Patents

Literature

99results about How to "Short duty cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

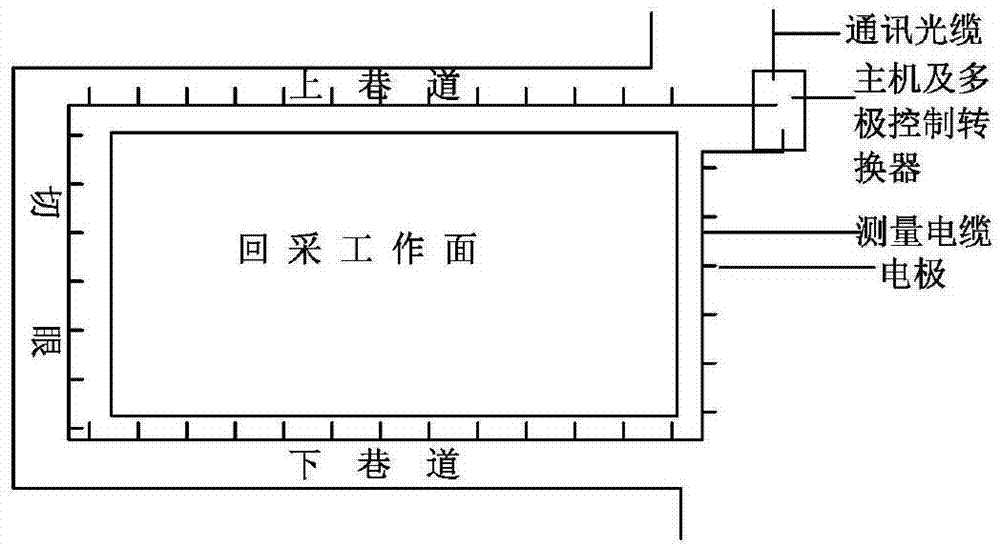

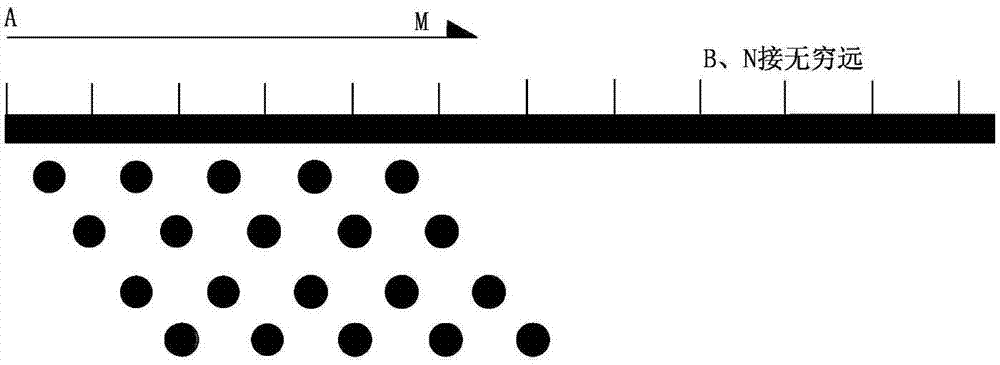

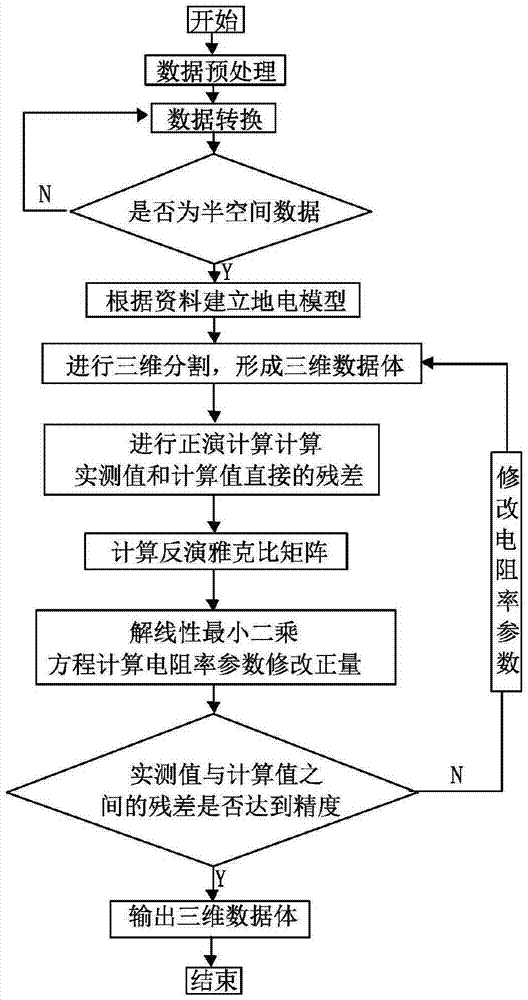

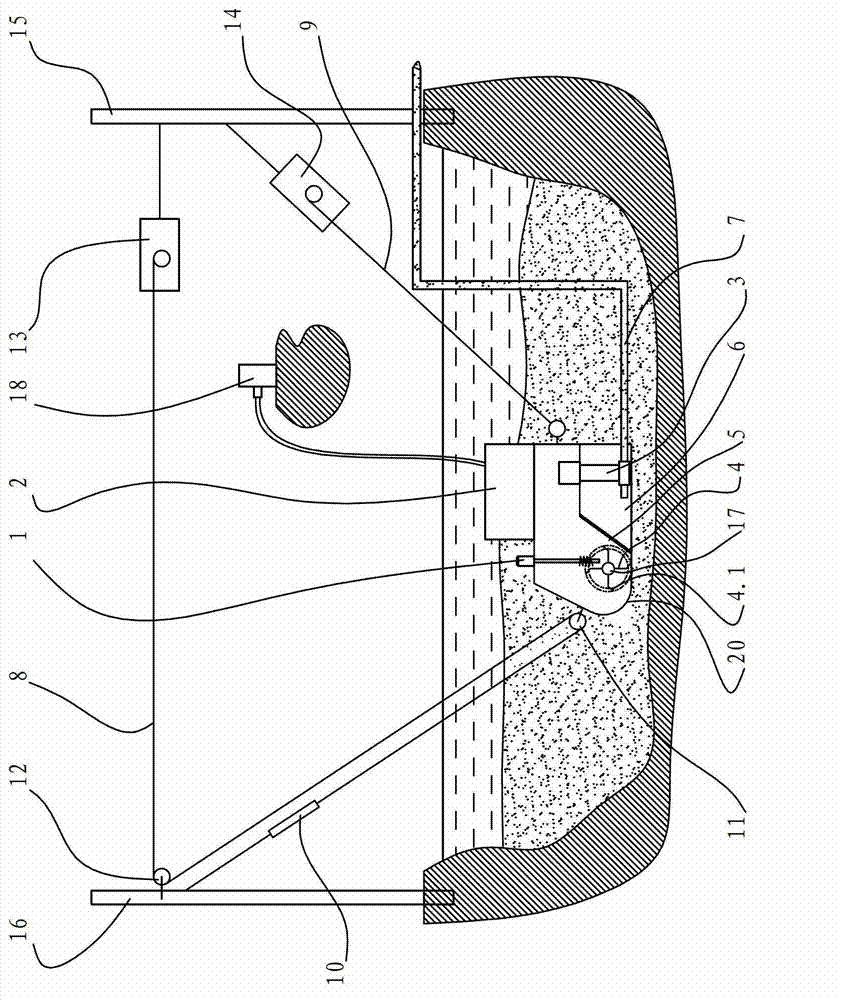

Method for monitoring destroying depth of mining working face base plate in real time

InactiveCN104730585AReal-time monitoring of damage development depthSimple monitoring processElectric/magnetic detection for well-loggingSurveyReal time analysisConfined water

The invention belongs to the technical fields of mine water prevention and control and mine physical geography and relates to a method for monitoring the destroying depth of a mining working face base plate in real time. An electrical resistivity measurement and control mainframe is controlled to automatically acquire data through a multi-pole control converter, acquired data are transmitted through a communication cable in real time, existing underground three-dimensional electrical-method software is utilized to process and analyze the data, the change rule of base plate rock stratum electrical resistivity of the working face in the mining process is analyzed in real time, and real-time monitoring of the destroying depth of the mining working face base plate is achieved according to a destroying depth testing value of the base plate in a field. The method is simple, convenient top operate, accurate in measured data, short in working period, high in efficiency and capable of monitoring the destroying development depth of the base plate in the working face and is suitable for a large-mining-depth high-confined water under-pressure coal mining technology.

Owner:SHANDONG UNIV OF SCI & TECH

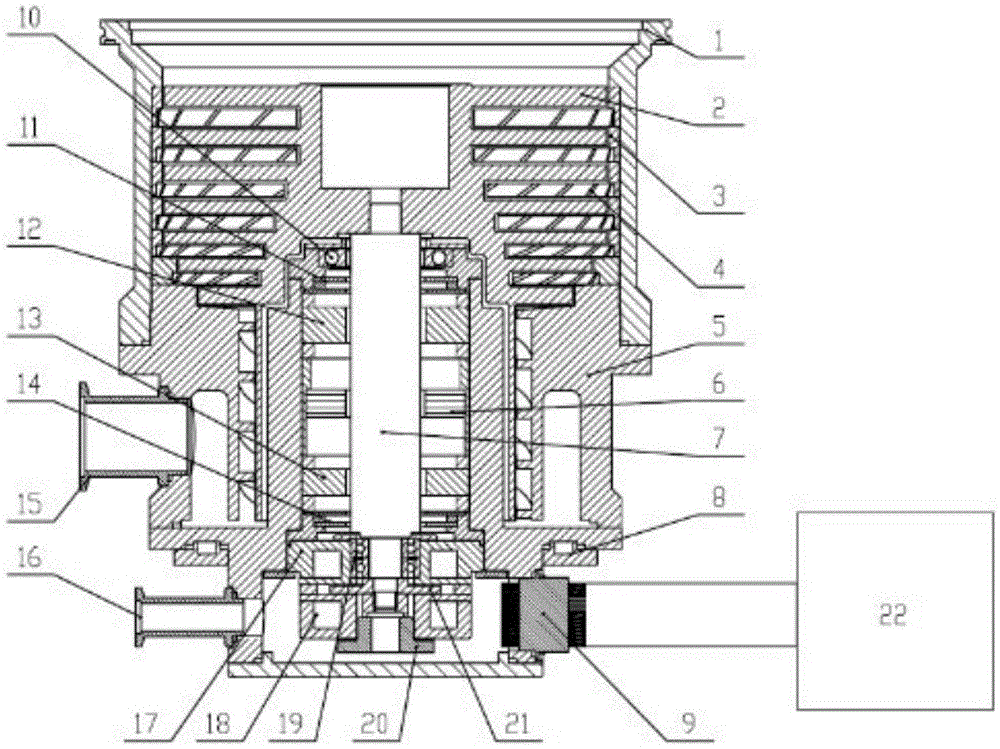

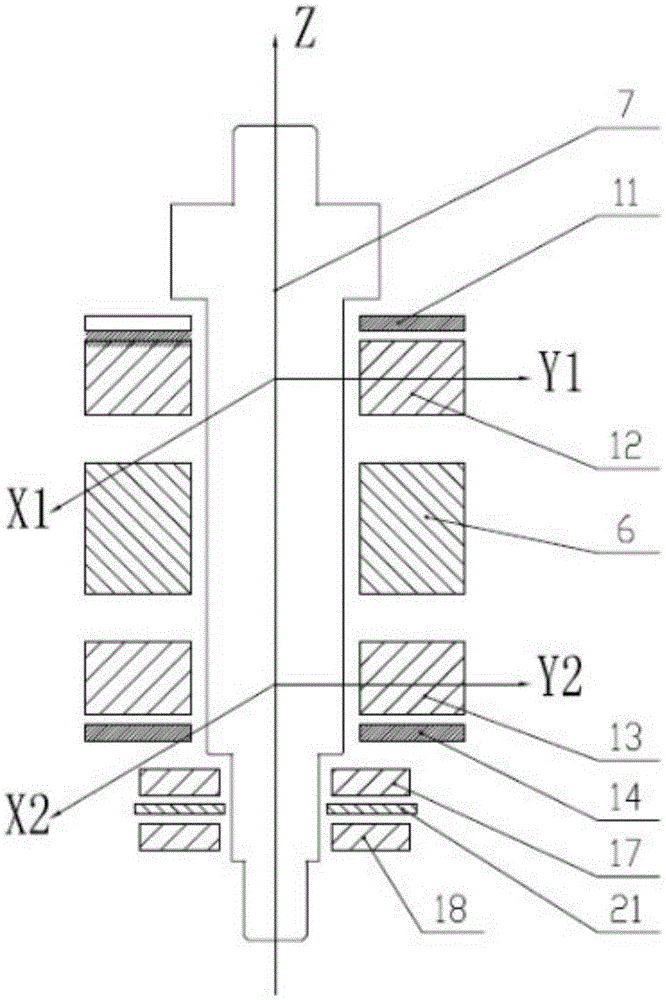

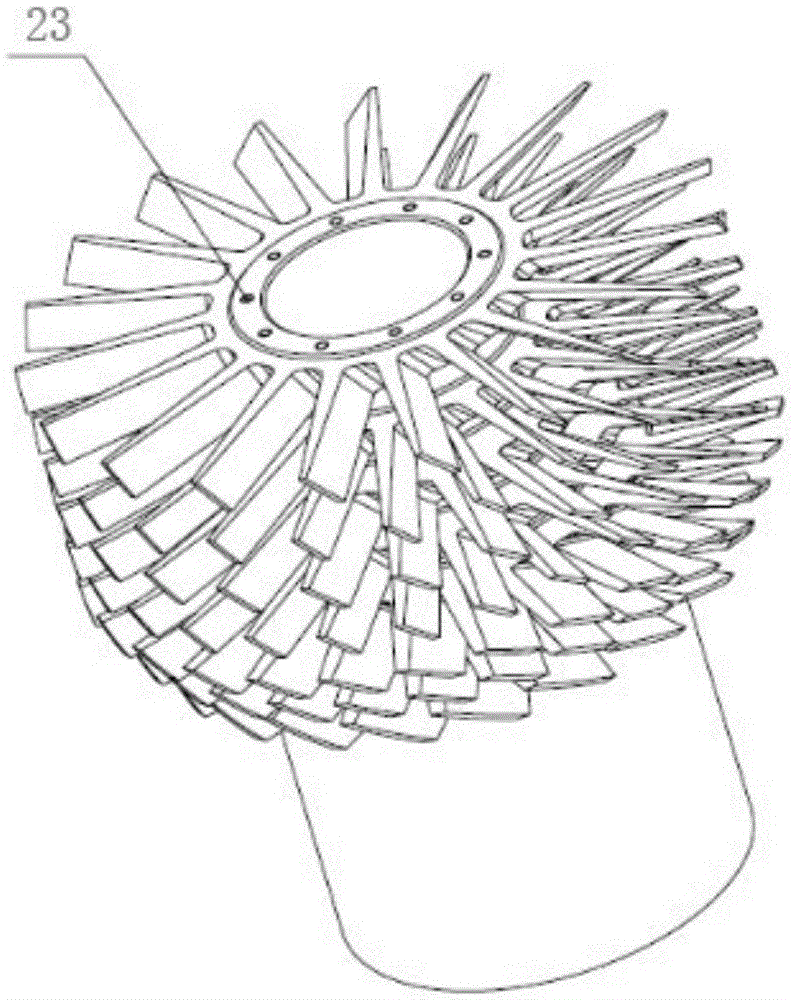

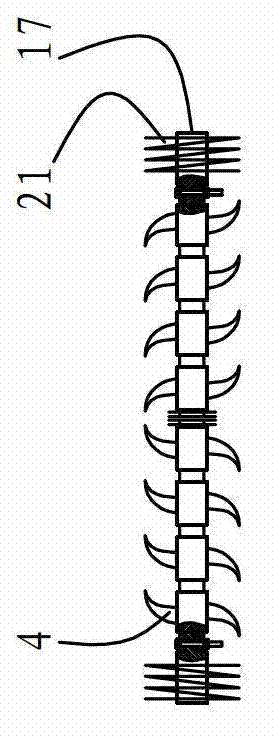

Magnetic levitation compound molecular pump

InactiveCN105526180AExtended service lifeService life is not affectedPump componentsPump controlLow noiseEngineering

The invention relates to a magnetic levitation compound molecular pump which comprises a pump casing, an impeller, spacer rings, stationary blades, a traction-level stator, a permanent magnet high-speed motor, an upper protection bearing, a lower protection bearing, a five-degree-of-freedom magnetic levitation bearing system and a controller. The magnetic levitation compound molecular pump adopts a turbine level and traction level combined design, has a wide pressure range (from 10<-6> Pa to 1 Pa), a high pumping speed, a high compression ratio and a high ultimate vacuum degree, and meets the using requirements of high vacuum and ultrahigh vacuum application industries. meanwhile, the magnetic levitation compound molecular pump adopts a five-degree-of-freedom magnetic levitation bearing, is free of mechanical contact, can achieves a high rotational speed, and has the advantages of no mechanical abrasion, low energy consumption, low noise, long service life, no need for lubrication, no oil stain and the like.

