A kind of in situ growth SiC nanowire modified SiC f Preparation method and application of /sic ceramic matrix composite material

An in-situ growth and composite material technology, applied in the field of ceramic matrix composite material preparation, can solve the problems of reduced material performance, low preparation efficiency, and ineffective reinforcement and toughening of composite materials, etc., to achieve improved crushing performance and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

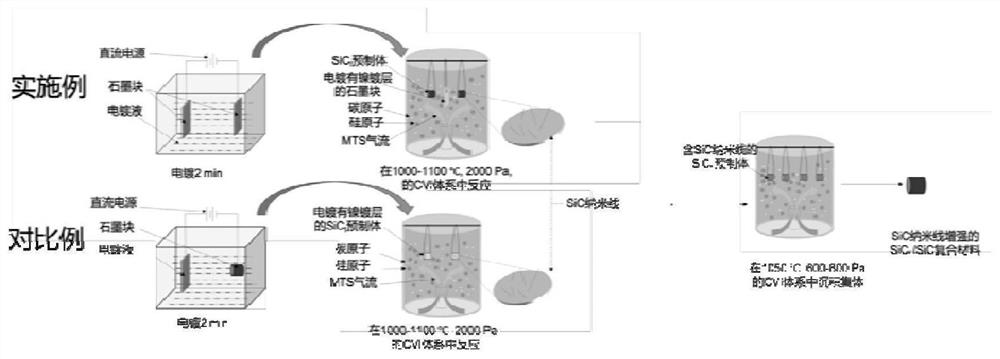

Method used

Image

Examples

Embodiment 1

[0039] step 1:

[0040] 1 Polish the graphite sheet with sandpaper, ultrasonically clean it for 10 minutes and then dry it. Use wires to connect the graphite electrodes to both ends of the 32V DC power supply, respectively as the cathode and anode of the electrolytic cell, soaked in NiSO 4 (16.25g / L)+NiCl 2 (2.5g / L) + boric acid (2.5g / L) + sodium lauryl sulfate (0.0125g / L)) electroplating solution, turn on the power, set the current intensity of 1A, and the electroplating time is 2min.

