Water quality monitoring equipment

A technology for water quality monitoring and equipment, applied in testing water, measuring devices, material inspection products, etc., can solve problems such as increased power loss, loosening of bolts, and easy shaking of support rods, and achieves improved service life, good dryness, and reduced The effect of loss of electrical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

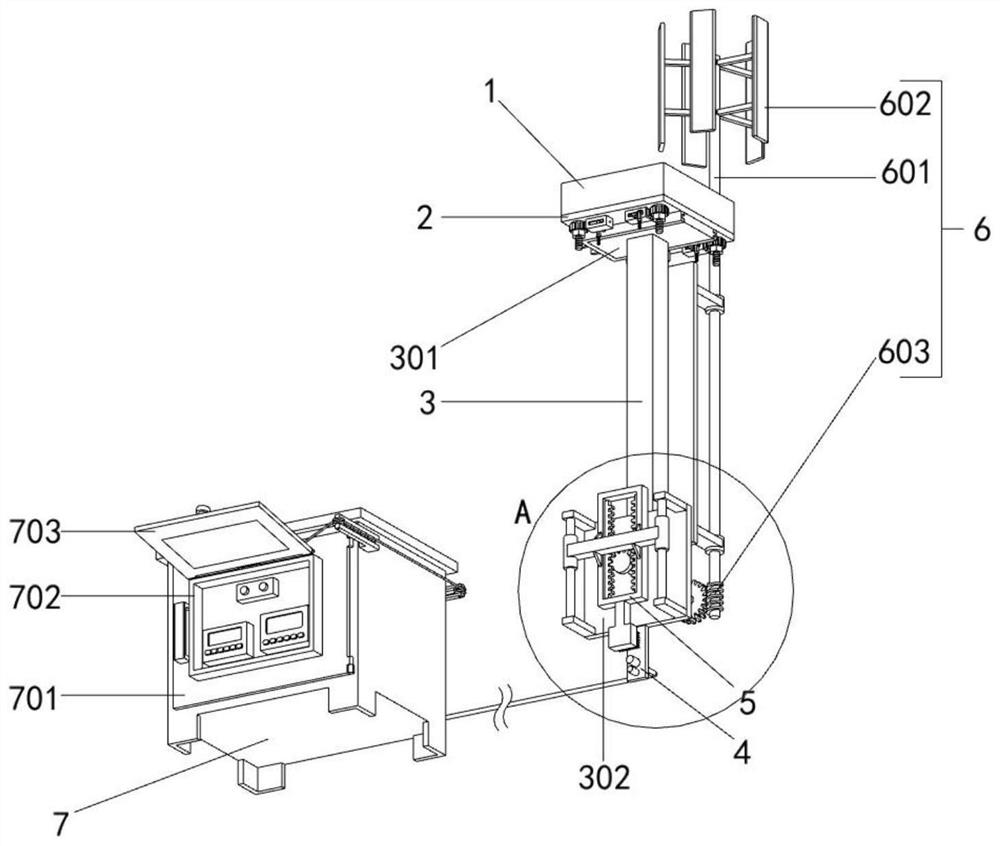

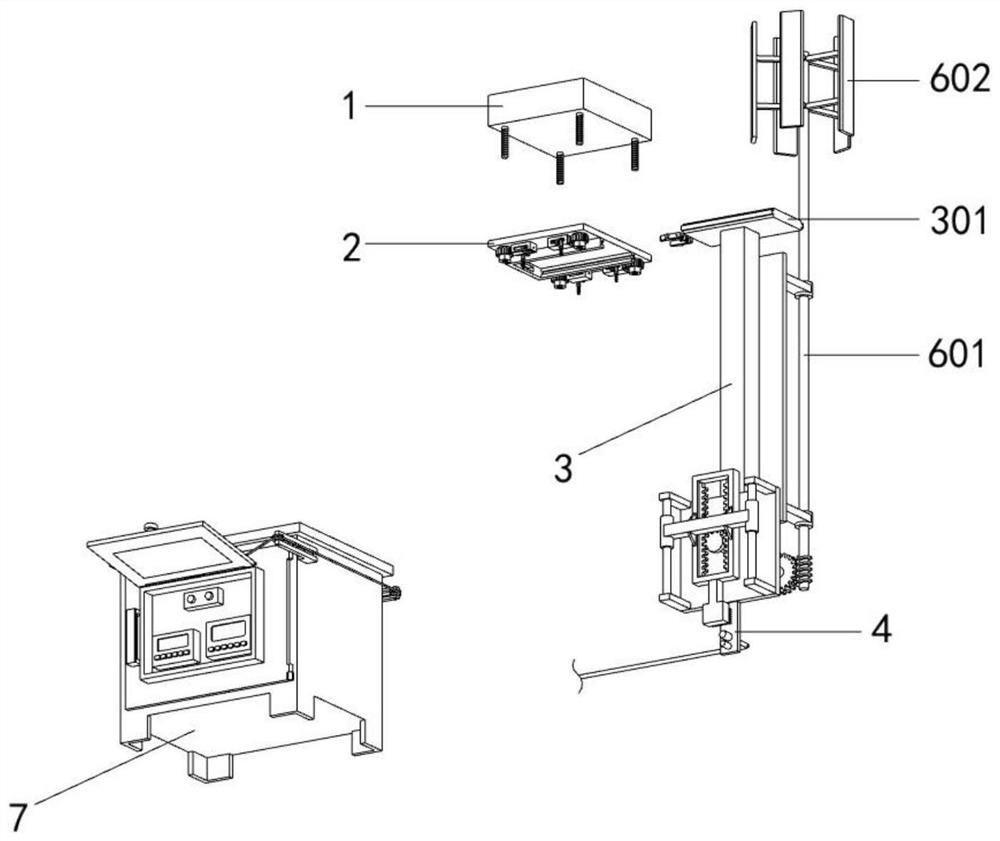

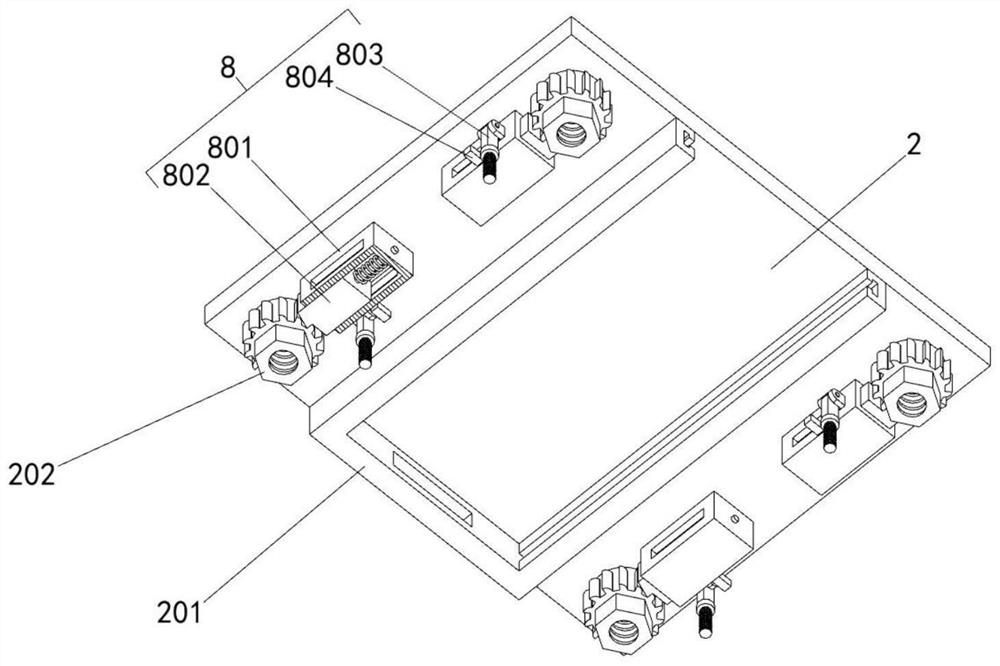

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides a water quality monitoring device, comprising: a concrete support 1; the bottom end surface of the concrete support 1 is connected with a mounting seat 2 through four studs; the mounting seat 2 includes a connecting block 201 and a fastening nut 202, and the mounting seat 2 The middle part of the bottom end surface is provided with a connecting block 201, and the connecting block 201 is a U-shaped structure. T-shaped slide grooves are provided on the front and rear sides of the inner side of the connecting block 201, and the inner side of the connecting block 201 is slidably connected to the support rod 3. The left end surface of the connecting block 201 There is a rectangular bayonet in the middle; the number of fastening nuts 202 is four, and the four fastening nuts 202 are respectively connected to the four studs at the bottom of the concrete support 1 through threads, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com