Owner:TIANJIN EMAGING TECH

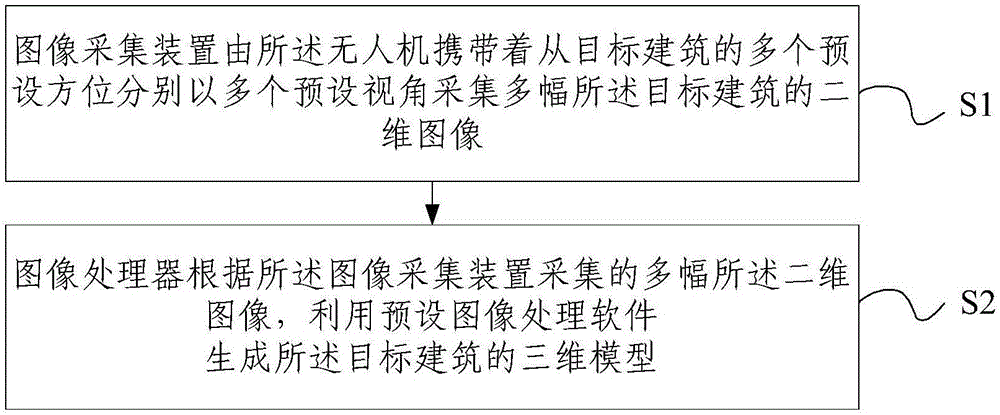

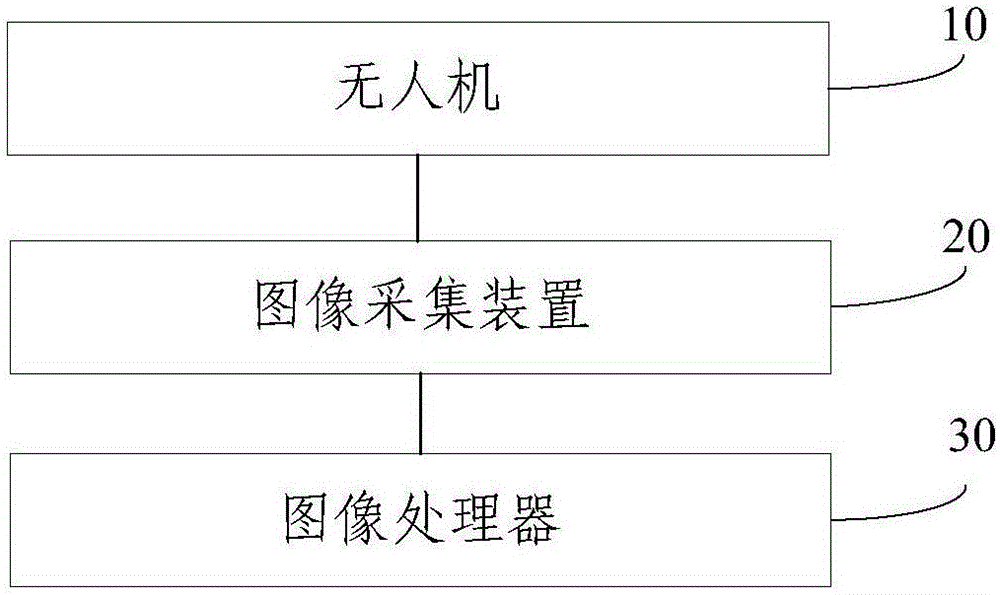

Multi-view three-dimensional reconstruction method and system based on unmanned aerial vehicle

InactiveCN106296821AReduce difficultyLow price3D modellingImaging processingComputer graphics (images)

The invention relates to a multi-view three-dimensional reconstruction method and system based on an unmanned aerial vehicle. The method comprises the steps that, an image acquisition device, carried by the unmanned aerial vehicle, acquires a plurality of two-dimensional images of a target building in multiple preset orientations and from multiple preset views; and an image processing, according to the plurality of two-dimensional images acquired by the image acquisition device, generates a three-dimensional model of the target building by use of preset image processing software. The multi-view three-dimensional reconstruction method and system are advantageous in that, the three-dimensional model of the target building can be generated according to multi-view images of the target building, surface data of a target historic building can be obtained in an overall way, implementing difficulty of the method is low, use devices are cheap, work period is short, fund input is reduced, and the two-dimensional reconstruction is with high precision and good effect.

Owner:刘建国

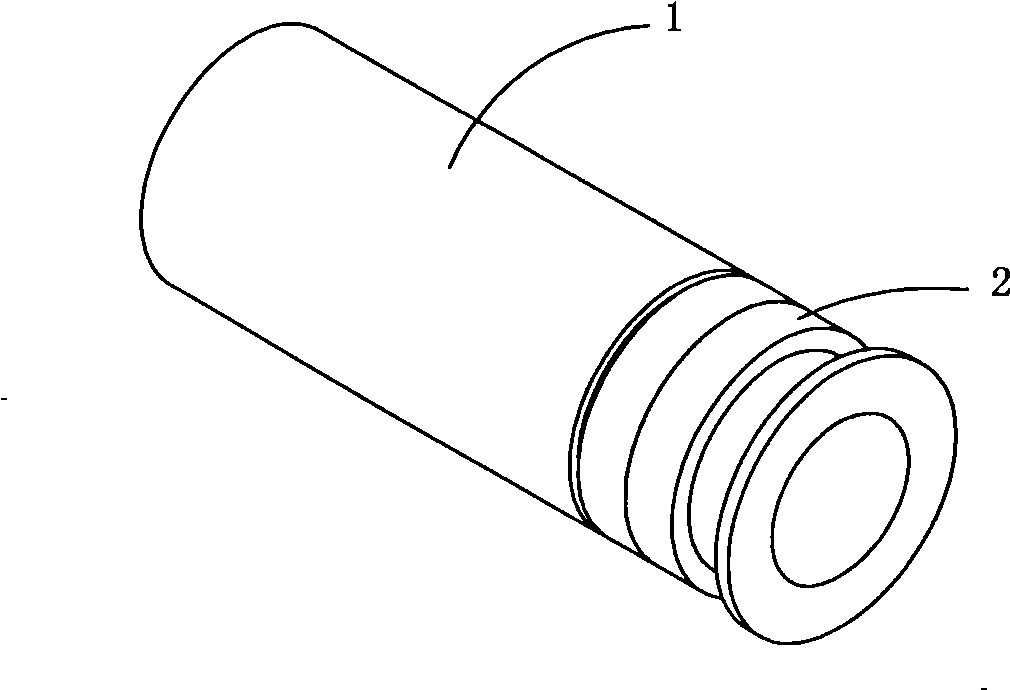

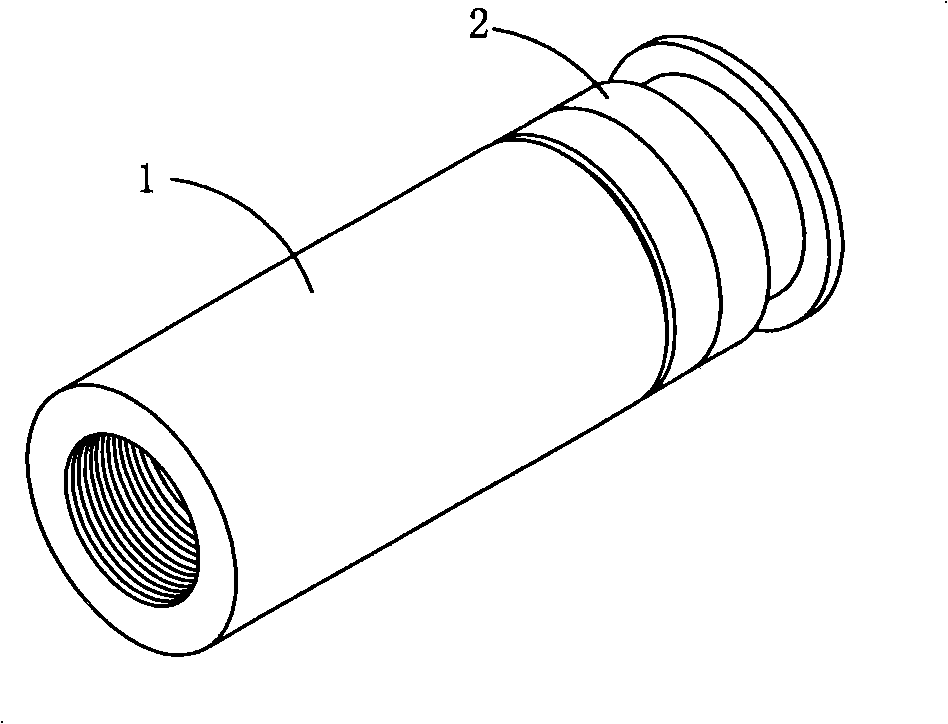

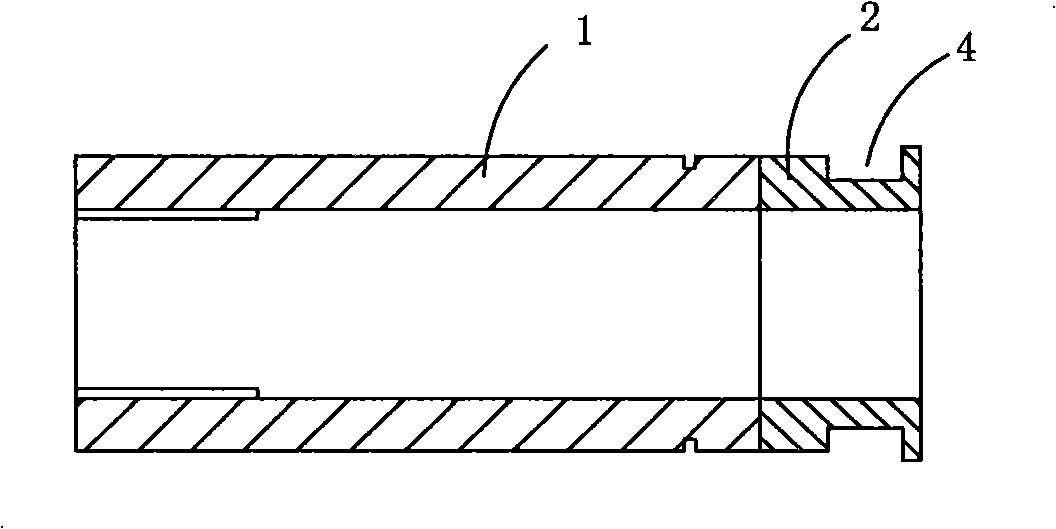

Cuprum aluminum socket connector for conductivity as well as manufacturing method and use thereof

InactiveCN101330174AHigh strengthImprove wear resistanceContact materialsContact member manufacturingElectrical resistance and conductanceLow voltage

The invention discloses a copper-aluminum socket connector for the electric conduction, the preparation method thereof and the application thereof. The socket connector comprises an aluminum body and a copper plug integrated into a whole by welding. The preparation method comprises the following steps: (1) manufacturing the molded aluminum body and the copper plug, and cleaning the welding surfaces of both the aluminum body and the copper plug; and (2) welding the aluminum body and the copper plug into an integrated part by adopting a flash welder or a spin friction welder to obtain the copper-aluminum socket connector semi-product for the electric conduction. The socket connector is mainly applied to a moving contact, a static contact or a conductive contact arm in a high and low voltage switch cabinet or a vacuum circuit breaker. The socket connector has the advantages of non-contact resistance, no galvanic corrosion, smaller resistance, less current conveyance loss, improved current transmission efficiency and reduced power transmission and transformation loss.