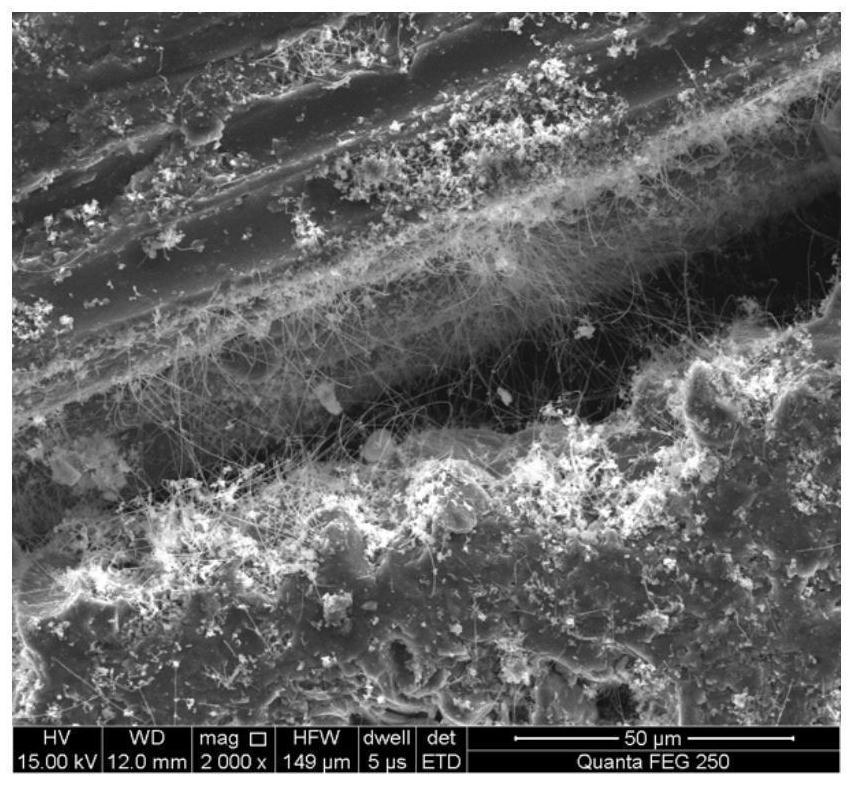

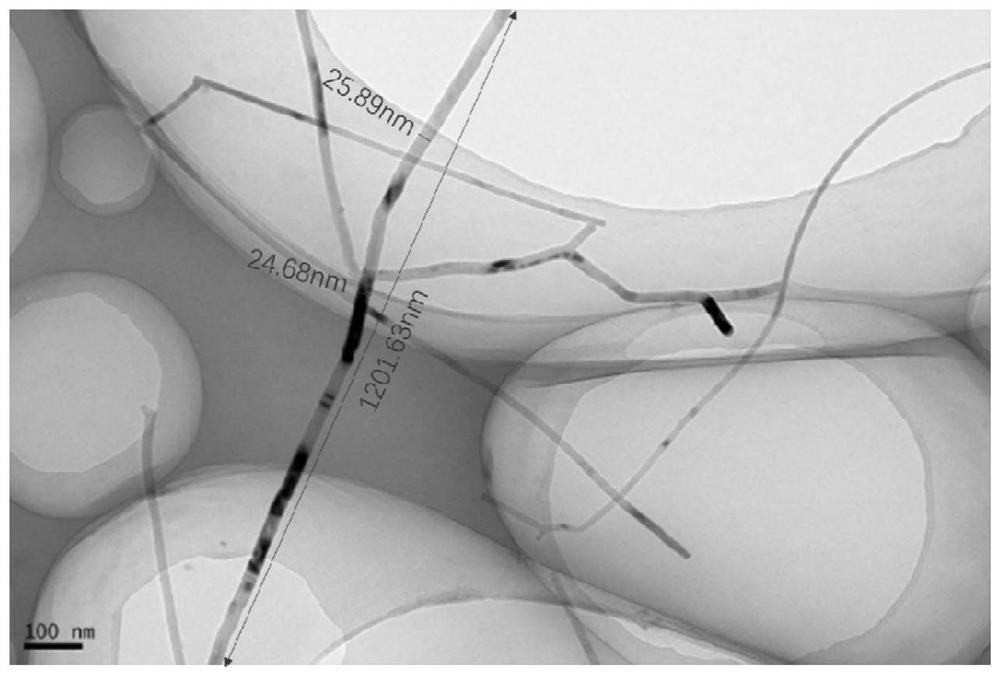

[0041] 2 Place the electroplated graphite sheet and the SiC fiber prefabricated cladding tube together in a chemical vapor deposition furnace (see Figure 1), turn on the vacuum pump to evacuate to below 2000Pa, raise the temperature to 300°C at a rate of 5°C / min and keep it for 1h. At the same time, 400ml / min of H 2 Discharge impurities and clean the furnace. After the furnace cleaning is completed, heat the trichloromethylsilane water bath to 36°C, and at the same time continue to raise t...

Embodiment 2

[0050] step 1:

[0051] 1 Polish the graphite sheet with sandpaper, ultrasonically clean it for 10 minutes and then dry it. Use wires to connect the graphite electrodes to both ends of the 32V DC power supply, respectively as the cathode and anode of the electrolytic cell, soaked in NiSO 4 (16.25 g / L)+NiCl 2 (2.5g / L) + boric acid (2.5g / L) + sodium lauryl sulfate (0.0125g / L)) electroplating solution, turn on the power, set the current intensity of 1A, and the electroplating time is 2min.

[0052] 2 Place the electroplated graphite sheet and the SiC fiber prefabricated cladding tube together in a chemical vapor deposition furnace, turn on the vacuum pump to evacuate to below 2000Pa, raise the temperature to 300°C at a rate of 5°C / min and keep it warm for 1h, and at the same time inject 400ml / min H 2 , discharge impurities and clean the furnace. After the furnace cleaning is completed, heat the trichloromethylsilane water bath to 36°C, and continue to raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com