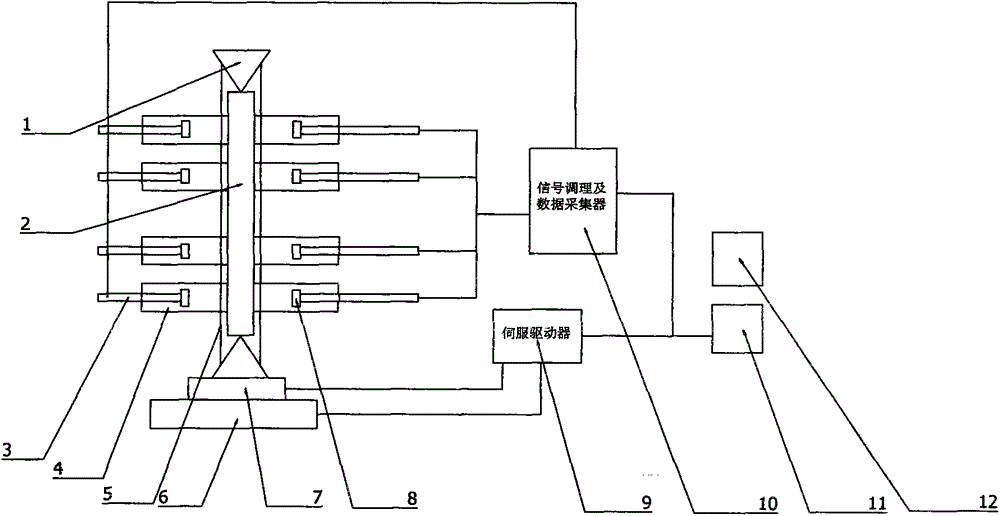

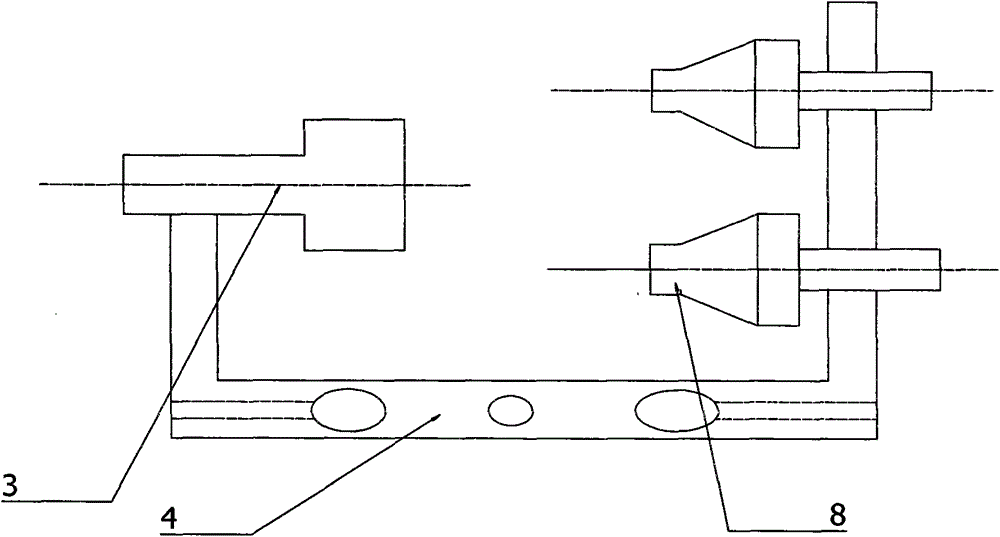

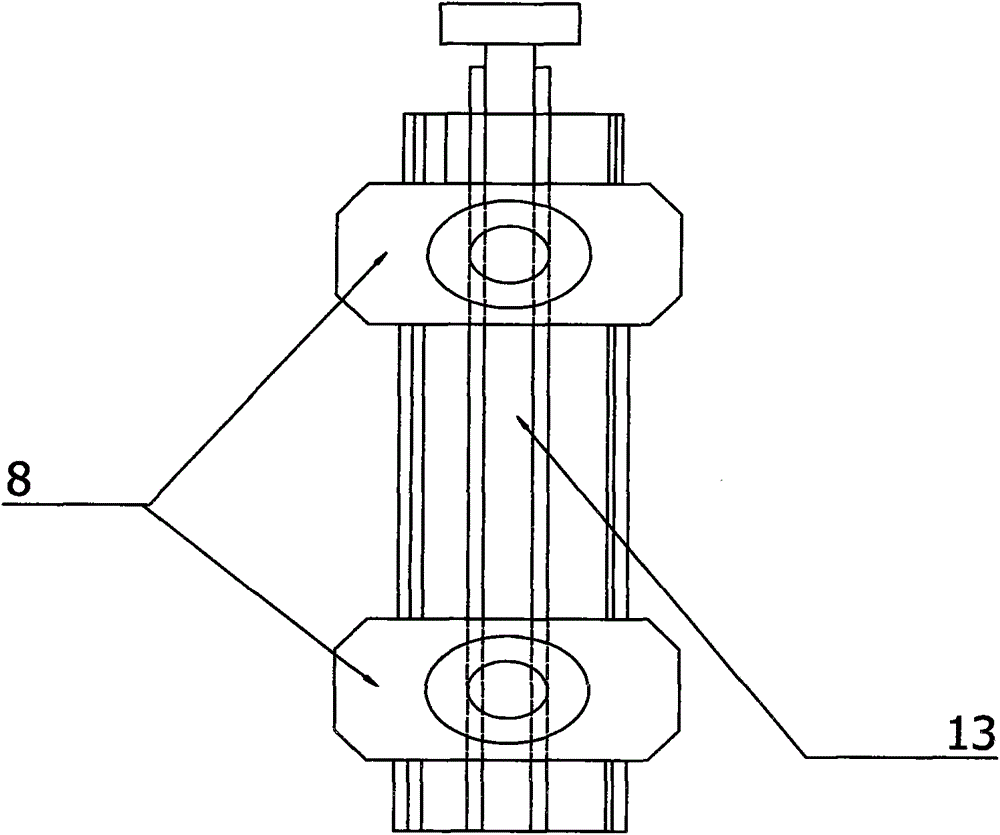

[0014] Such as figure 1 As shown, the multi-station, multi-parameter and high-precision measuring device for light curtain type shaft parts includes an electromechanical body and four measuring head devices, such as figure 2 As shown, the probe device includes a support base 4 with slide rails, a slit LED parallel light source 3 and two linear array CCD cameras 8. The slit parallel LED light source 3 changes in sinusoidal regular brightness under computer control, and the slit LED parallel light source 3. The green parallel light with low divergence angle is generated, and the upper and lower edges of the light spot are blocked by the shaft part 2 to be measured and collected by two linear array CCD cameras 8. The irradiation direction of the slit LED parallel light source 3 is the same as that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com