Owner:梁楚欣

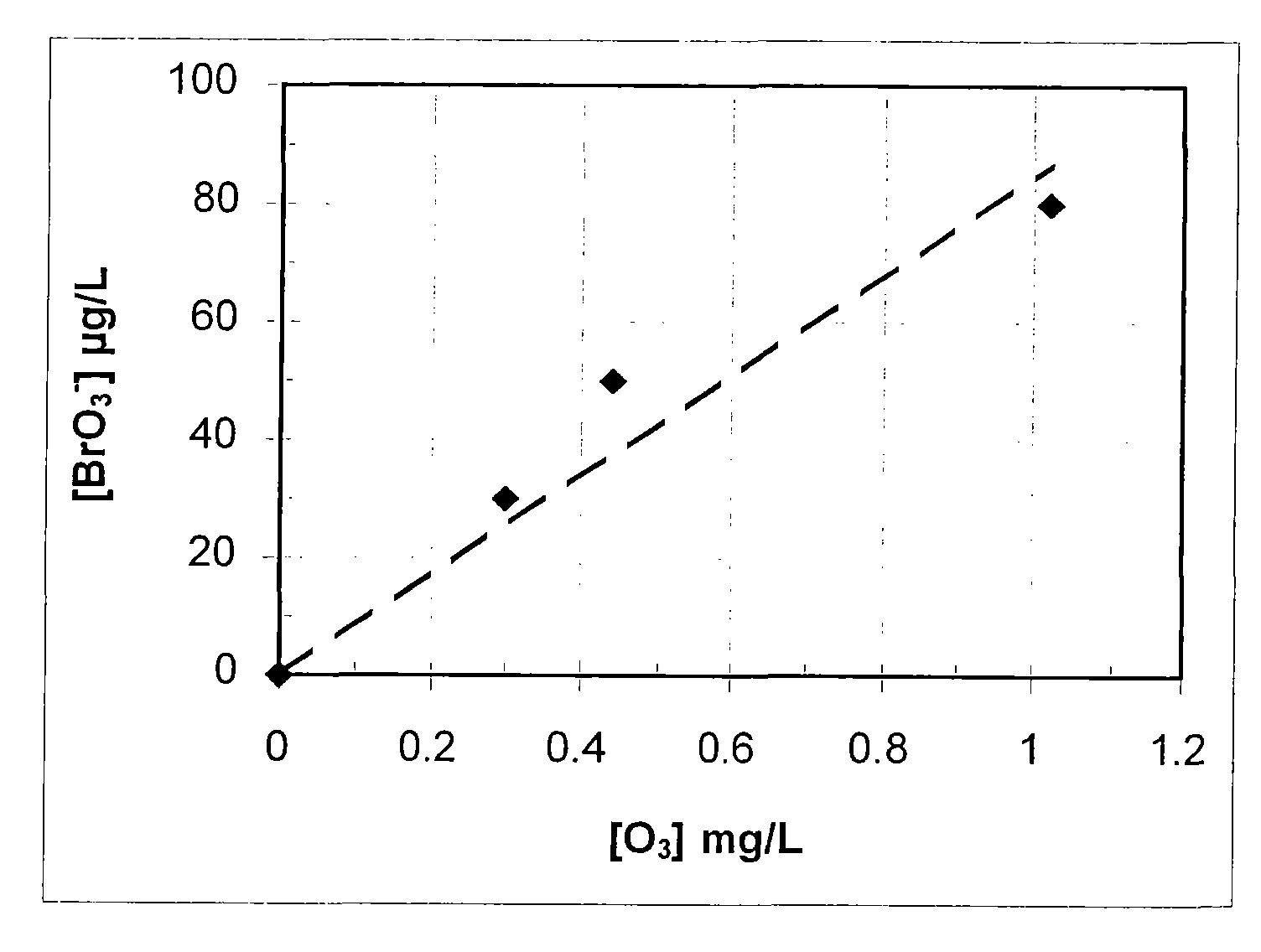

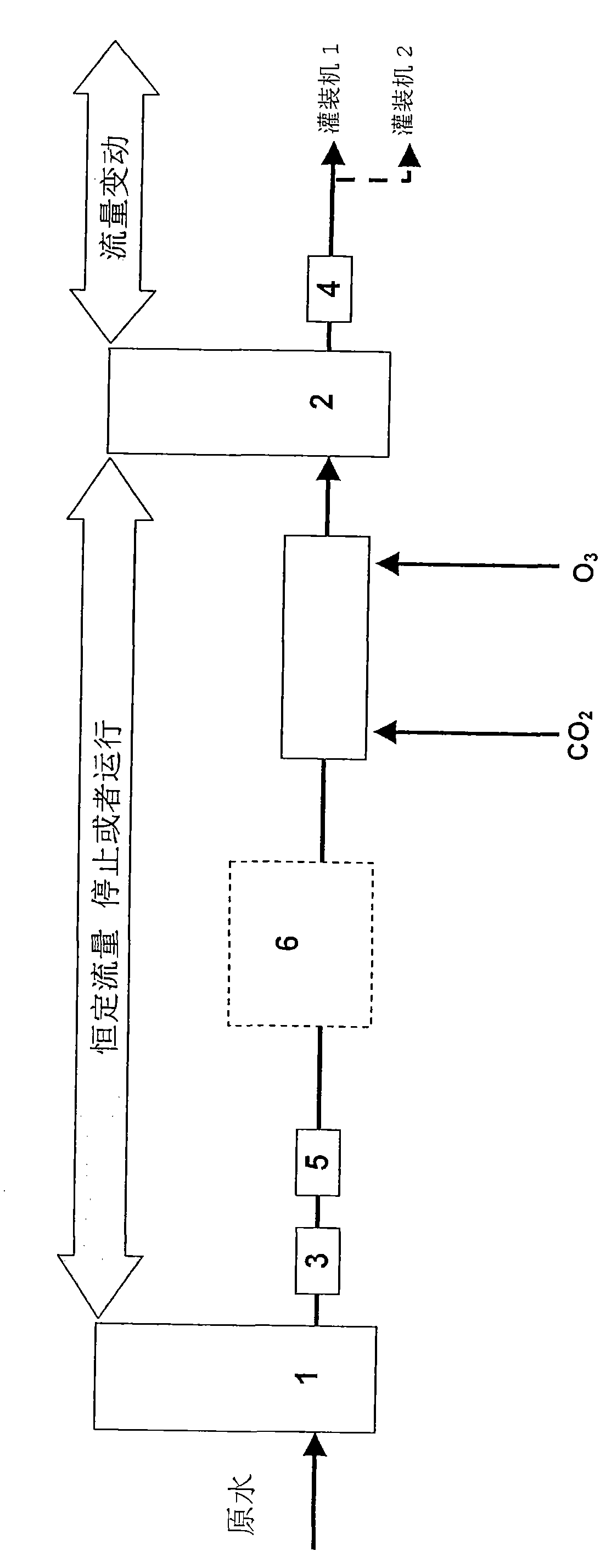

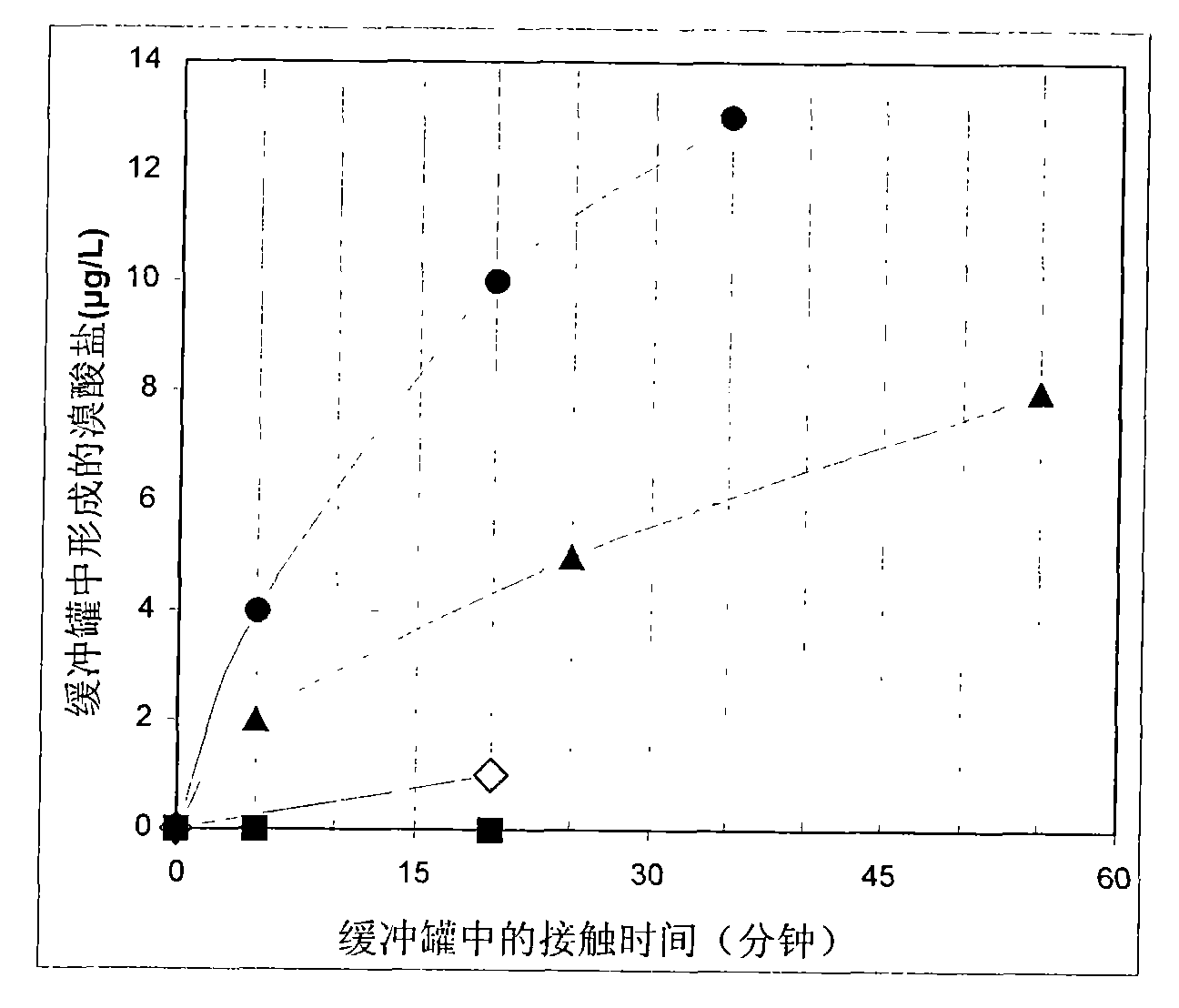

Process for producing bottled water sterilized by ozone and sterilized bottled water

InactiveCN101549900AImprove solubilityPlay a role in separatingWater/sewage treatment using germicide/oligodynamic-processOzone preparationBuffer tankWater flow

The invention relates to a process for producing bottled water sterilized by ozone, which comprises the following continuous steps: gathering original water in an original water tank (1), and pumping the water from the original water tank (1) to a buffer tank (2); injecting ozone before the water is pumped to the buffer tank (2); bottling the ozonized water through a filling machine after the water is pumped to the buffer tank (2). The process is characterized in that the water flow is maintained at a constant value between the original water tank (1) and the buffer tank (2), and the ozone which has stable concentration and can be transiently used is injected in the water.

