Food processor

A technology of food processing machine and machine base, which is applied in the direction of utensils with integral electric heating device, anti-overflow, cooking utensils, etc., and can solve the problems of unfavorable function expansion of cup lids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

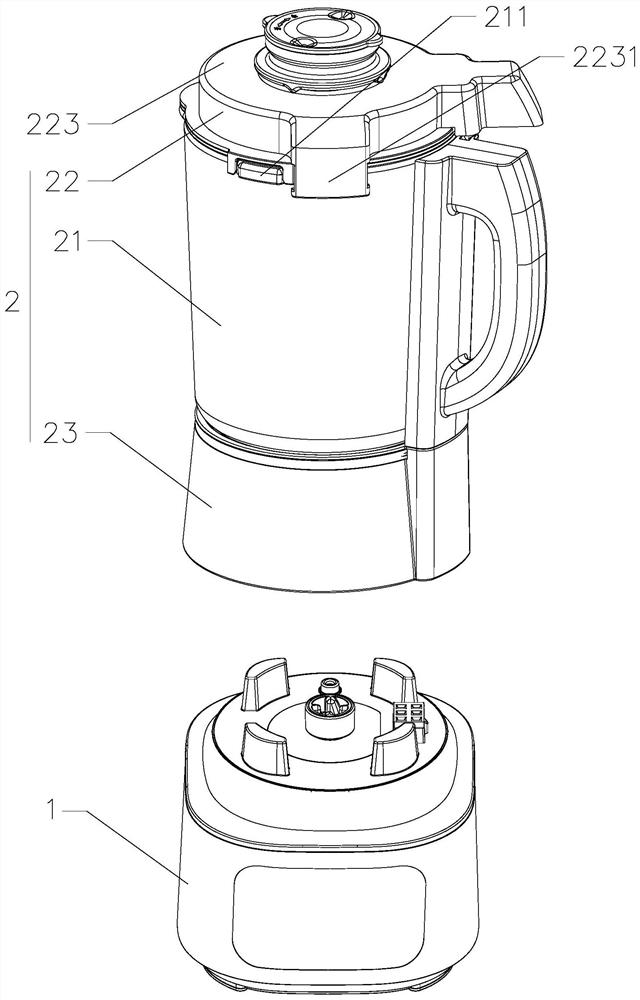

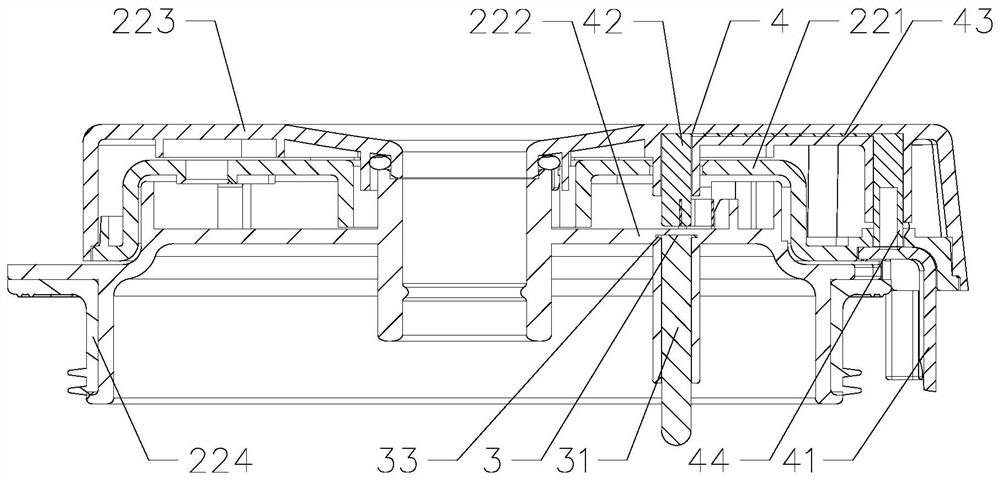

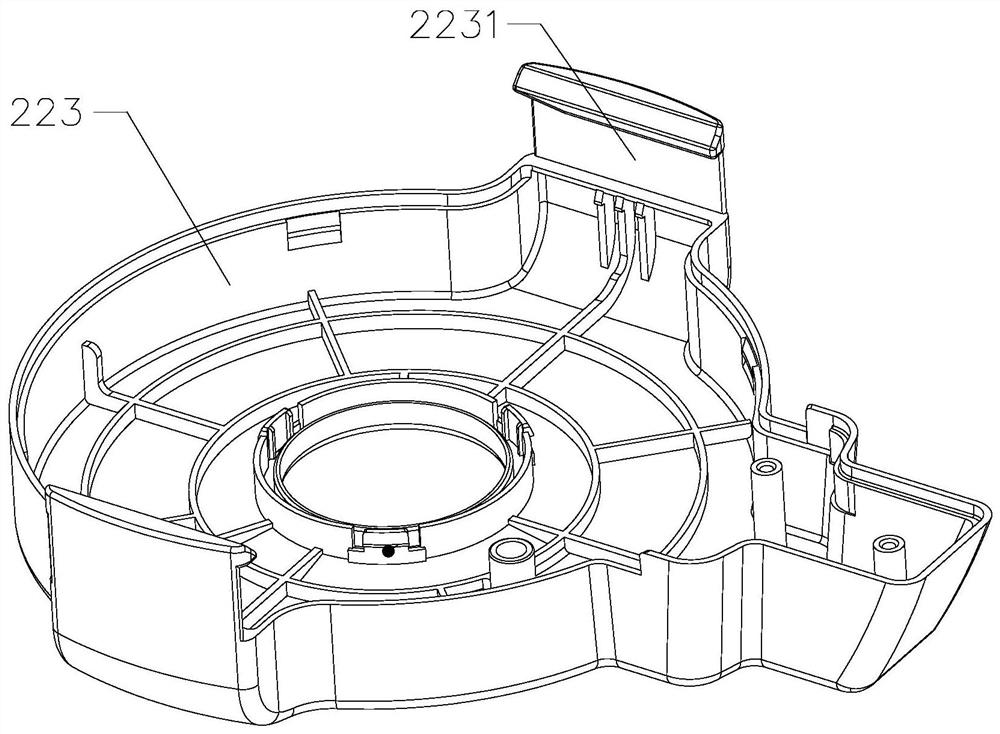

[0043] Such as Figures 1 to 5 As shown, the present invention provides a spill-proof and reliable food processor, comprising a machine base 1, a stirring cup 2 and a heating device, a motor and a control board are provided in the machine base 1, a pulverizer is provided in the stirring cup 2, and the motor drives The pulverizer rotates, and the stirring cup 2 includes a cup body 21 and a cup cover 22 covering the top of the cup body 21. A cup holder 23 is provided at the bottom of the cup body 21. The cup body 21 is a glass cup body. thread, the inner wall of the cup holder 23 is provided with internal threads, the cup body 21 and the cup holder 23 are connected and fixed through the cooperation between the external thread and the internal thread, and the cup holder is provided to ensure that the stirring cup is placed above the machine base Stability, that is to ensure the stability of the mixing cup when the food processor is working, to prevent the stirring cup from shakin...

Embodiment 2

[0053] The difference between this embodiment and the first embodiment lies in that the way of fixing the screw post and the metal connecting piece is different.

[0054] In this example, if Figure 6 As shown, the screw post 34 and the metal connecting piece 33 are fixed by welding, so that the connection is more reliable, so as to ensure the stability and reliability of the conduction of the anti-overflow path.

[0055] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0057] The difference between this embodiment and the first embodiment lies in that the structures of the anti-overflow component and the conductive component are different.

[0058] In this example, if Figures 7 to 8 As shown, the anti-overflow assembly 3 includes an anti-overflow electrode 31, a metal sheet 35 connected to the anti-overflow electrode 31, and the conductive assembly 4 includes a trigger 41, a push rod 45 that cooperates with the metal sheet 35, and connects the trigger part 41 and the push rod 45. After the upper cover 221 and the lower cover 222 are assembled in place, the lower end surface of the push rod 45 is always in contact with the upper surface of the metal sheet 35, that is, the anti-overflow component and the conductive component are normally connected, so that the cup cover 22 and the cup After the body 21 is covered in place, the anti-overflow path is conducted to realize anti-overflow. This method can also ensure the reliability of anti-overflo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap