Inner container and transport and storage container for liquid having same

A technology for internal containers and liquids, applied in the direction of transportation and packaging, containers, large containers, etc., can solve the problems of unfavorable and unfavorable large-volume design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

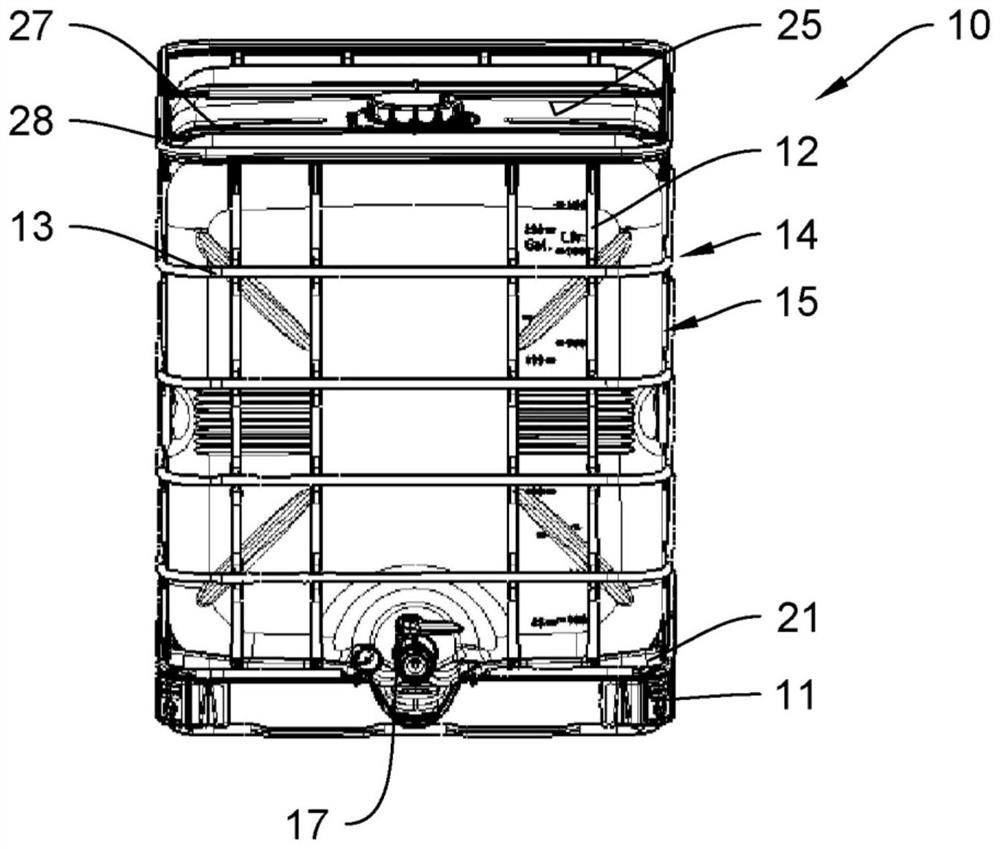

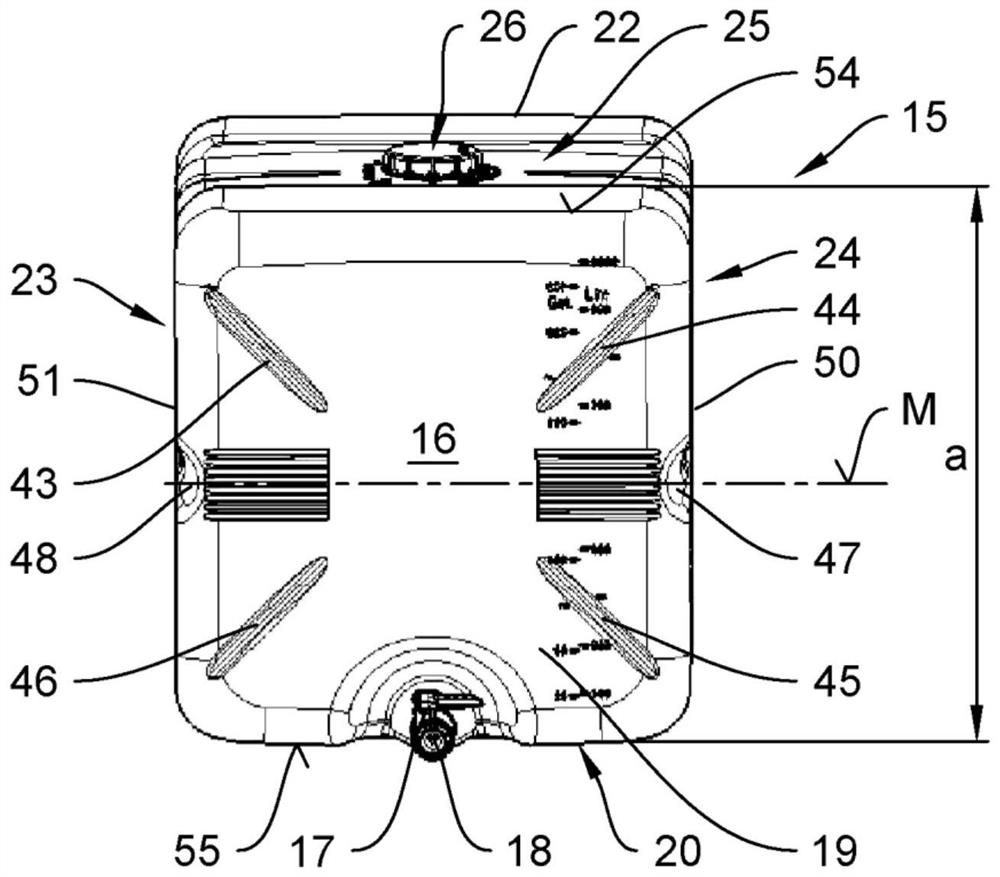

[0038] figure 1 Shown is a transport and storage pallet 10 having as an essential part a transport pallet 11 on which is arranged an outer sheath 14 realized with vertical bars 12 and horizontal Cage for rod 13 . An inner container 15 made of plastic is arranged on the transport pallet 11 inside the outer sheath 14, the