Owner:DES EAUX MINERALES DEVIAN S A E M E

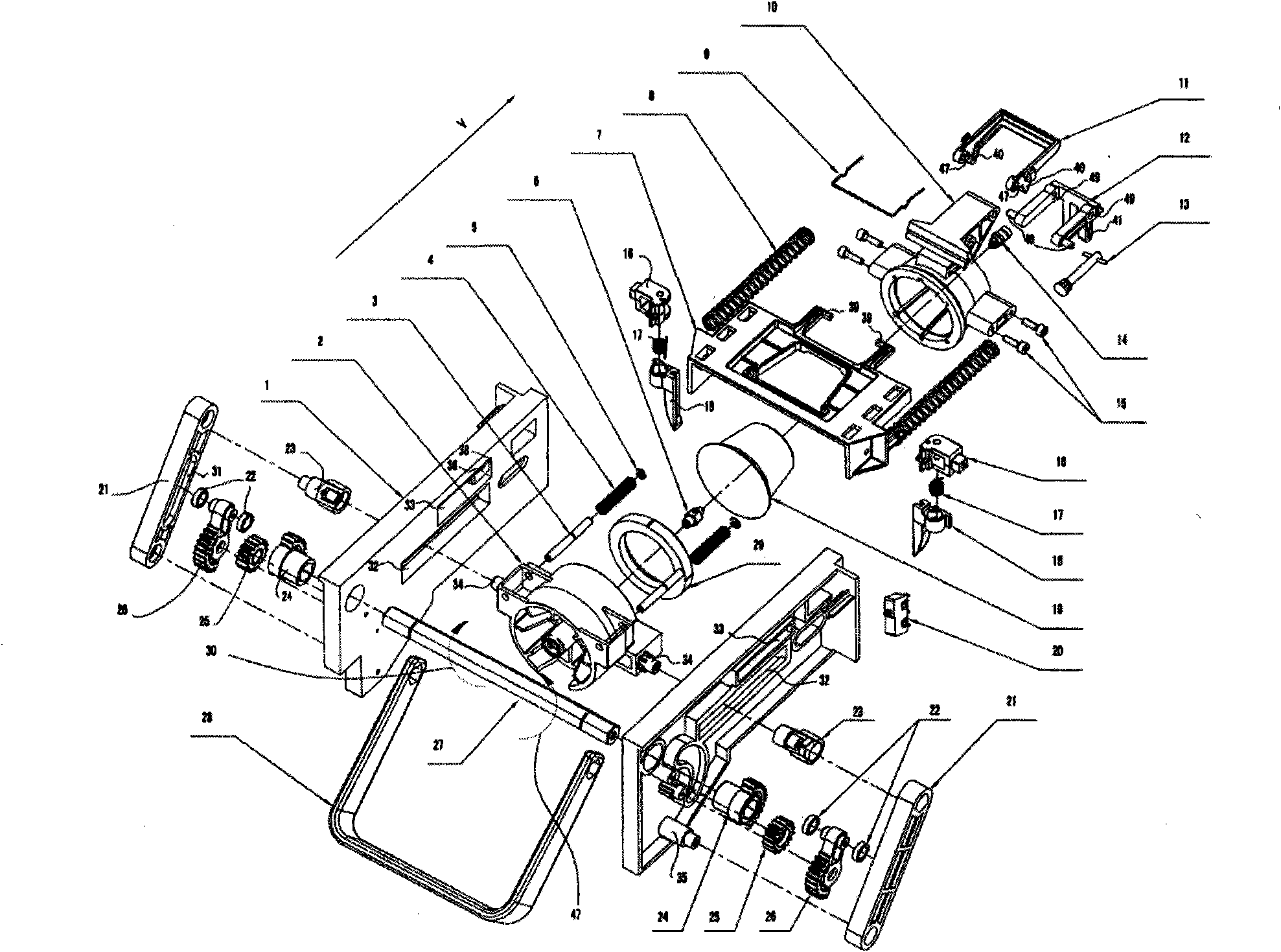

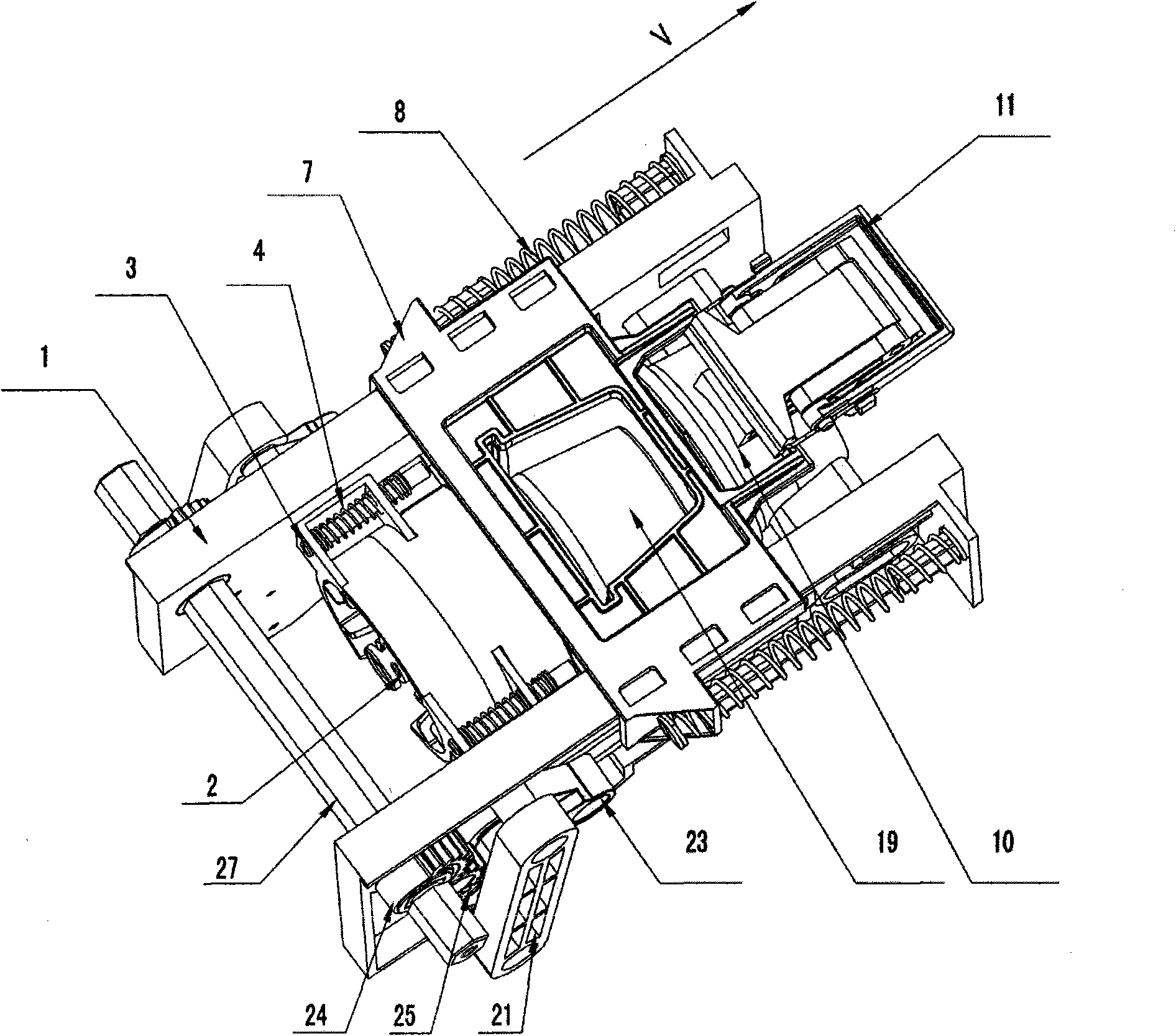

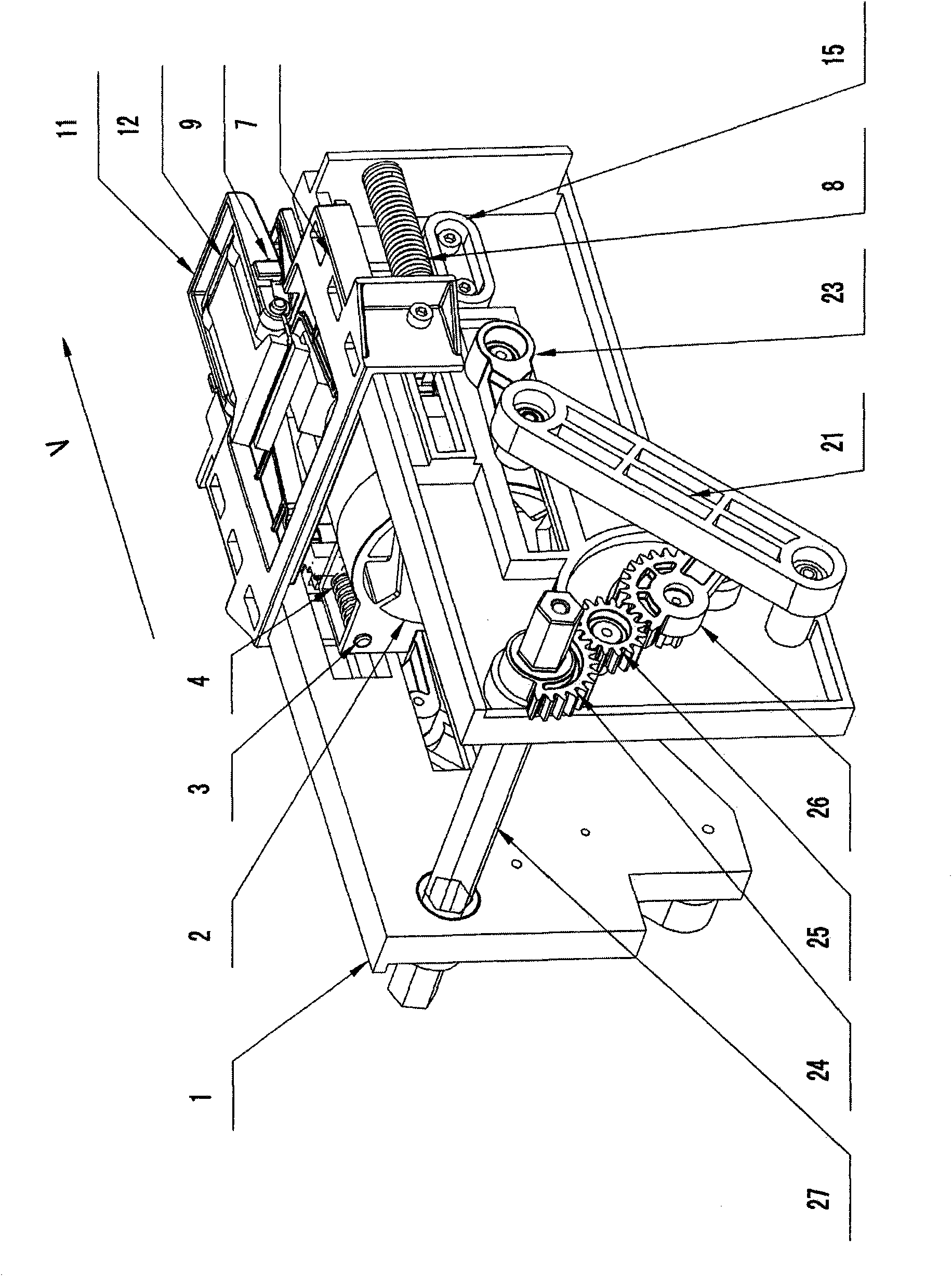

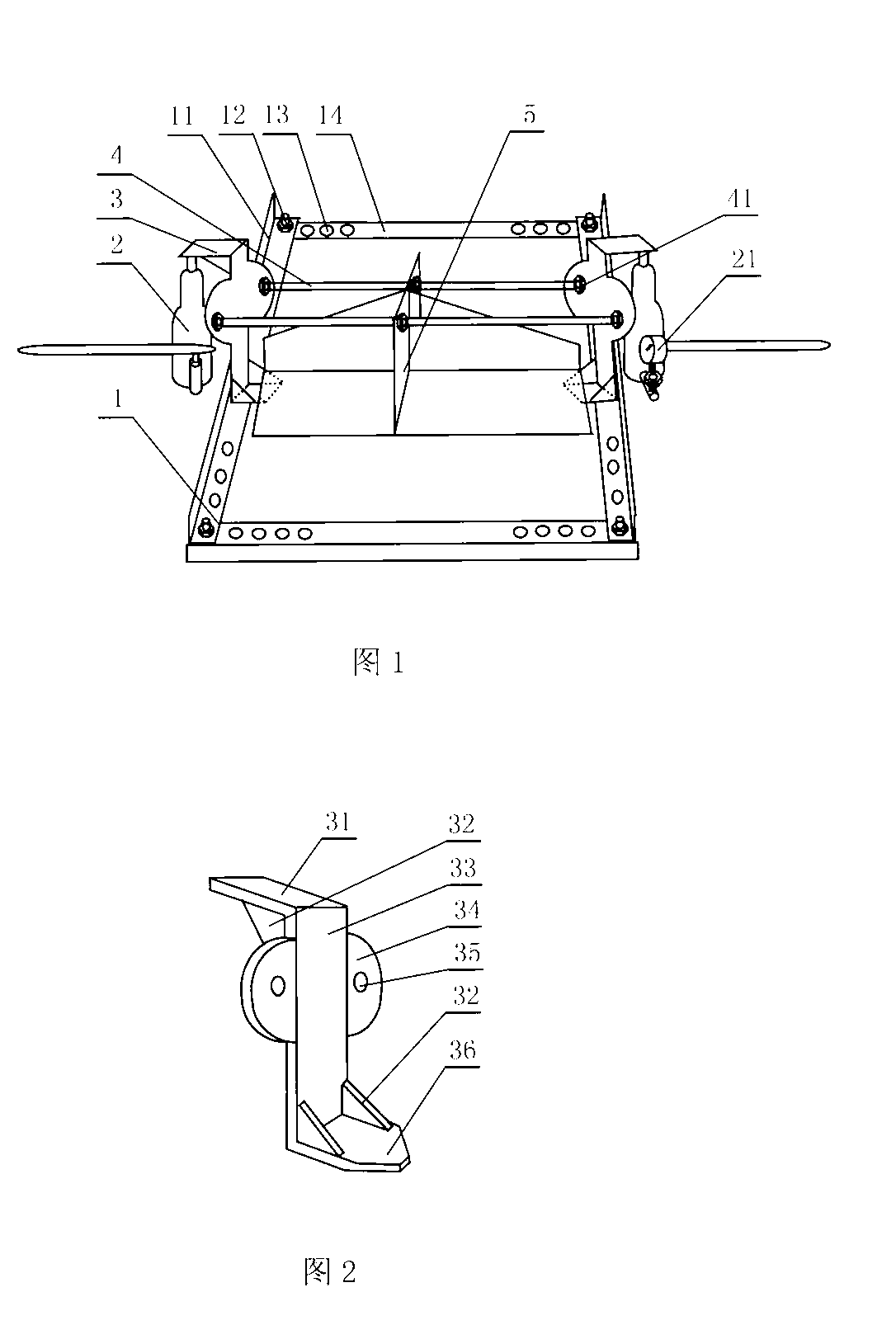

Manual capsule coffee maker

The invention relates to a manual capsule coffee maker which comprises brewing mechanisms (2, 6, 10, 14 and 29), driving mechanisms (21-27), capsule feeding mechanisms (3,4,5 and 7), capsule guiding mechanisms (15-18) and capsule automatic push-out mechanisms (8-13) and is characterized by also comprising a bracket (1),wherein the bracket (1) is provided with gear structures (36 and 38); the capsule guiding mechanisms (15-18) at least have coffee capsule gripping positions and coffee capsule releasing positions; during operation, the brewing mechanisms (2, 6, 10, 14 and 29), the brewing mechanisms (2, 6, 10, 14 and 29), the capsule guiding mechanisms (15-18) and the gear structures (36 and 38) works together to switch the capsule guiding mechanisms (15-18) between the coffee capsule gripping positions and the coffee capsule releasing positions. The invention has the advantages of reliable performance, shorter working period and less mechanical parts.

Owner:SUZHOU KALERM COFFEE MASCH TECH CO LTD

Improved wheat shoot apex transformation method induced by agrobacterium

InactiveCN1633839AOvercome conversion limitationsEasy to getFermentationGenetic engineeringShoot apexTriticeae

The invention discloses an improved wheat shoot apex transformation method induced by agrobacterium which comprises, (1) subjecting the seeds to vernalization for 20-30 days at 4 deg. C after germination, (2) activating bacillus which contains destination genes, (3) cutting the seedling of suitable size, exposing or damaging growing point positions, (4) dropping the bacillus droplet containing the destination genes onto the seedling incision, (5) recovering seedling growth, transplanting into soil for cultivation, screening antibiotics to obtain transgene strains and filial generation, (6) identifying transgene strain and the filial generation.

Owner:SHANDONG UNIV

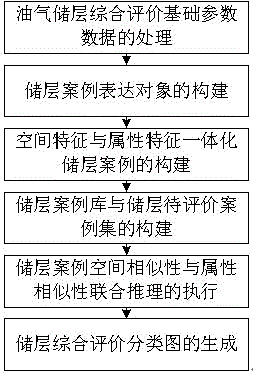

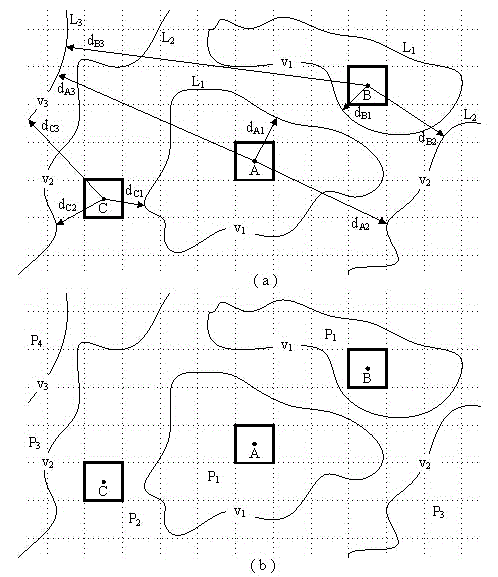

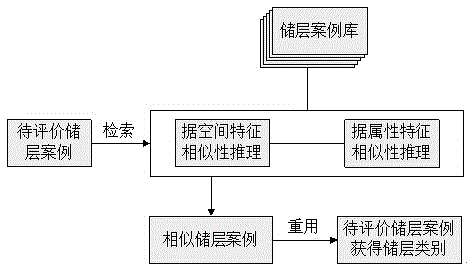

Oil and gas reservoir comprehensive assessment oriented spatial case-based reasoning method

InactiveCN104598766ANon-specialistRealize evaluationSpecial data processing applicationsReservoir typeGrid pattern

The invention discloses an oil and gas reservoir comprehensive assessment oriented spatial case-based reasoning method. The method comprises the following steps: (1) aiming to a position of a to-be-assessed area of the oil and gas reservoir, determining types of various drilled reservoirs, interpolating basic parameters of the drilling, and exporting the result; (2) partitioning the to-be-assessed area into grids and generating a grid pattern layer, wherein each of the grids is a case expression object; (3) extracting the basic parameter attribute, a spatial feature value and the reservoir type (a part of grids have) corresponding to each of the grids in the pattern layer; (4) respectively exporting all and provided grid information of the reservoir types in the grid pattern layer, and constituting a reservoir to-be-assessed case set and a case library; (5) setting weights, finding the case with the highest similarity from the case library according to the spatial similarity and / or attribute similarity of each case in the to-be-assessed case set, and attaching the reservoir type to the to-be-assessed case; (6) correlating all the obtained cases of the reservoir type to the grid pattern layer, coloring the grids according to the type, and at last obtaining a reservoir comprehensive assessment classification chart.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +3

