Automatic clamping device for vacuum glue injection pipeline

A technology for automatic clamping and injection of hoses. It is used in devices and coatings that apply liquid to the surface. It can solve the problems of long operation time, inability to realize automatic control of production lines, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

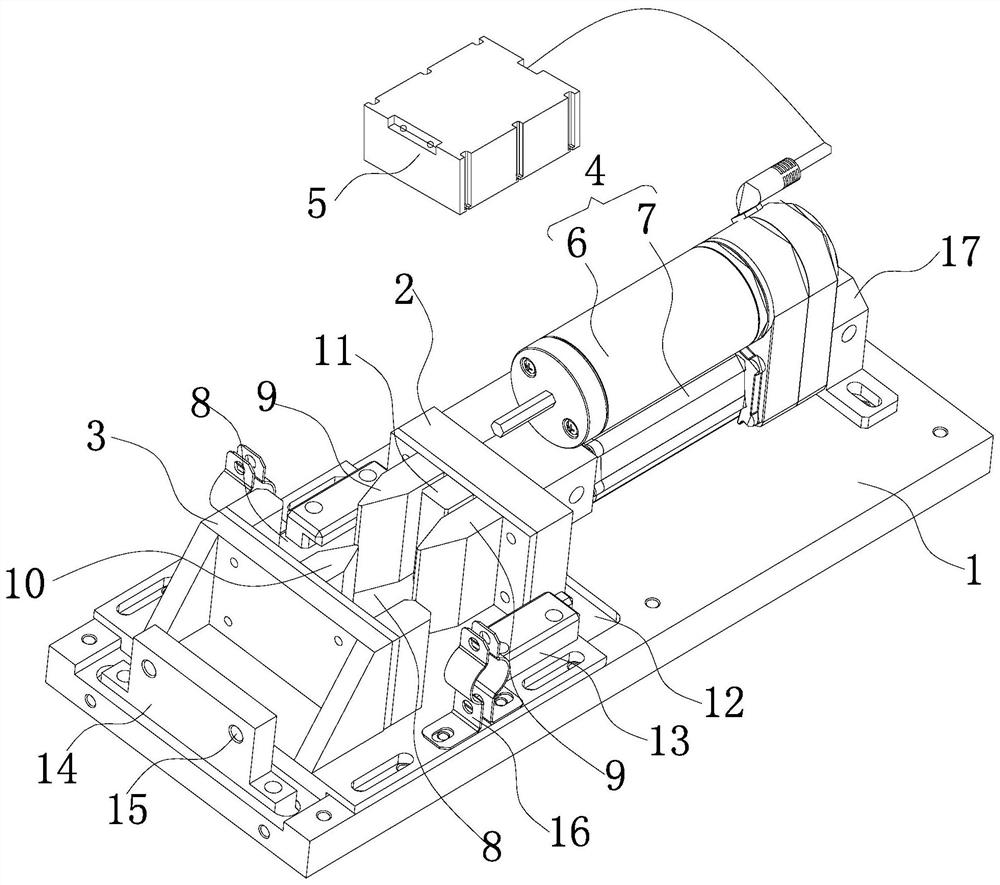

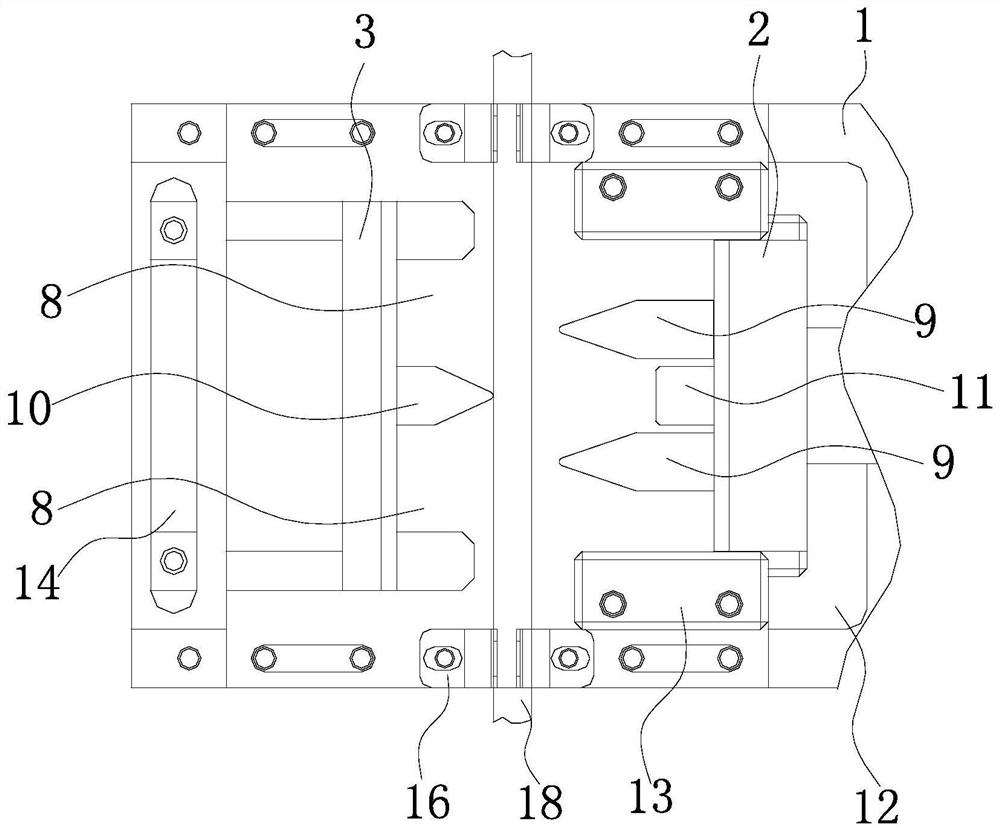

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

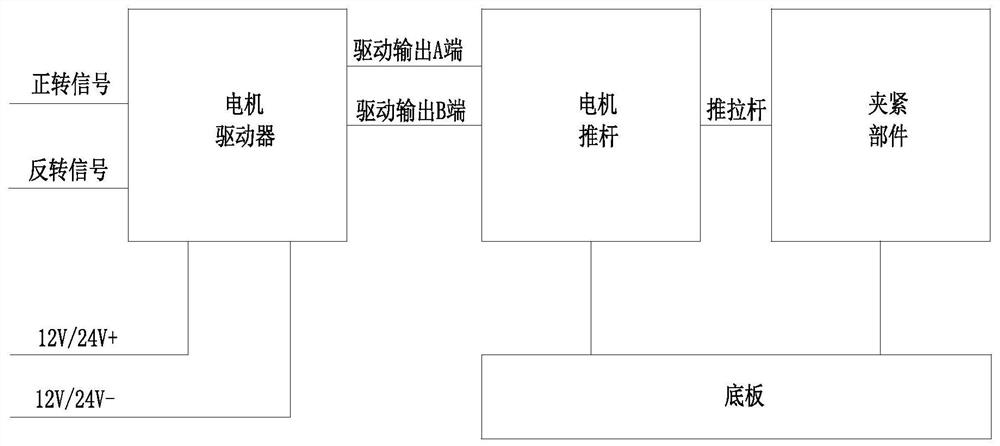

[0026] Please refer to figure 1 and 2 , an embodiment of the present invention provides an automatic clamping device for a vacuum glue injection pipeline, including a clamping component and a power component, wherein the clamping component is an execution component for directly clamping or releasing the glue pipe 18 for conveying glue; The power component is used as a driving component of the clamping component to provide driving power for the clamping component.

[0027] The clamping part includes a bottom plate 1 , a movable block 2 linearly slidably arranged on the bottom plate 1 , and a fixed block 3 opposite to the movable block 2 . specific:

[0028] The bottom plate 1 is a horizontal plate fixedly arranged for carrying the movable block 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com