Garbage truck with displacement compression function

A technology of garbage trucks and functions, applied in the directions of garbage conveying, garbage collection, garbage storage, etc., can solve problems such as low work efficiency, and achieve the effect of small occupied space, short working cycle period, and increased garbage loading capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

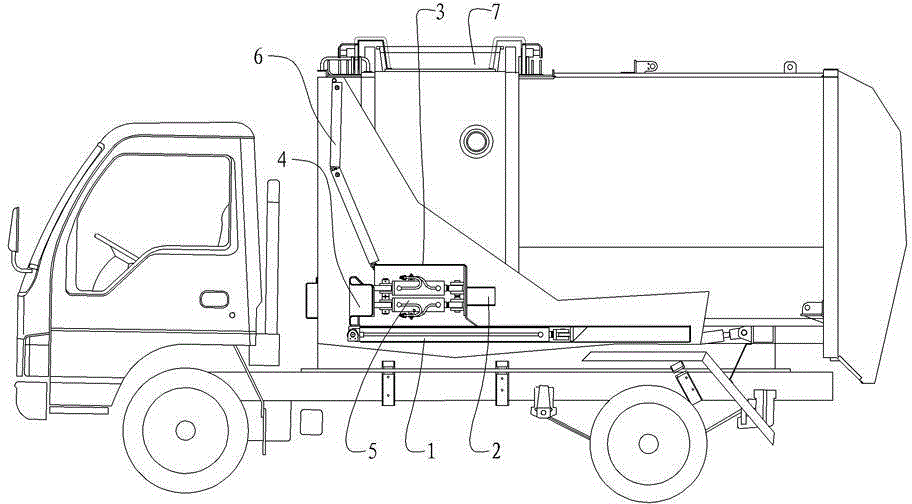

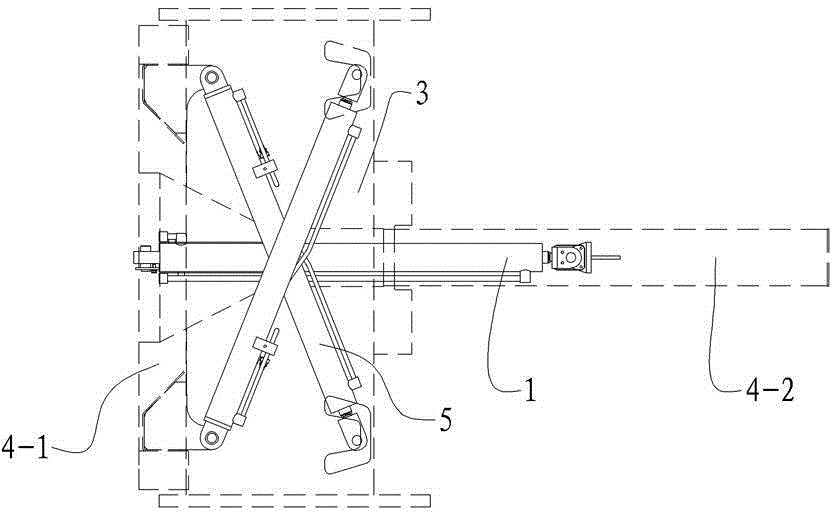

[0024] The present embodiment has the garbage truck of displacement compression function, as figure 1 As shown, it includes a first oil cylinder 1 with one end hinged on the front end of the garbage loading box, at least one horizontal slideway 2 arranged in the box and along the length direction of the box, and at least one horizontal slideway 2 arranged on the inner bottom plate of the box and on the horizontal slideway. The compression head 3 that slides on the top 2 also includes an oil cylinder mount 4 and two second oil cylinders 5 that are located between the compression head 3 and the front end inside the casing.

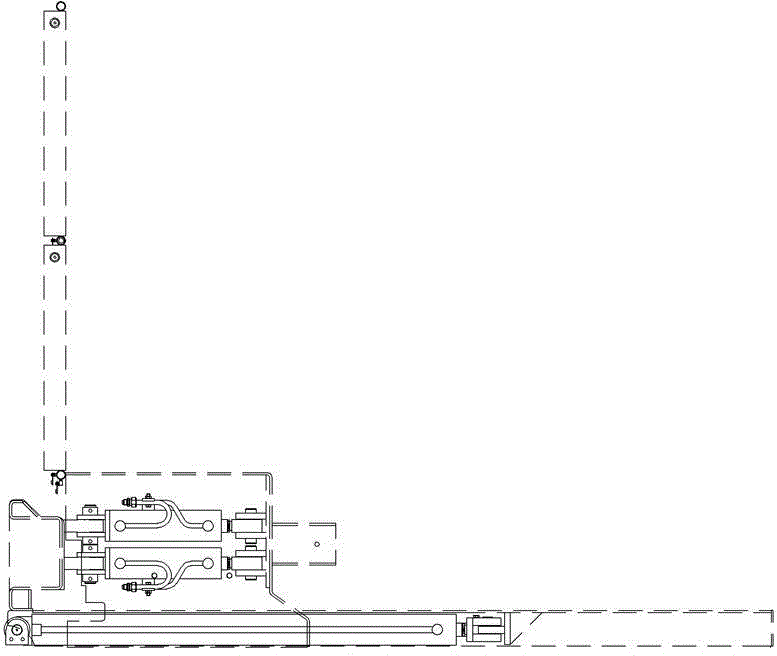

[0025] Such as figure 2 and image 3 As shown, the oil cylinder installation base 4 includes an oil cylinder installation beam 4-1 and an oil cylinder installation longitudinal beam 4-2 arranged parallel to the horizontal slideway. One end of the oil cylinder installation longitudinal beam 4-2 is fixedly connected with the oil cylinder installation beam 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com