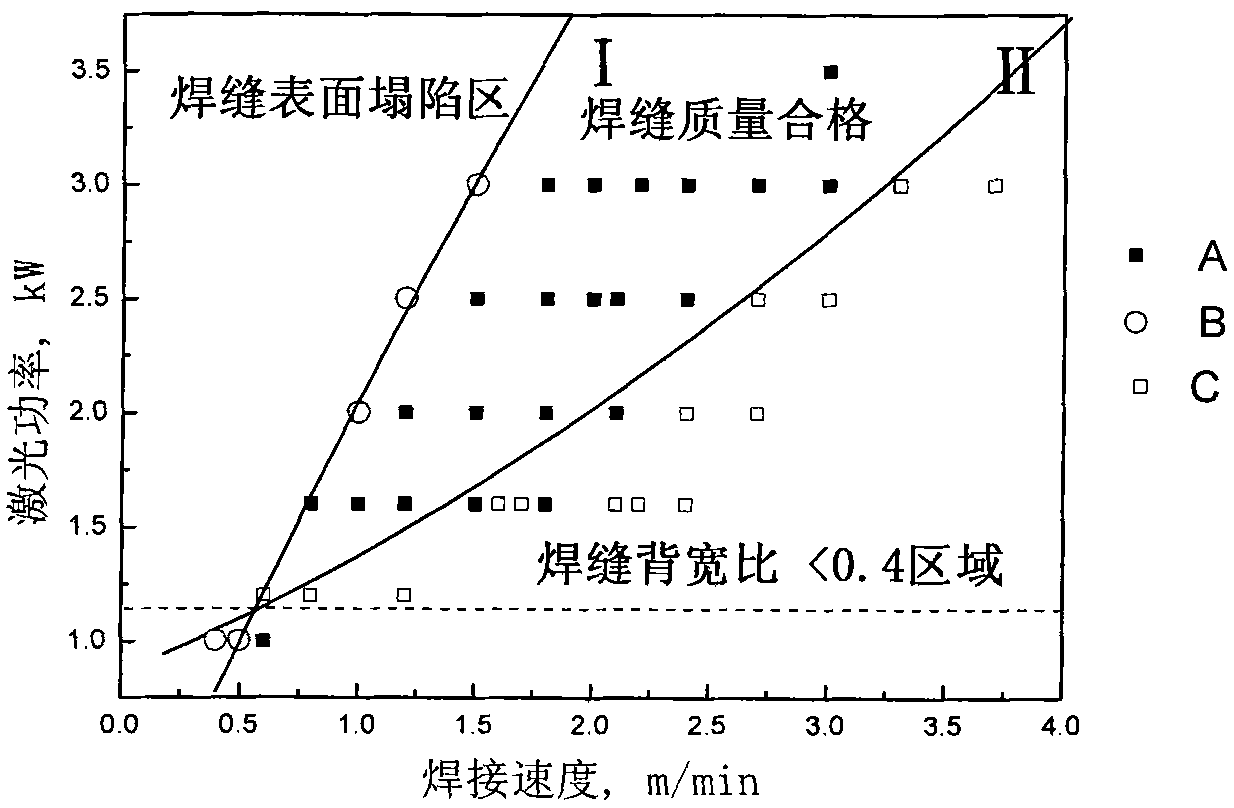

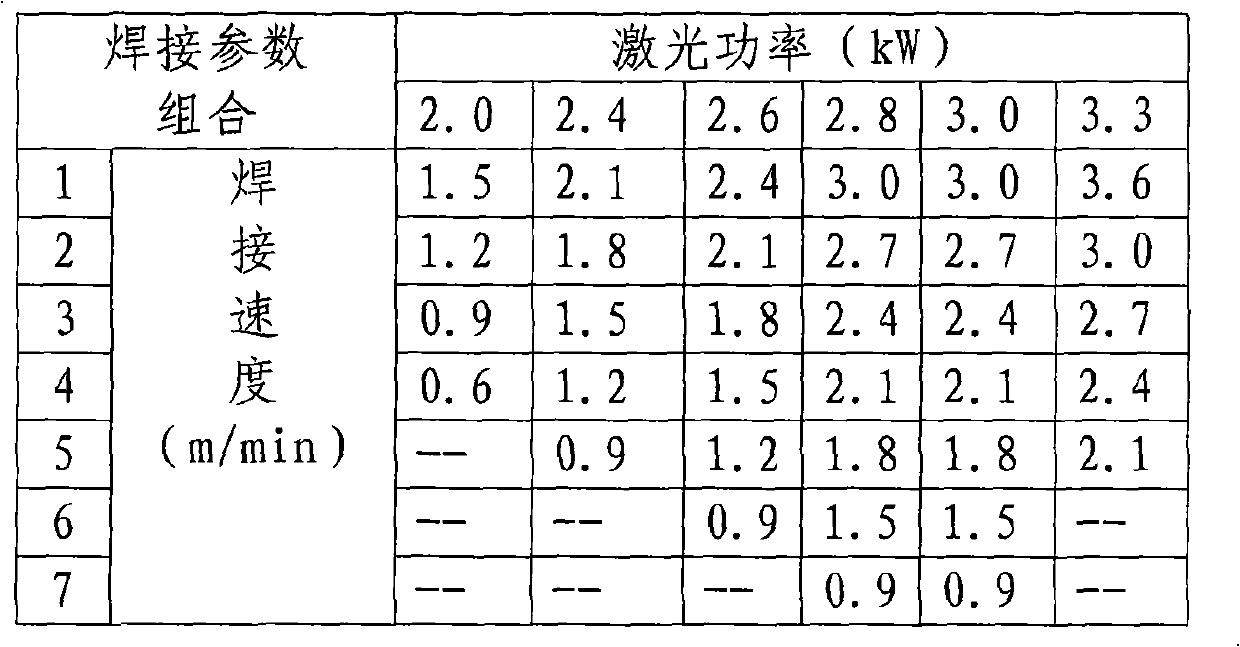

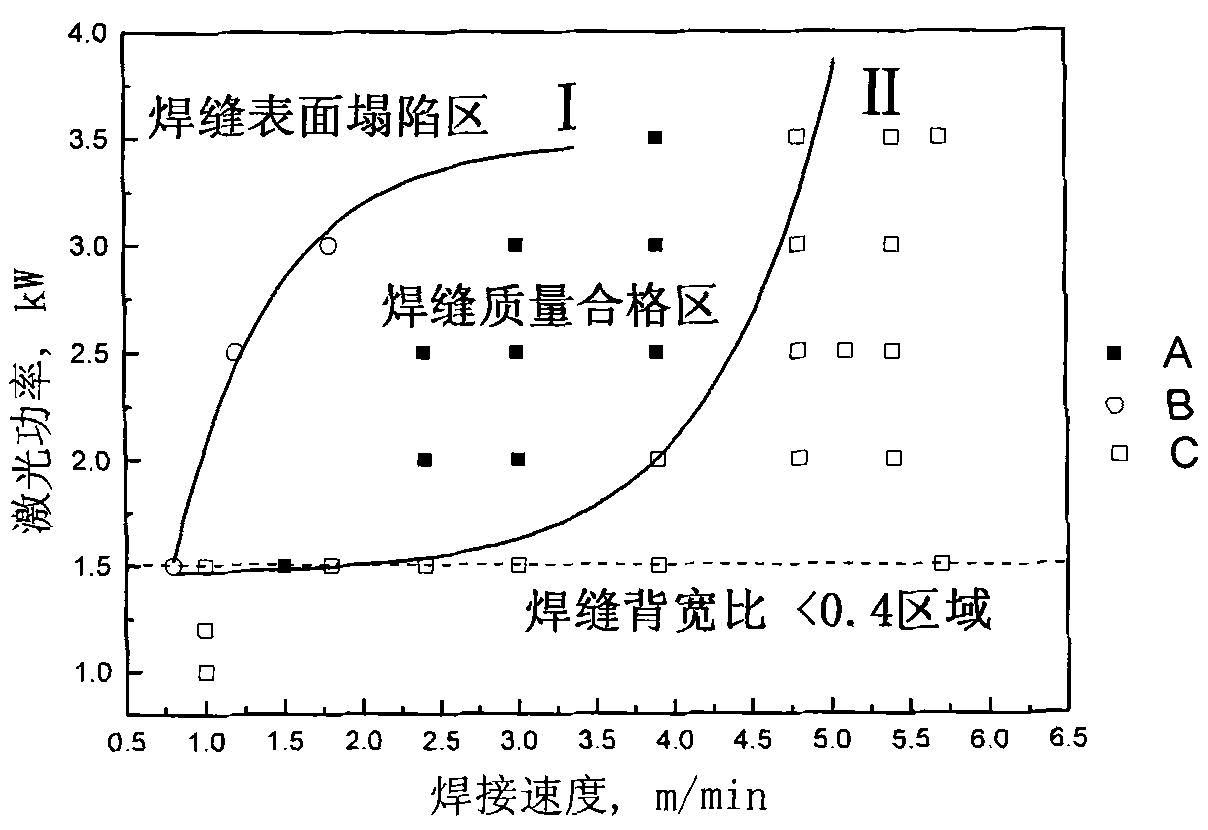

Method for determining full penetration laser welding process parameter of sheet

InactiveCN101905380AGuaranteed weld qualityShort duty cycleLaser beam welding apparatusWork periodLaser

The invention belongs to laser welding technology, and relates to a method for determining a process parameter during full penetration laser welding of a metal sheet with the thickness of less than 3 millimeters. The method for determining the process parameter is characterized by comprising the following steps of: defining; establishing a full penetration laser welding process parameter window of the sheet; and determining the full penetration laser welding process parameter of the sheet. The method can ensure weld quality, does not need metallographic phase sampling analysis, and has short work period and low welding cost.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

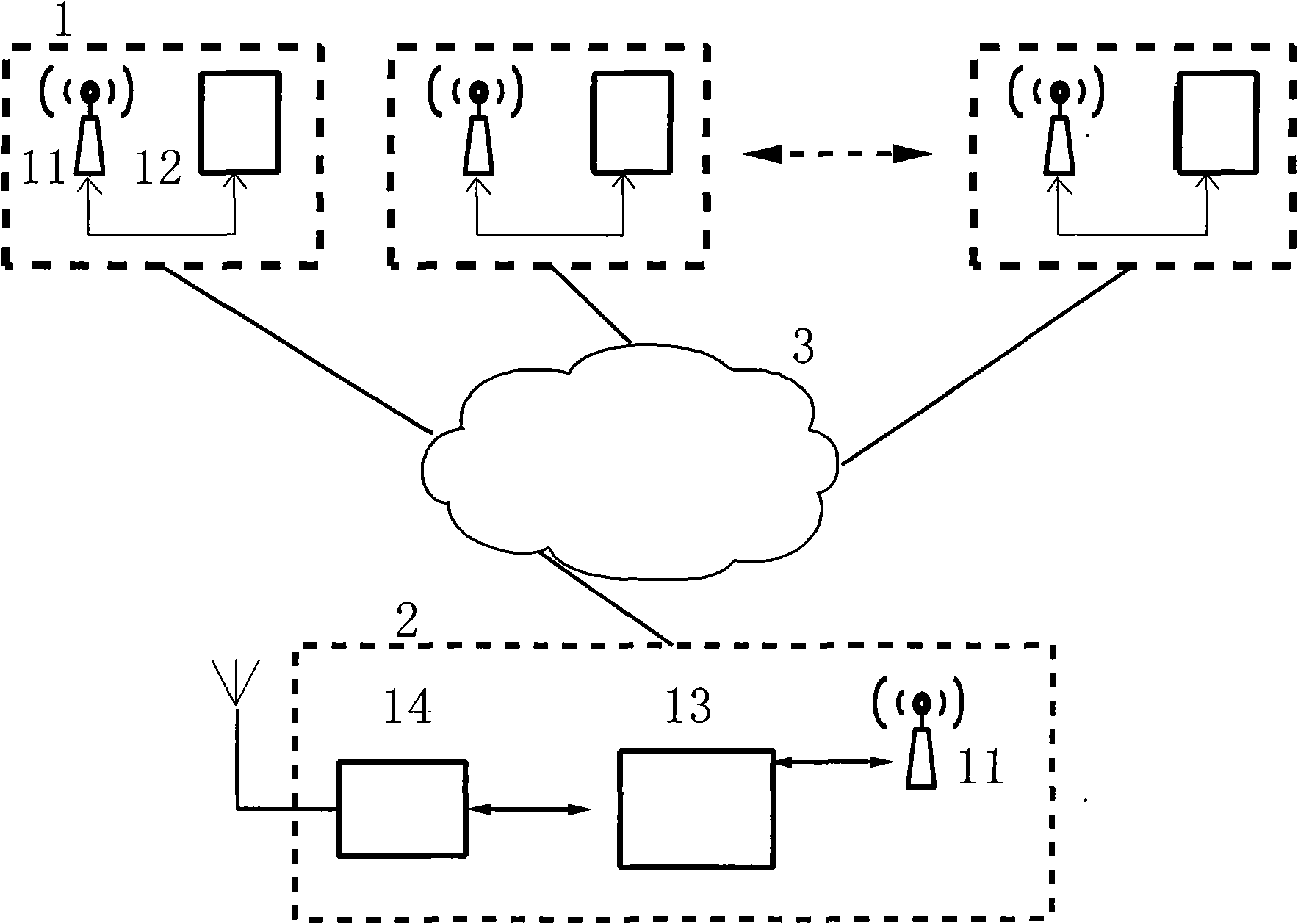

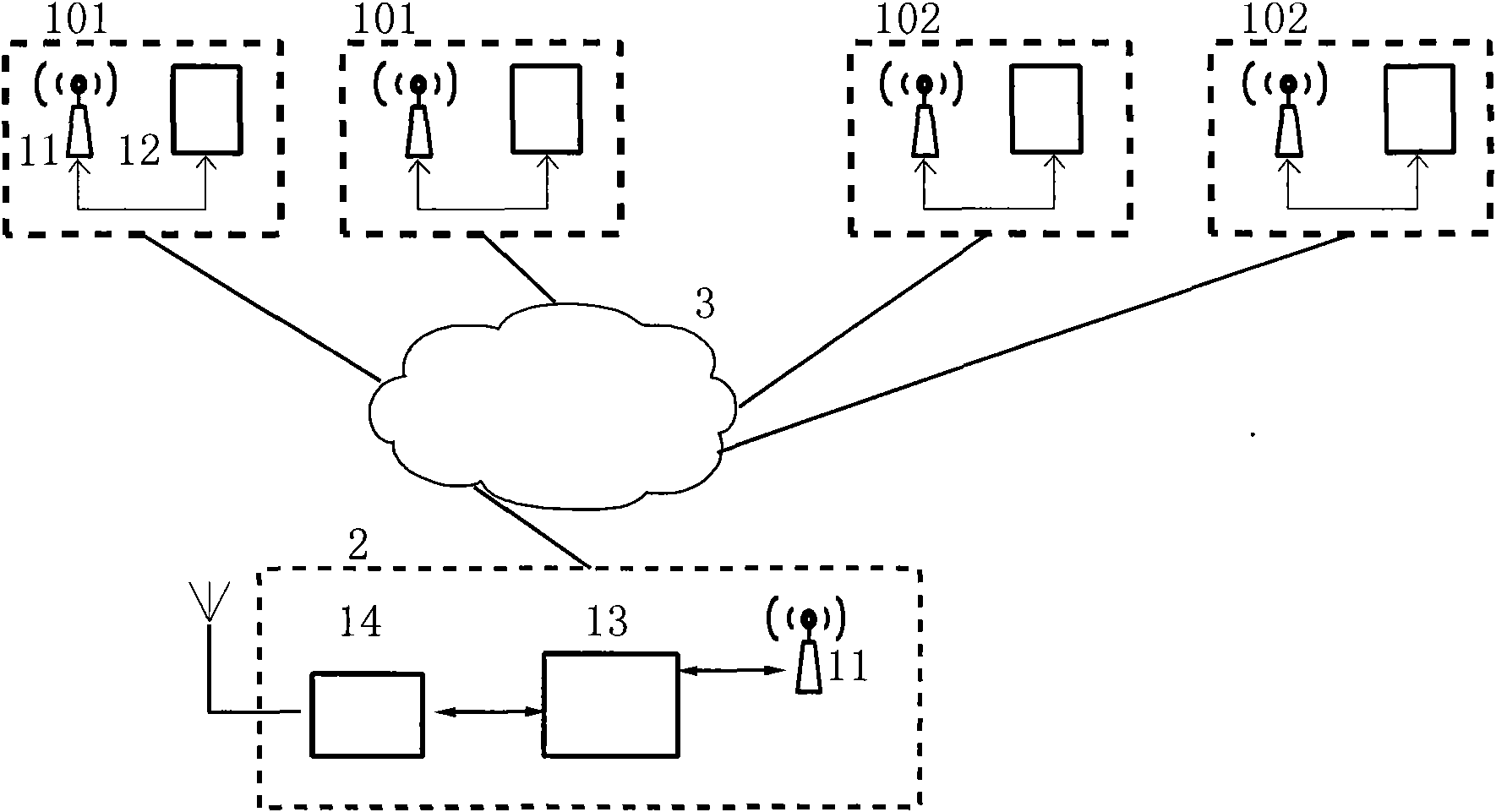

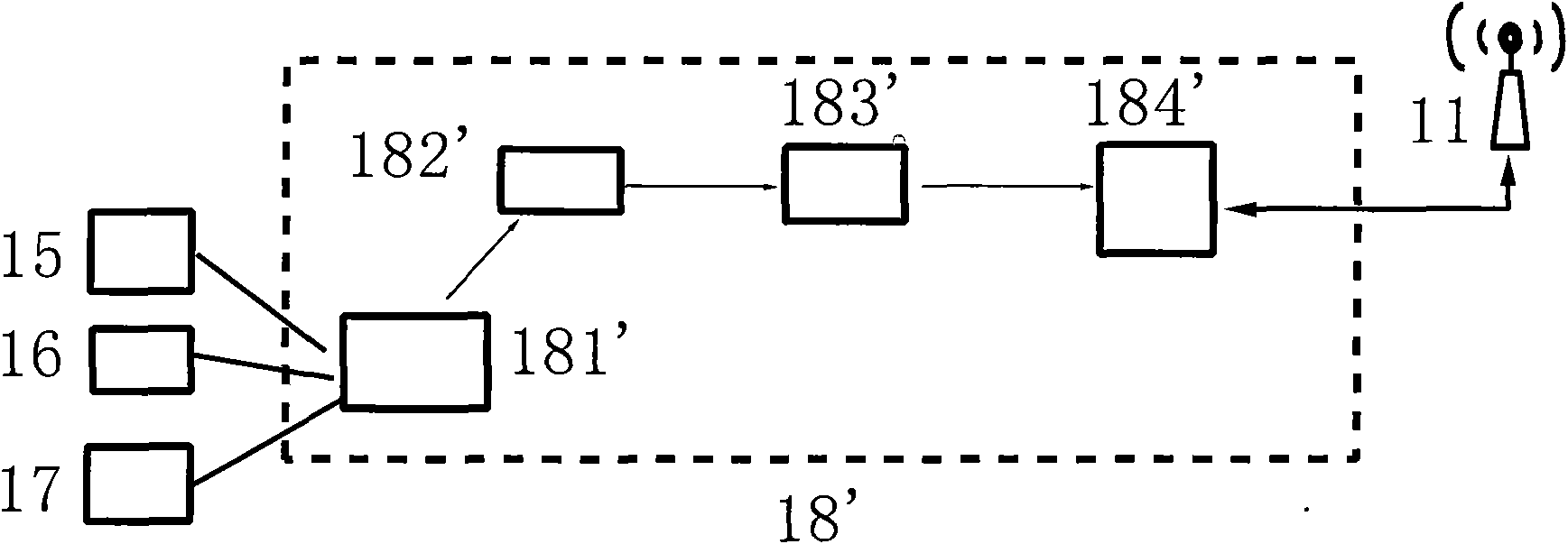

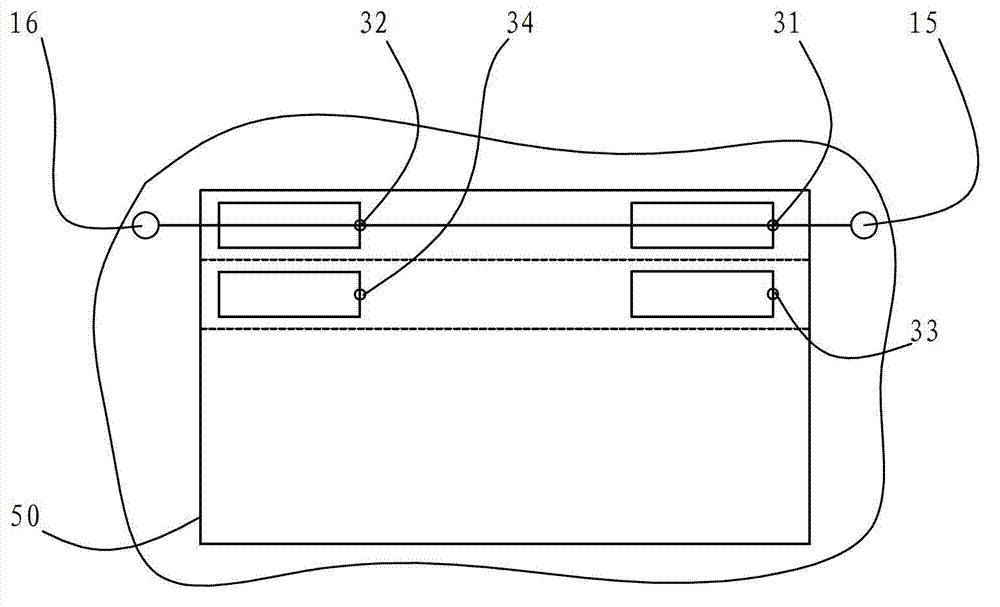

Monitoring and processing system for operating environment of electrical equipment

InactiveCN102072746ASolve long-term water accumulationSolve many problems such as the formation of condensation on the surface of switchgear equipment and easy equipment accidentsTransmission systemsLevel indicators by pressure measurementWork cycleComputer module

