Sound dampening member for electric-powered vehicles

A technology for electric vehicles and components, applied in electric vehicles, vehicle components, electric power devices, etc., can solve problems such as sound residue, and achieve the effect of preventing the generation of wind noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0321]

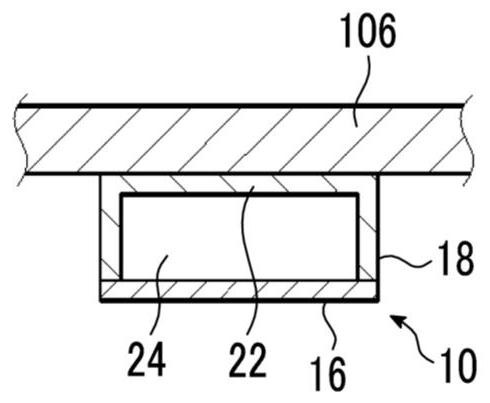

[0322] An acrylic plate (manufactured by Hikari Co., Ltd.) with a thickness of 3 mm was prepared, and a frame body having 6×11 openings of 20 mm×20 mm was produced. Processing is performed using a laser cutter. The overall size is set to 300mm×180mm.

[0323] As the back panel, an acrylic plate with a thickness of 2mm was processed to a size of 300mm×180mm, and it was attached to one surface of the frame. Mounting was performed using double-sided tape (Genbano Chikara manufactured by ASKUL Corporation).

[0324] As a film member, a PET film (Lumirror manufactured by TORAY INDUSTRIES, INC.) having a thickness of 50 μm was cut into a size of 300 mm×180 mm. Use double-sided tape to attach the film-like component to the other side of the frame.

[0325] In this way, a film-like member with a thickness of 50 μm constitutes a film vibrating portion with a size of 20 mm×20 mm, and 6×11 film-type resonant structures with a rear surface distance of 3 mm are arranged.

[...

Embodiment 2

[0350] The thickness of the back space (that is, the thickness of the acrylic plate) is set to 5 mm, the size of the opening of the frame is set to 30 mm × 30 mm, the thickness of the film-like member (PET film) is set to 100 μm, and 4 In the same manner as in Example 1, except for the structure of ×8, a membrane-type resonant structure was produced, and the amount of attenuation was measured in the same manner as in Example 1.

[0351] The film-type resonant structure of Example 2 has a sound absorption peak around 2 kHz.

[0352] show the result in Figure 29 .

[0353] Depend on Figure 29 It can be seen that, compared with Comparative Example 1, the amount of silencing in Example 2 is larger, and a maximum amount of silencing of 10.5 dB can be obtained.

Embodiment 3

[0355] A film-type resonant structure was produced in the same manner as in Example 1 except that the thickness of the back space (that is, the thickness of the acrylic plate) was 2 mm, and 6×11 pieces were arranged. The amount of attenuation was measured in the same manner as in Example 1.

[0356] The film-type resonant structure of Example 3 has a sound absorption peak around 4.5 kHz.

[0357] show the result in Figure 30 .

[0358] Depend on Figure 30 It can be seen that the amount of attenuation in Example 3 is larger than in Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com