inner container 15 having an outlet receptacle 18 provided with an outlet fitting 17 in the front wall 16 on the front side, in particular like figure 2 shown in .

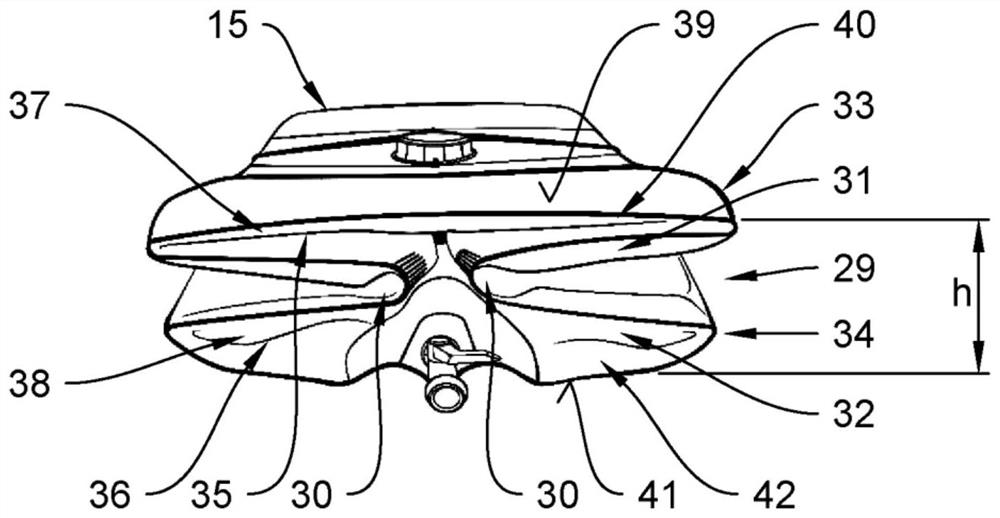

[0039]The outlet receptacle 18 is positioned in the lower wall section 19 of the front wall 16 in the region of the transition to the bottom wall 20 of the inner container 15 which is arranged on the pallet floor 21 of the transport pallet 11 . The bottom wall 20 connects the front wall 16 to a rear wall 22 formed on the rear side of the inner container 15 , and connects the opposite two side walls 23 and 24 . A top wall 25 provided with a filling opening 26 is formed opposite to the bottom wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com