The present invention discloses a monitoring and processing system for an operating environment of electrical equipment, which is characterized by comprising at least one detection unit (1) for collecting detection signals and one main control unit (2) for receiving information of a plurality of detection units. The detection units (1) are respectively formed through connection of a detection control module (12) and a short-range wireless communication module (11), the main control unit (2) is formed through connection of a main control module (13), the short-range wireless communication modules (11) and a GSM (global system for mobile communication) communication module (14), and the main control module (13) is respectively connected with the GSM communication module (14) and the short-range wireless communication modules (11); and each detection unit (1) is connected with the main control unit (2) through a short-range wireless communication network (3). When the monitoring and processing system is applied, the service life of cables, switch cabinets and other devices in a power distribution room can be prolonged, accidents, serious waste of labor and materials and the workload can be reduced, and the work cycle can be shortened.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

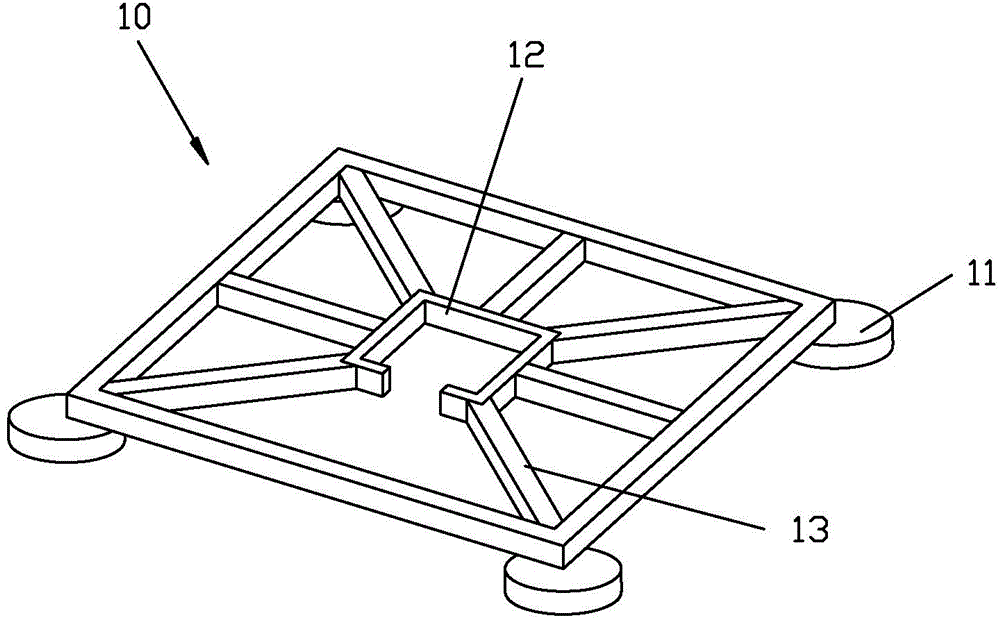

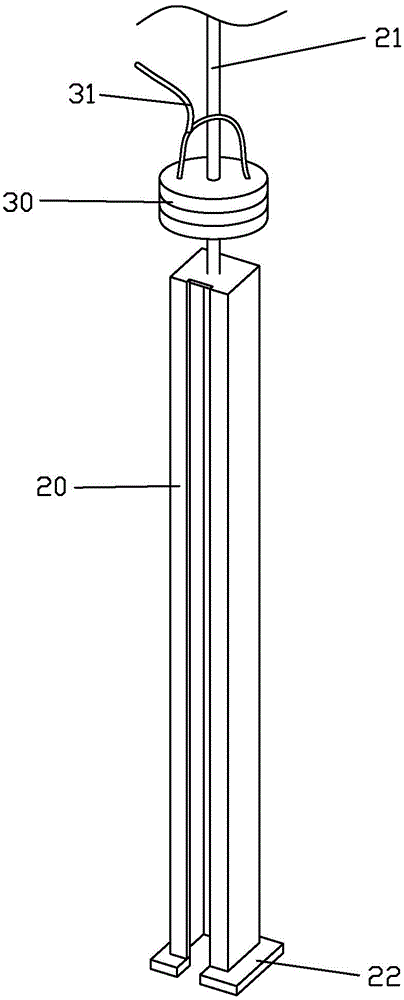

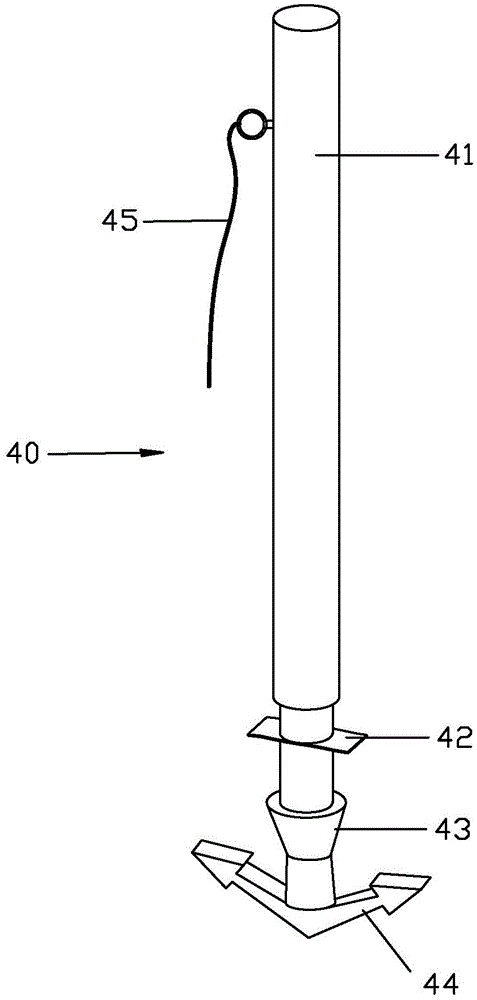

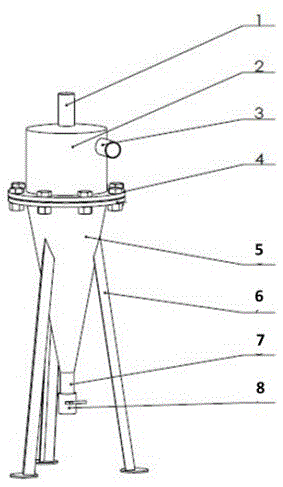

Mooring system embedded in sea bottom

The invention discloses a mooring system embedded in the sea bottom. The mooring system embedded in the sea bottom comprises a stabilization rack, an anchoring bushing, a knocking hammer and an anchor. The stabilization rack is provided with a connection frame, the anchoring bushing is sleeved with the connection frame in a matched mode, and the anchoring bushing is shaped like a barrel and is provided with an opening. The upper end of the anchoring bushing is fixedly connected with a main inhaul cable. The knocking hammer is arranged on the main inhaul cable in a sleeving mode and can move vertically along the main inhaul cable to knock the anchoring bushing. The anchor comprises an anchor body, an anchor bolt capable of being bent downwards, an anchor hammer and an anchor blade capable of being spread outwards. The anchor is connected in the anchoring bushing in a sliding mode through the opening of the anchoring bushing, and the anchor bolt is located below the anchoring bushing. The knocking hammer knocks the anchoring bushing and the anchoring sleeve impacts the anchor bolt, and therefore the anchor bolt can drive the anchor to be thrown into the sea bottom. After the anchoring bushing impacts the anchor bolt for several times, the anchor bolt is bent downwards, the anchoring bushing impacts the anchor hammer to enable the anchor hammer to abut against the anchor blade, and the anchor blade is deformed and spread outwards to make the anchor be fixed at the sea bottom. According to the mooring system embedded in the sea bottom, the mode of embedding an anchor in the surface layer is changed into a deep layer embedding mode that the anchor is embedded into the sea bottom, and therefore the mooring capacity of the anchor is greatly improved.

Owner:FISHERIES RES INST OF FUJIAN

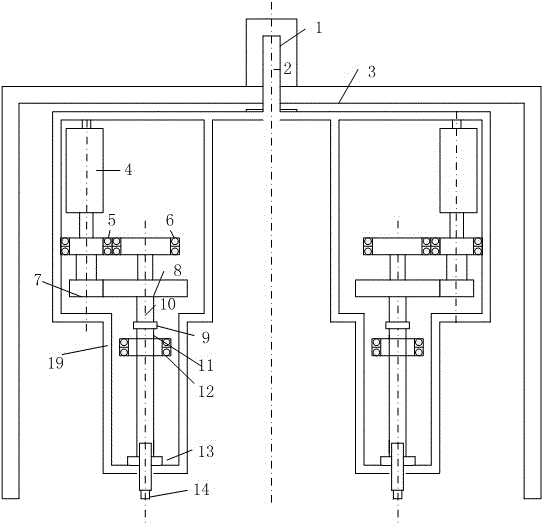

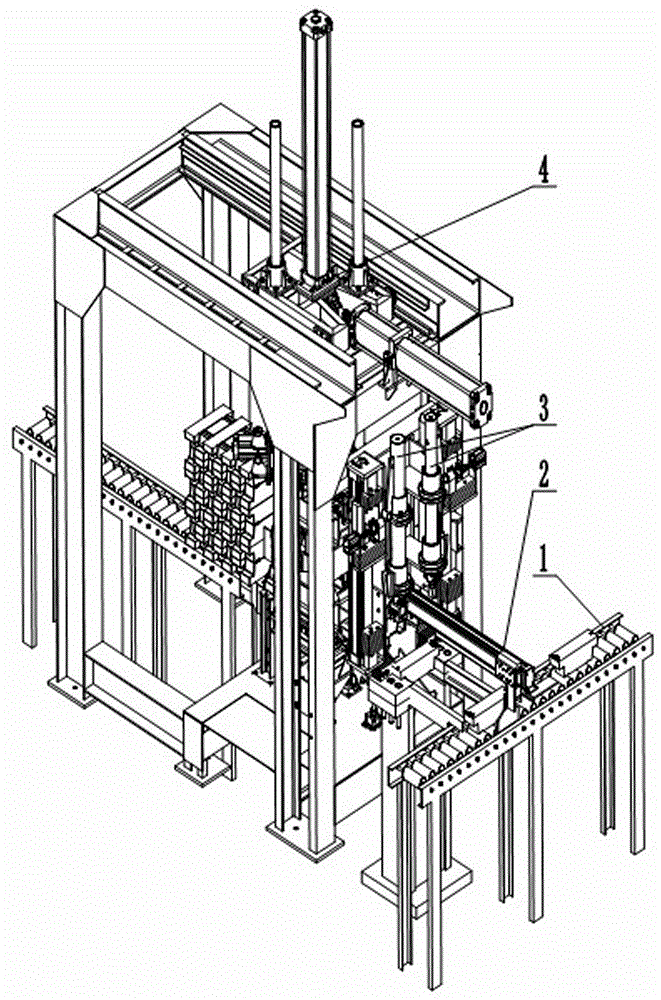

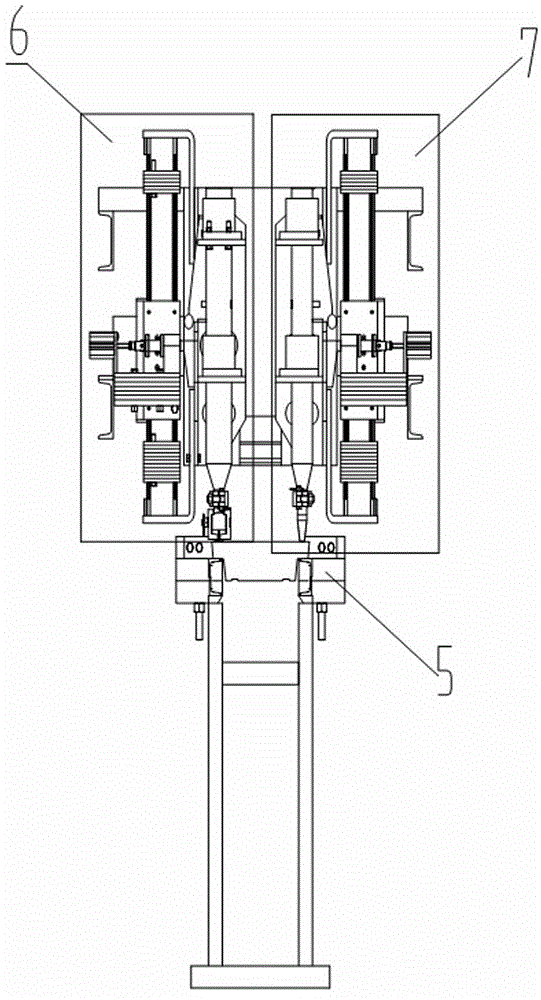

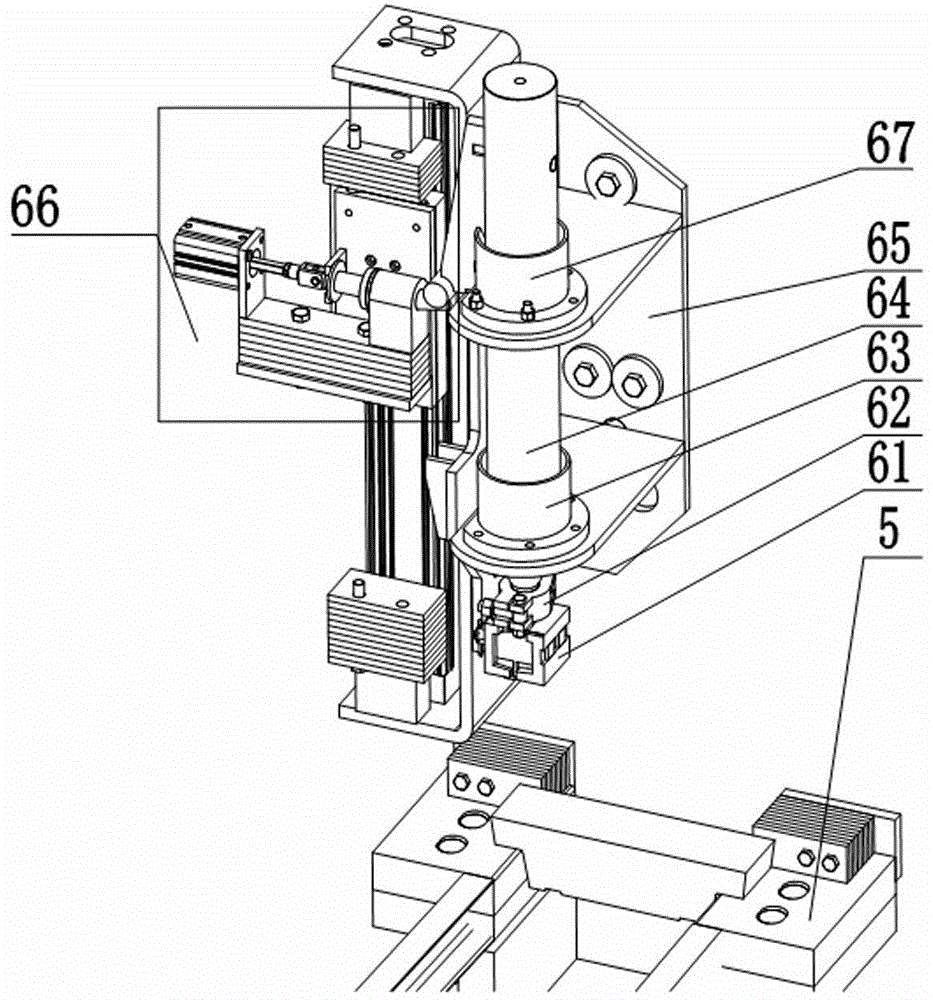

Automatic double-station screw assembly and disassembly mechanism

InactiveCN103331600ASimple structureEasy to processMetal working apparatusEngineeringSymmetric structure

The invention relates to an automatic double-station screw assembly and disassembly mechanism. The mechanism is of a left-right symmetric structure, and comprises a hydraulic device, a piston rod, a machine frame, a station outer frame, a direct-current motor, a first bearing, a second bearing, a driving gear, a driven gear, a large-torque-proof device, a first shaft, a second shaft, a third bearing, a mechanics sensor, a screwdriver head and a third shaft. The automatic double-station screw assembly and disassembly mechanism is economical, durable, reliable, excellent in quality, low in price, simple in structure, easy to machine and manufacture, easy to operate, convenient to maintain, suitable for assembly and disassembly of various screws, high in drilling speed and efficiency, short in operation cycle and low in comprehensive cost.

