Self-compensation type wire clamp installation system for J-shaped wire clamp

An installation system and self-compensation technology, which is applied in the direction of cable installation, cable installation device, equipment for removing/armouring cables, etc., can solve the problems of increased design difficulty, dislocation lock, complex structure, etc., and achieve reliable and stable use, Effect of reliable clamping and ensuring positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

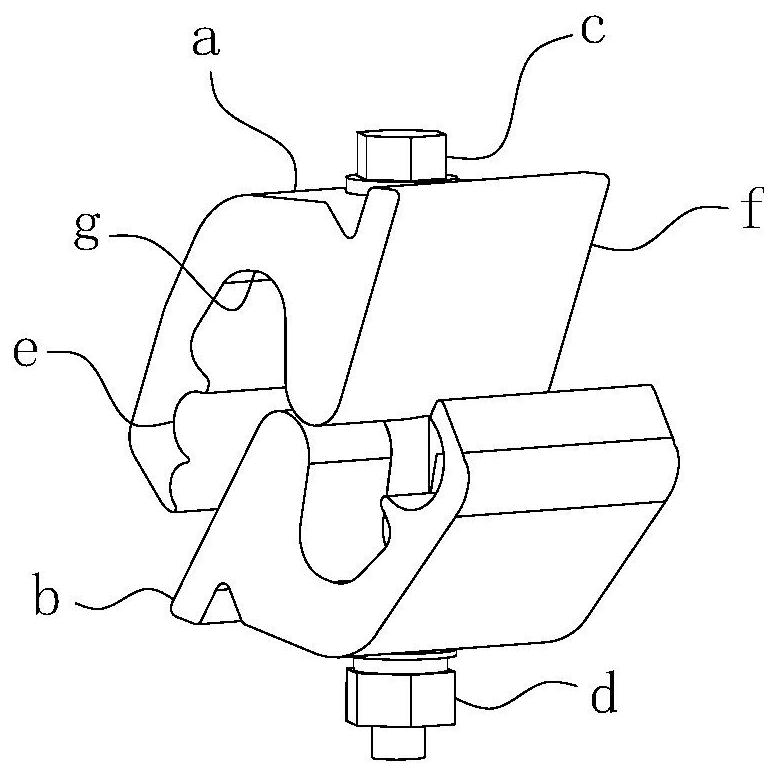

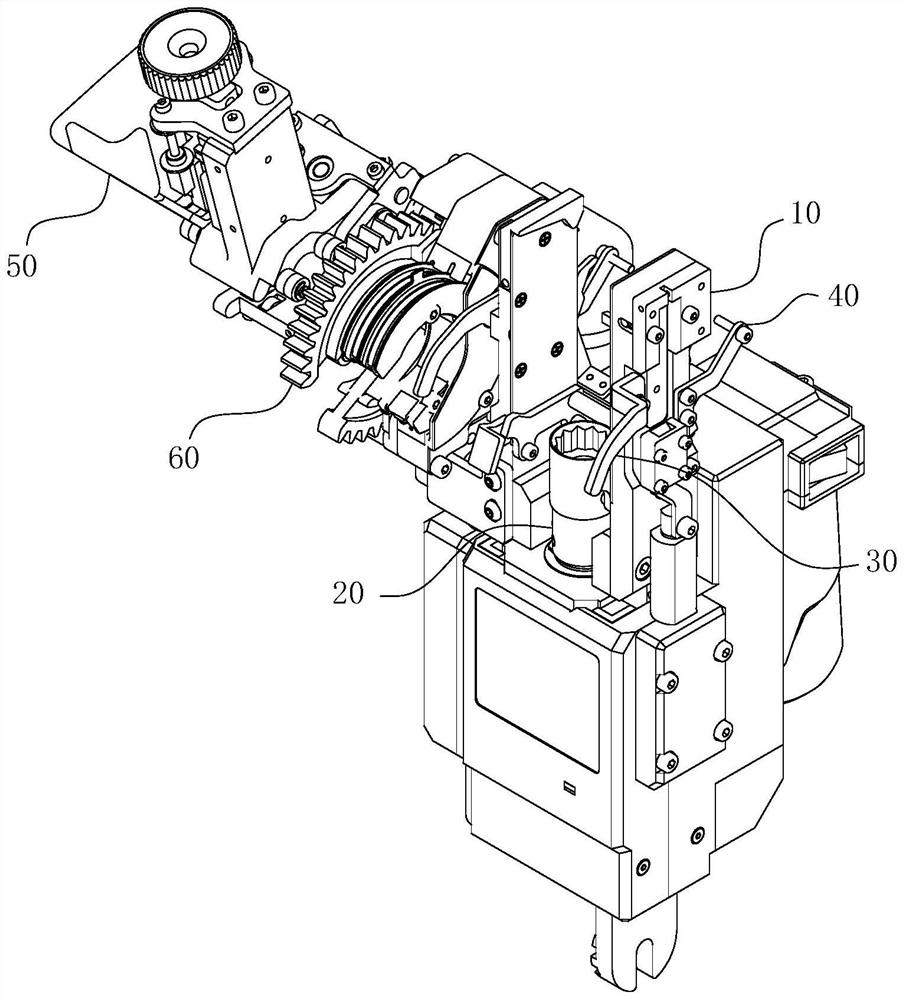

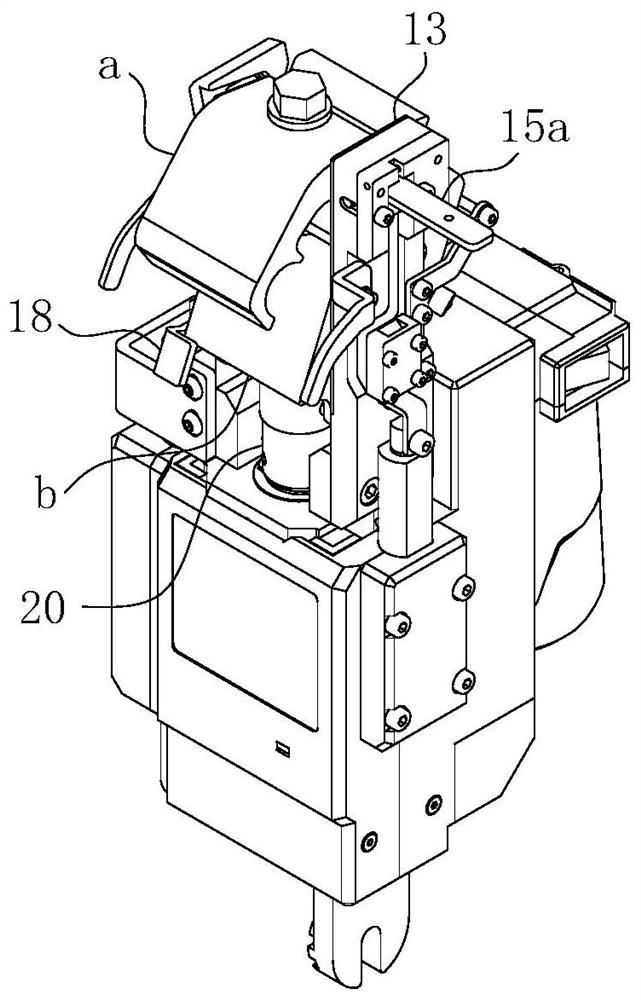

[0064] For ease of understanding, combined here Figure 1-17 , taking the installation and construction of traditional J-type wire clips (hereinafter referred to as wire clips) as an example, the concrete structure and working method of the present invention are further described as follows:

[0065] The present invention can be used in remote control equipment such as robots; during actual assembly, the present invention can be fixed on the mechanical arm. At this time, since the main line is fixed as a reference object, the present invention can be lifted by the mechanical arm to complete the relative main line. The hook-type parallel ditch operation.

[0066] During the actual work of the present invention, its concrete structure is as Figure 2-17 As shown, it is divided into a stripper and a clamp installer located behind the stripper; when it is necessary to operate figure 2 In the structure shown, the cable is first clamped and stripped by the stripper, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com