Integrated double oil cylinder

A dual-cylinder, integrated technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of limited application range, single applicable working conditions, long installation distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

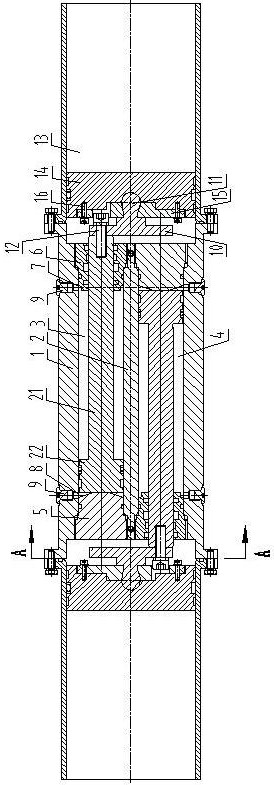

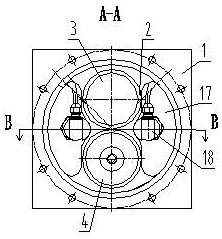

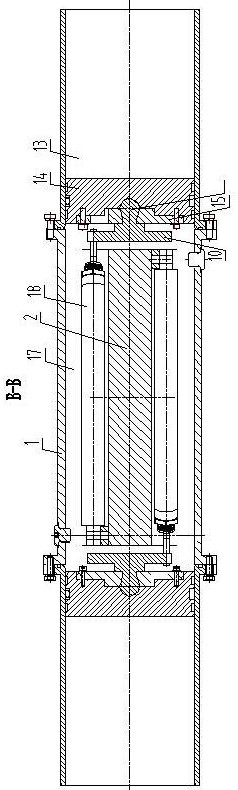

[0014] Such as Figure 1 to Figure 3 As shown, an integrated double oil cylinder of this embodiment includes a main cylinder body 1, is arranged in the main cylinder body 1 through an isolation body 2, two cylinder barrels 3 and 4 arranged radially overlapping, and two detection chambers 17, One end of the two cylinders 3 and 4 is fixedly connected to the cylinder bottom 5 through threads, and the other end is fixedly connected to the guide sleeve 6 through threads. The arrangement directions of the cylinder bottom 5 and the guide sleeve 6 in the two cylinders 3 and 4 are opposite. The two cylinders 3 and 4 are equipped with connected piston rods 21 and pistons 22, and the main cylinder body 1 is provided with two rod chamber oil ports 7 and two rodless chamber oil ports corresponding to the two cylinders 3 and 4 8. Both the rod chamber oil port 7 and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com