Owner:SHANGHAI UNIV

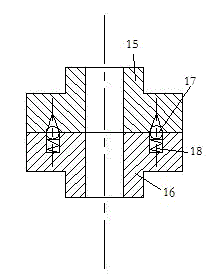

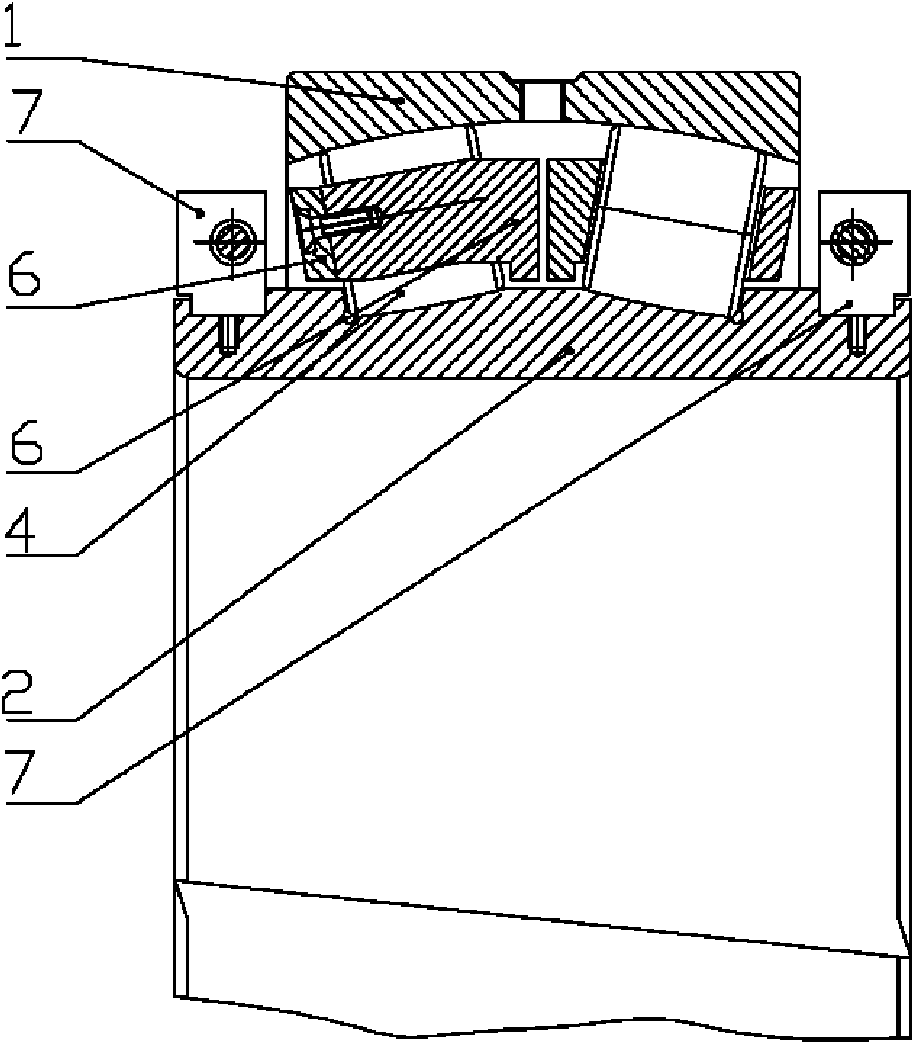

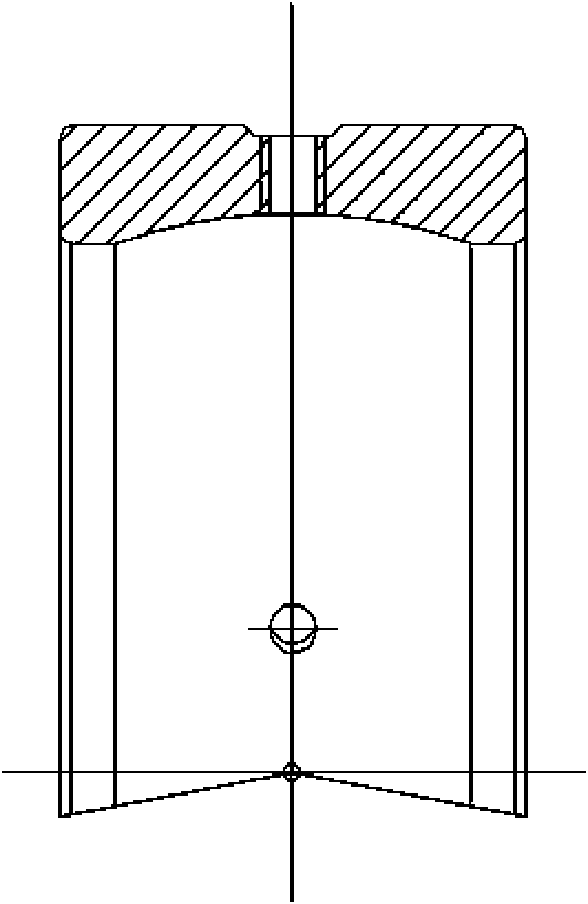

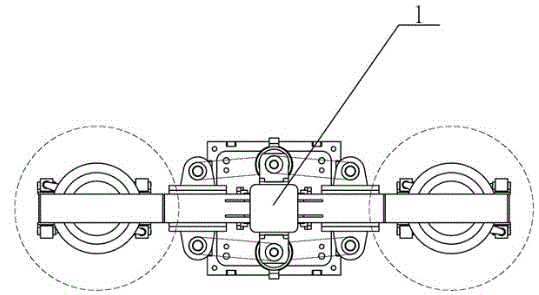

Split spherical roller bearing

InactiveCN101586614AEasy maintenanceEasy to replaceRoller bearingsBearing componentsEngineeringMechanical engineering

The invention discloses a split spherical roller bearing, which is provided with an outer ring (1) and an inner ring (2); a retainer (6) is arranged between the outer ring (1) and the inner ring (2); and the inside of the retainer (6) is provided with two groups of spherical rollers (4). The split spherical roller bearing is characterized in that: the outer ring (1), the inner ring (2) and the retainer (6) all consist of two axially split parts; the outer ring (1) and the inner ring (2) are connected into a whole through a clamp ring (7); and the retainer (6) is connected into a whole through two elastic connecting sheets or U-shaped clamps. Because the structure is split, and the split spherical roller bearing can be radially assembled, and convenient to assemble and disassemble, the split spherical roller bearing shows obvious advantages in the condition that major axes and multi-diameter shafts are assembled, particularly an intermediate journal is smaller than two ends and the like. The mounting, maintenance, and replacement of parts are simple and convenient, the working period is short and the labor amount is less.

Owner:瓦房店第一轧机轴承制造有限公司

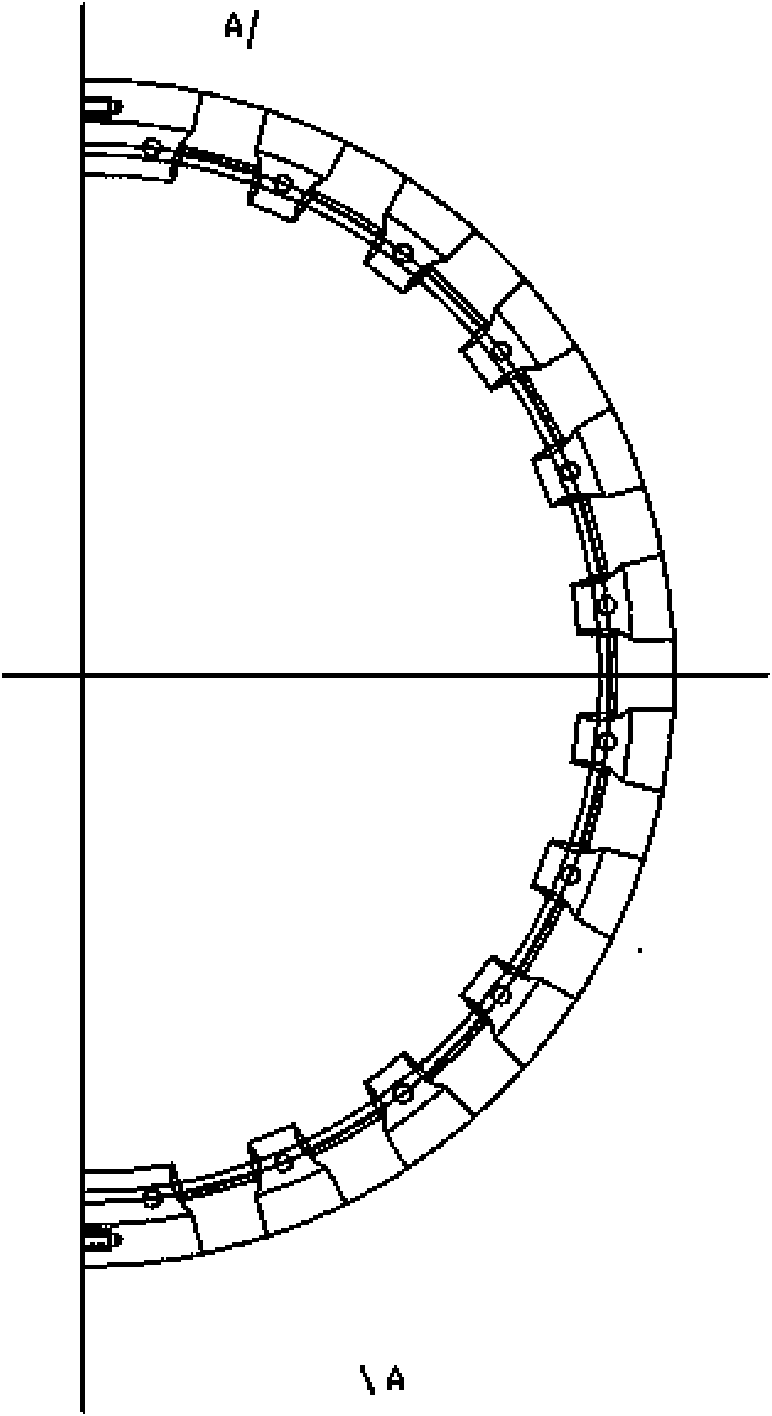

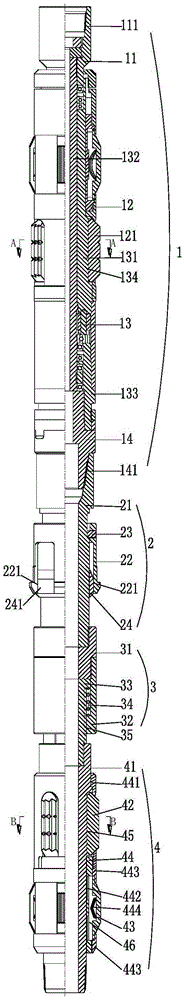

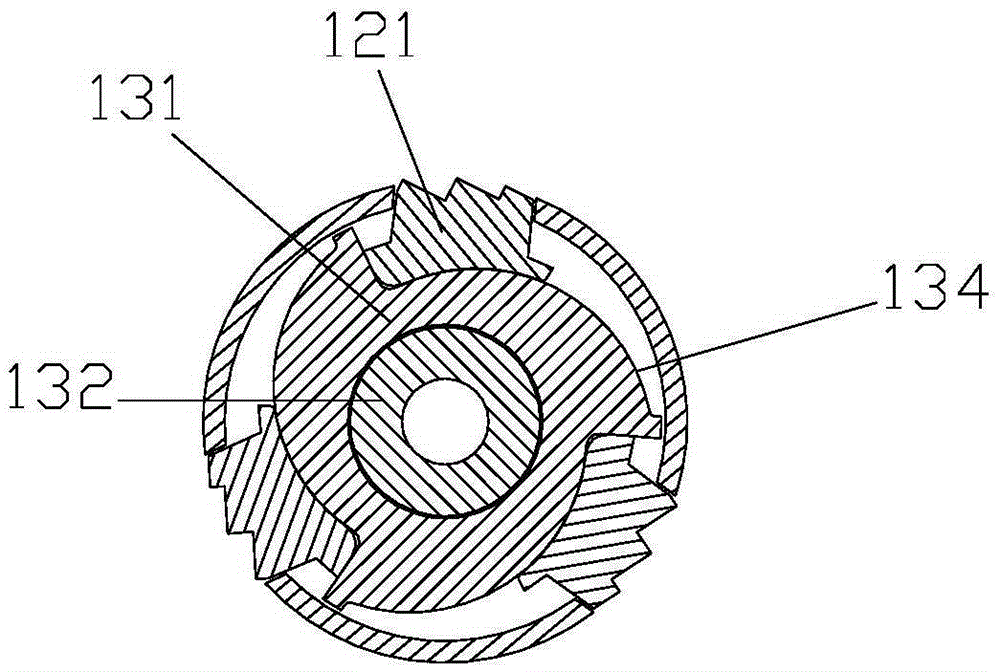

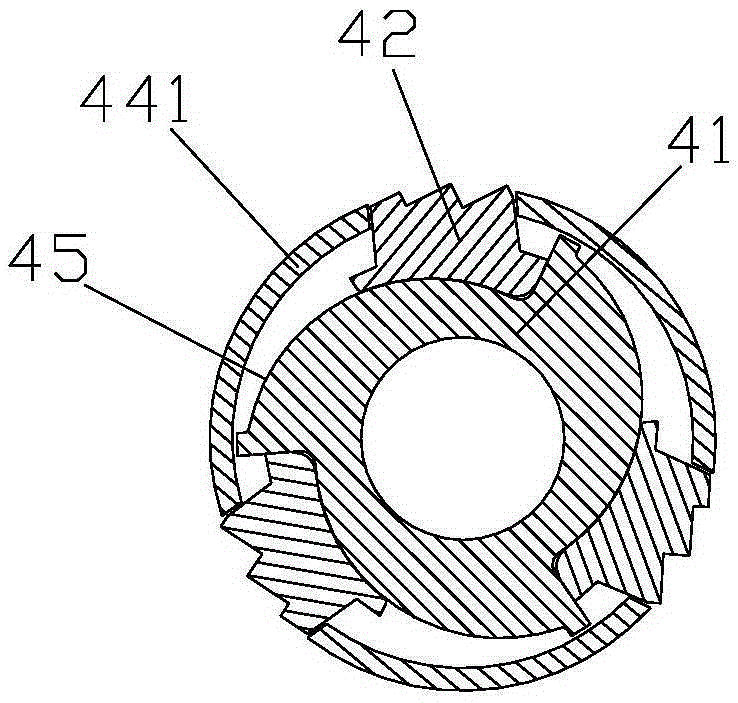

Tool used for taking casing underground at fixed point and using method

ActiveCN105386736AHumanized structure designSimple preparation processBorehole/well accessoriesOil fieldReducer

The invention discloses a tool used for taking a casing underground at a fixed point and a using method, belongs to the technical field of a process of taking the casing underground, relates to the tool for taking the casing underground in an oil field and the using method, in particular to the tool used for taking the casing underground at the fixed point and the using method. The tool solves the problem that the casting cannot be taken at the fixed point due to insufficient torque in a construction process, is simple to operate and accurate in positioning. The tool comprises a planetary reducer, a collar locator, a compensator and an anchoring device, which are in threaded connection from top to bottom in sequence. The using method comprises the following steps: step I, feeding the tool used for taking the casing underground at the fixed point into a predetermined depth which needs replacing the casing by virtue of a ground workover operating vehicle; step II, determining a casing collar position; step III, lifting a tubular column to reach load for replacing the casting; and step IV, pulling out the tool used for taking the casing underground at the fixed point and the replaced casing.

