An air compressor unloading device and a solenoid valve using the unloading device

A technology of unloading device and air compressor, which is applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc., which can solve the problems of reducing the service life of air compressors, increasing the use cost, and large starting load, etc., to achieve improved Long service life, prevention of starting with load, good exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

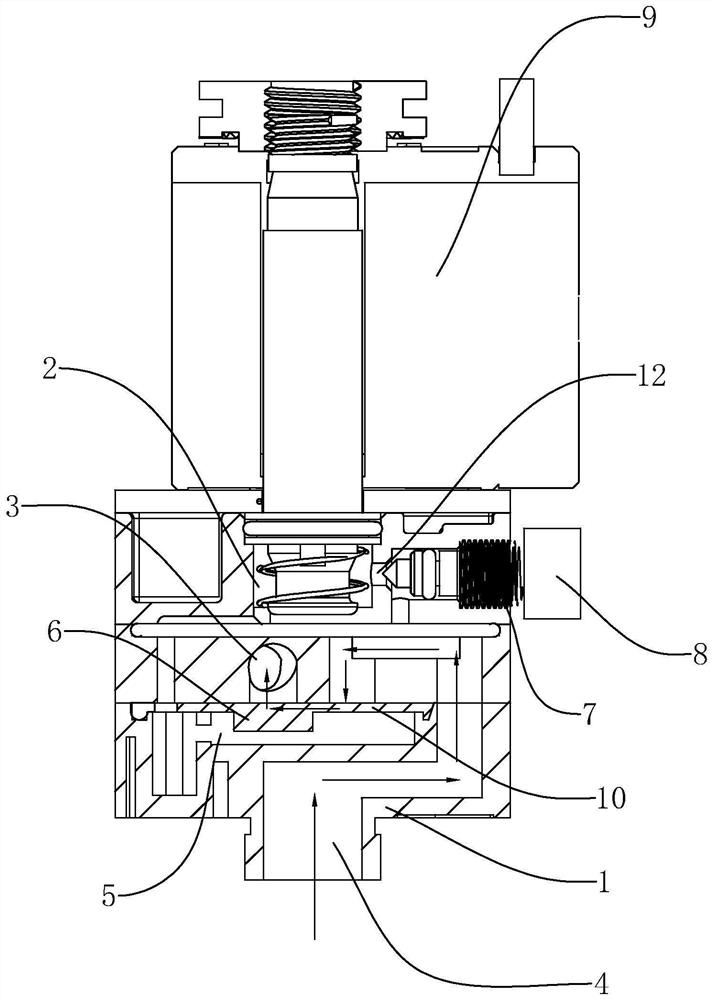

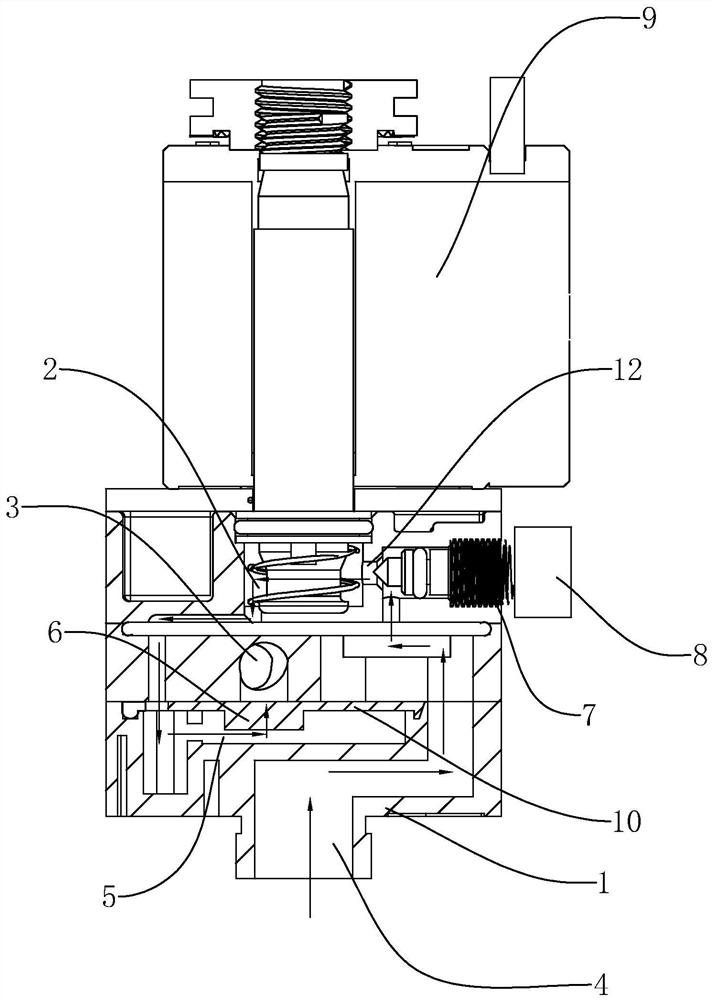

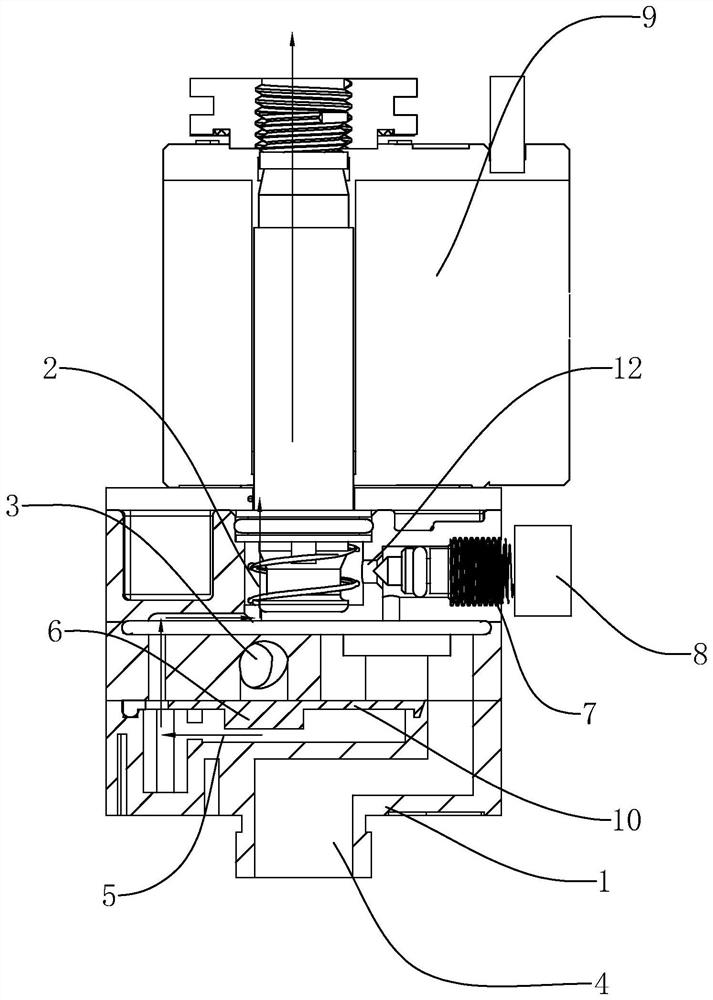

[0021] as Figure 1-6 As shown, an air compressor unloading device, comprising a base 1, the base 1 is provided with a capacitive cavity 2 may be compatible with the solenoid valve 9, the base 1 is provided with at least one discharge hole 3 and an inlet air channel 4 connected to the exhaust pipe, the inlet air channel 4 is connected to at least one discharge hole 3 to form a first discharge channel (the first discharge channel of the air path may be seen Figure 1 As shown by the arrow), the base 1 is further built with a connecting chamber 5, the connecting chamber 5 is connected to the capacitive cavity 2, the discharge hole 3 and the inlet air channel 4, the connecting chamber 5 is built with a gasket 6 that can conduct or block the first discharge channel, the side of the gasket 6 is provided with a pressure portion 10 may be separated from the inlet air channel 5, the pressure portion 10 is provided with a pressure surface in contact with the inlet air channel.

[0022] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com