Salt protection flux-free brazing method and brazing device

A brazing method and flux-free technology, applied in electric heating devices, auxiliary devices, welding equipment, etc., to achieve the effects of easy cleaning, good protection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

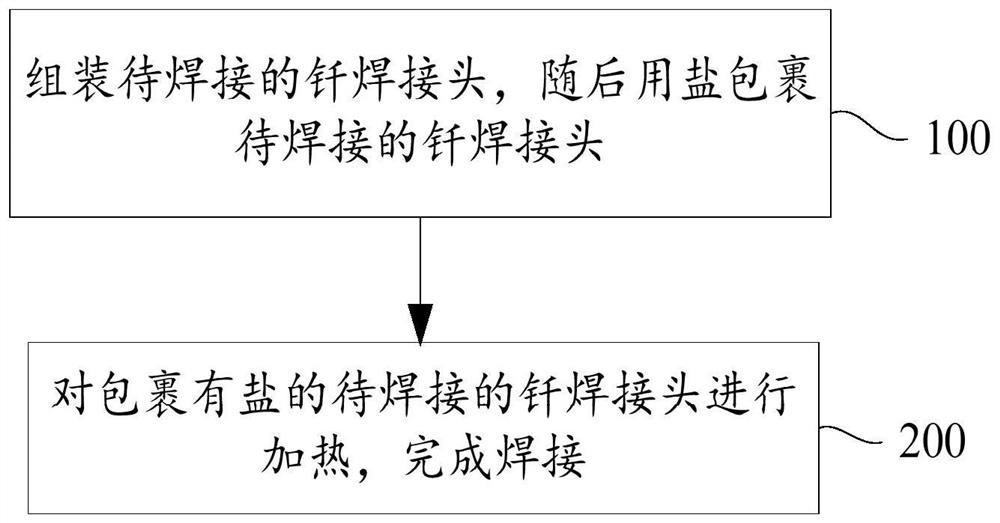

[0035] see figure 1 As shown, the embodiments of the present application provide a kind of salt-protected flux-free brazing method, comprising the steps of:

[0036] Step 100, assembling the brazing joint to be welded, and then wrapping the brazing joint to be welded with salt 5;

[0037] Note: the assembled brazing joint to be welded has a structure in which a solder 4 is sandwiched between the first piece to be welded 2 and the second piece to be welded 3 .

[0038] Step 200, heating the to-be-welded brazing joint wrapped with the salt 5 to complete the welding.

[0039] During the brazing process, part of the salt 5 close to the welding material melts, effectively isolating the air and reducing the oxidation of the brazed joint, and after the welding is completed, the salt 5 solidifies during the cooling process, which can also protect the brazed joint role.

[0040] After the above analysis, it can be known that among various salt-protected flux-free brazing methods, th...

Embodiment 2

[0053] Embodiments of the present application also provide a brazing device, which is applied to the salt-protected flux-free brazing method described in any of the above embodiments, and thus has all the beneficial technical effects of the method.

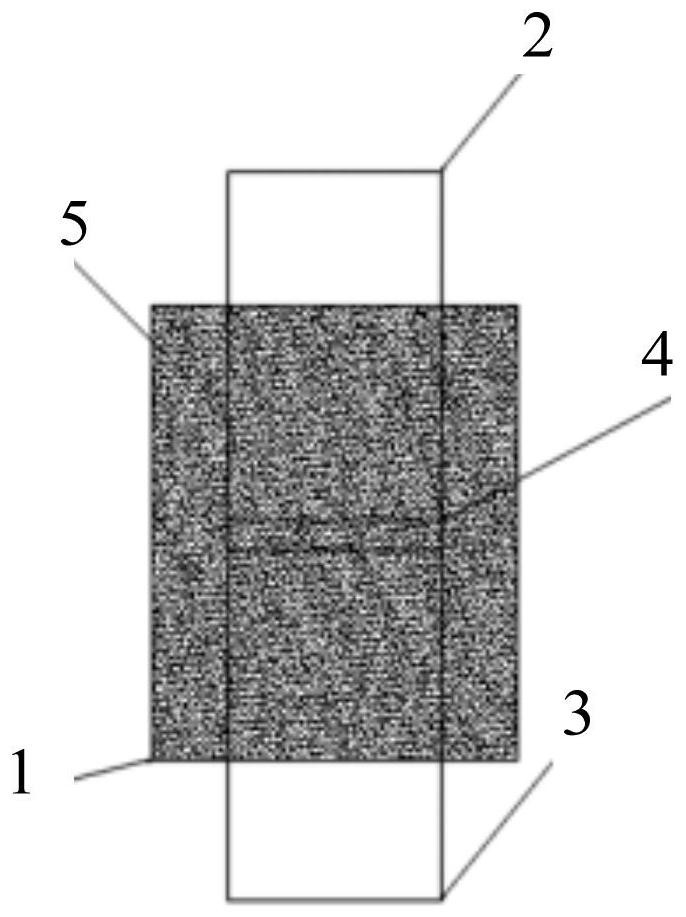

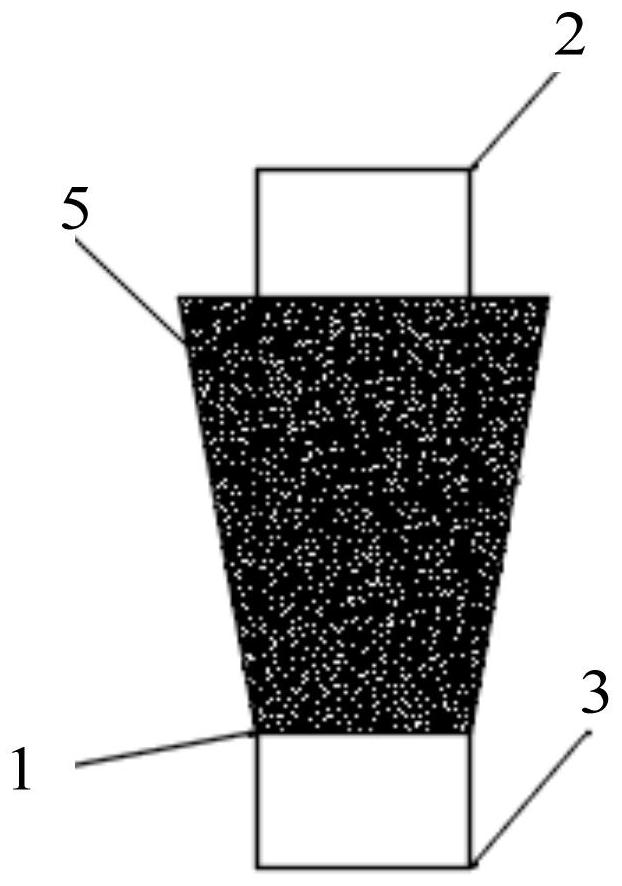

[0054] In this embodiment, preferably, as figure 2 with image 3 As shown, the brazing device includes a carrying member 1 and a welding heating mechanism. The interior of the carrying member 1 is hollow and its two ends are formed with openings. The inside of the carrying member 1 is used to carry the brazing joint to be welded wrapped with salt 5, It should be noted here that the entire end portion may be completely opened, or part of the entire end portion may be formed with openings, that is, there is a partially shielded structure, which can be selected according to actual needs.

[0055] The welding heating mechanism is used to heat the brazing joint to be welded wrapped with salt 5 placed in its bearing member 1, wherein,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com