Vehicle headlights with ventilation system

A technology of headlights and ventilation holes, applied in the direction of headlights, road vehicles, vehicle parts, etc., can solve the problems of no air circulation, internal parts of the casing that hinder air circulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

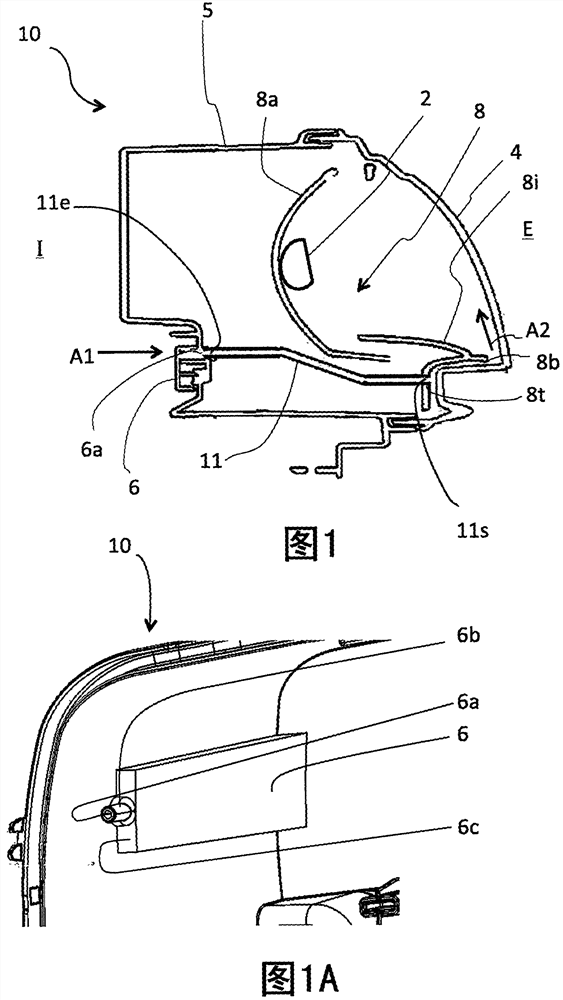

[0035] FIG. 1 shows a schematic cross-sectional view of an embodiment of a vehicle headlamp 10 according to the invention with a duct 11 independent of any other inside the housing 5 of the headlamp 10 Components. This duct 11 has, for example, a bore hole with a diameter of between 5 mm and 7 mm, preferably 6 mm, and between an inlet 11e connected to the hole 6a of the ventilation unit 6 and an end outlet 11s connected to the lower part 8i of the reflector 8 A constant cross section (approximately 7 to 10 mm in diameter, preferably 8.3 to 8.5 mm in diameter).

[0036] The ventilation unit 6 is placed on the inside of the vehicle "I" and therefore on the side opposite the glass 4 which forms the wall for enclosing the headlamp 10 which gives the exterior "E" of the vehicle.

[0037] like Figure 1A The coupling between the inlet end 11e of the duct 11 and the unit 6 is carried out on a cylindrical joint 6b formed on the side 6c of the unit 6 and integrated with the air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com