Owner:PANJIN YONGSHENGLI PETROLEUM TECH DEV

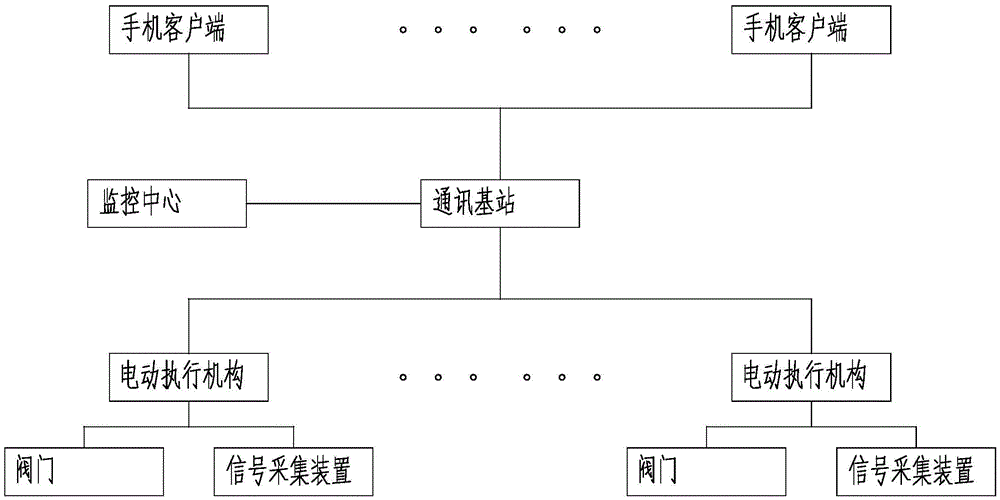

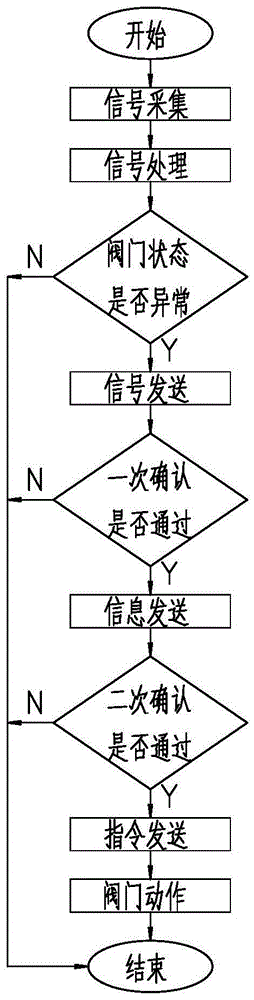

Intelligent valve remote control system and working method thereof

ActiveCN105570512ARealize joint operationLarge transmission distanceOperating means/releasing devices for valvesControl systemRemote control

The invention discloses an intelligent valve remote control system and a working method thereof and relates to the field of remote control of valves. The invention provides the intelligent valve remote control system and the working method thereof, which are smart in structure, low in operation difficulty and low in cost, and can timely find out and feed back abnormal conditions of a valve in use, so that people can quickly make a judgment and timely give commands to electric execution mechanisms. The electric execution mechanisms are used for driving the valve and communicate with a signal collecting device, a monitoring center communicates with a telecommunication base station by wireless information, a plurality of mobile phone clients communicate with the telecommunication base station by the wireless information, a plurality of the electric execution mechanisms communicate with the telecommunication base station by the wireless information, and the electric execution mechanisms are in one-to-one correspondence to the mobile phone clients. The system and the method have the characteristics of being wide in transmission scope, convenient in communication, simple to use, easy to popularize and the like.

Owner:YANGZHOU ELECTRIC POWER EQUIP MFG FACTORY CO LTD

Tire post-inflation apparatus having novel transmission structure

Owner:SINO ARP TIRES EQUIP TECH (SUZHOU) CO LTD

Underwater silt remover, underwater silt removing device comprising the same and operation method thereof

ActiveCN103088861AEven and thorough cleaningCompact and lightweightMechanical machines/dredgersSiltSludge

Provided are an underwater silt remover, an underwater silt removing device comprising the same and an operation method thereof. The underwater silt remover comprises a collecting bin arranged in a machine frame, an inlet of a sludge pump is communicated with the collecting bin, an outlet of the sludge pump is communicated with a sludge outlet pipe, a stirring blending mechanism is further arranged in the machine frame, the stirring blending mechanism comprises a rotary blade with a ridging function and a diving motor used for driving the rotary blade to rotate, a filtering net is arranged on the collecting bin, and the rotary blade is located in the front of the collecting bin. Power for driving the underwater silt remover to move forwards in sludge is from traction force of a first winch. The traction force is output to the first elastic balancer, a spring of the first elastic balancer is stretched to perform conversion storage of energy, then in the process of silt removing work of the underwater silt remover, the spring of the first elastic balancer slowly retracts to the original shape, releases stored energy, and supplies the power to the underwater silt remover for moving forwards.

Owner:枣庄高新区立正建筑工程有限公司

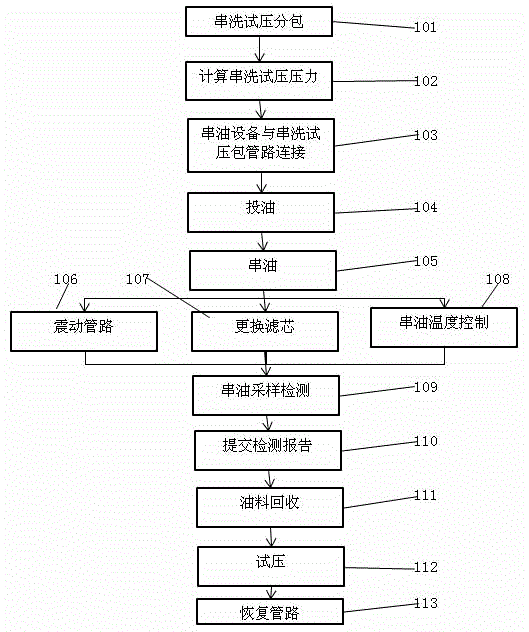

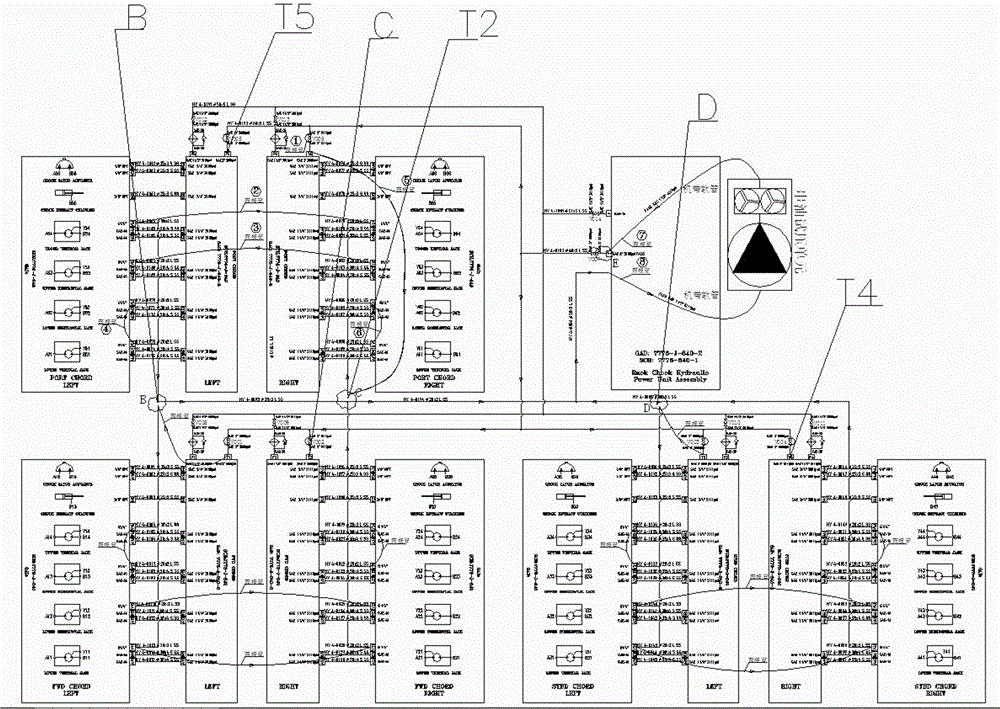

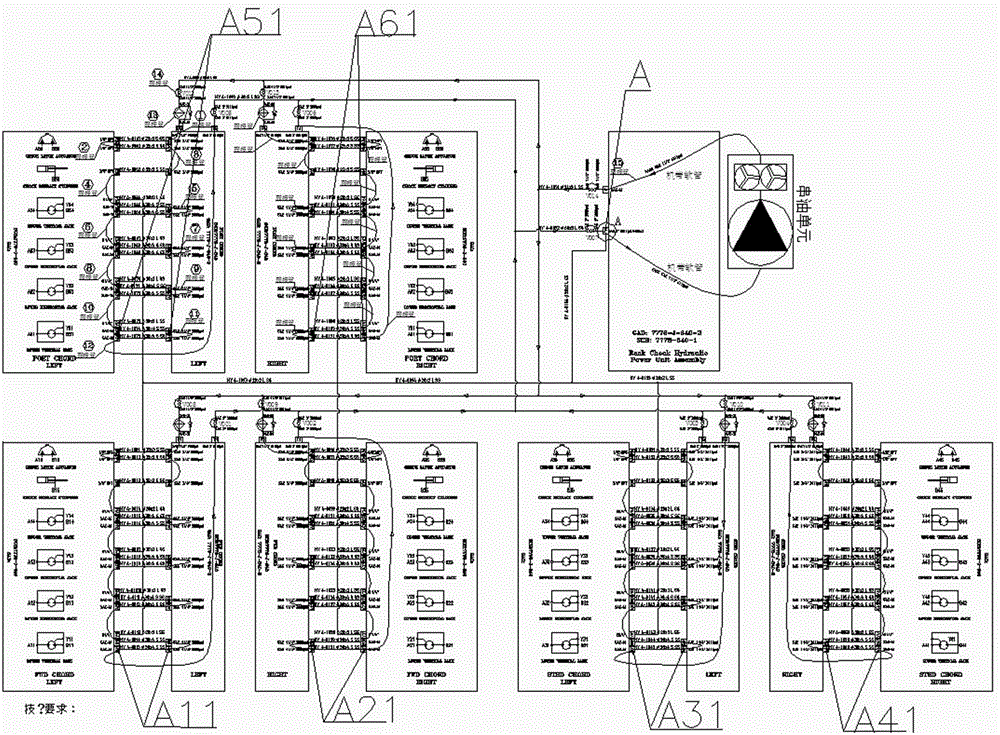

One-stop flushing and pressure testing method of hydraulic system of self-elevating drilling platform

ActiveCN104533888AReduce repetitive disassembly workShorten the working cycleFluid-pressure actuator testingFluid-pressure actuator componentsEngineeringDual purpose

The invention relates to a one-stop flushing and pressure testing method of a hydraulic system of a self-elevating drilling platform. The method is to use dual-purpose oil intermingle equipment for performing the oil intermingle flushing for the hydraulic system; after the flushing, a pressure testing pump is started to finish the pressure testing operation of the hydraulic system; and the dual-purpose oil intermingle equipment is flushing dual-purpose Aldgate FTE-800 equipment. The flushing and pressure testing method comprises the specific steps of subpackaging flushing and pressure testing; calculating flushing and pressure testing pressure; connecting pipelines between the oil intermingle equipment and the flushing and pressure testing package; filling oil; intermingling oil, wherein in the oil intermingle process, a pipeline is required to be shaken, a filter element is required to be replaced, and the oil intermingle temperature is kept lower than 65 DEG C; performing oil intermingle sampling detection; submitting an examining report after the detection is qualified; recovering oil; performing pressure testing; and recovering the pipeline after the pressure testing is finished. The flushing and pressure testing method has the following advantages: the flushing and pressure testing method adopts the dual-purpose oil intermingle equipment, so that the flushing and pressure testing method is simpler and safer, reduces the repeated disassembly operation of the pipeline of the hydraulic system, and shortens the working period.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

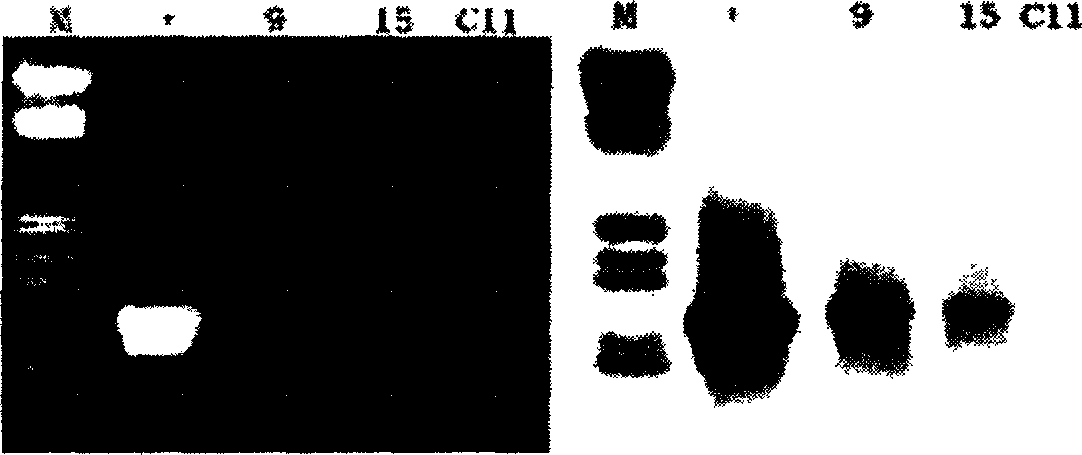

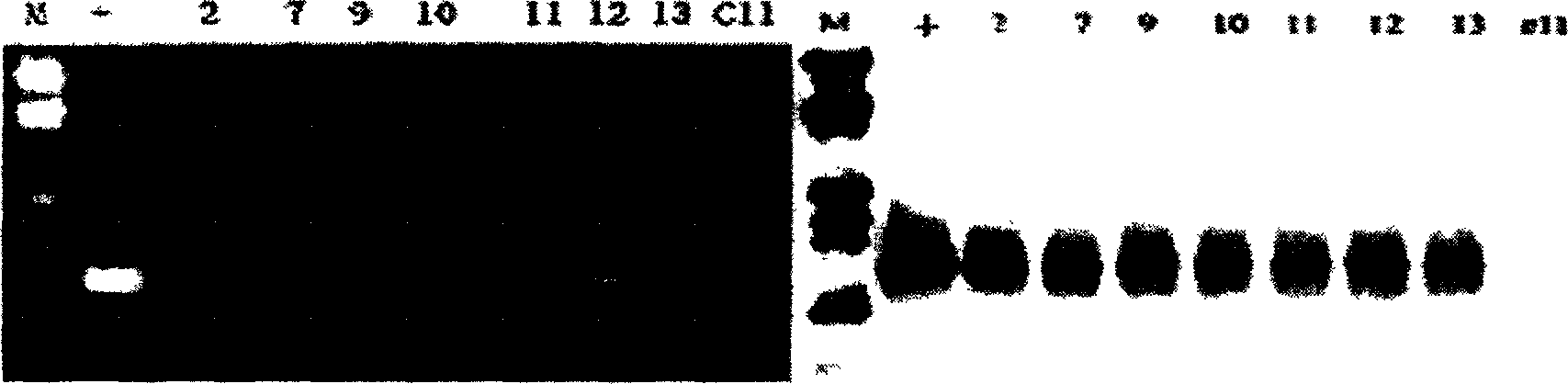

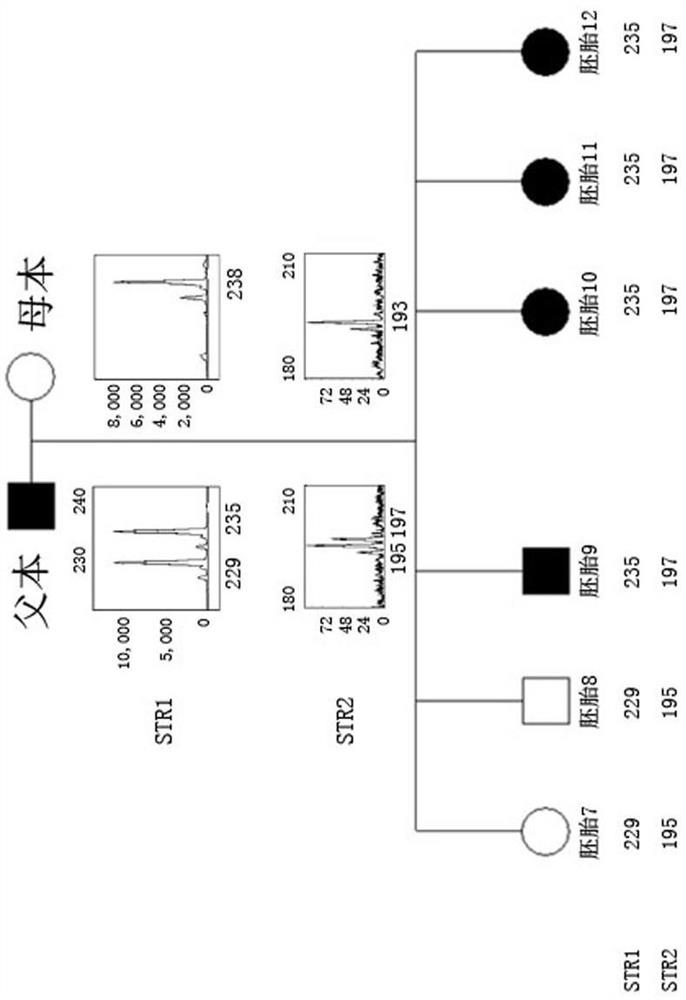

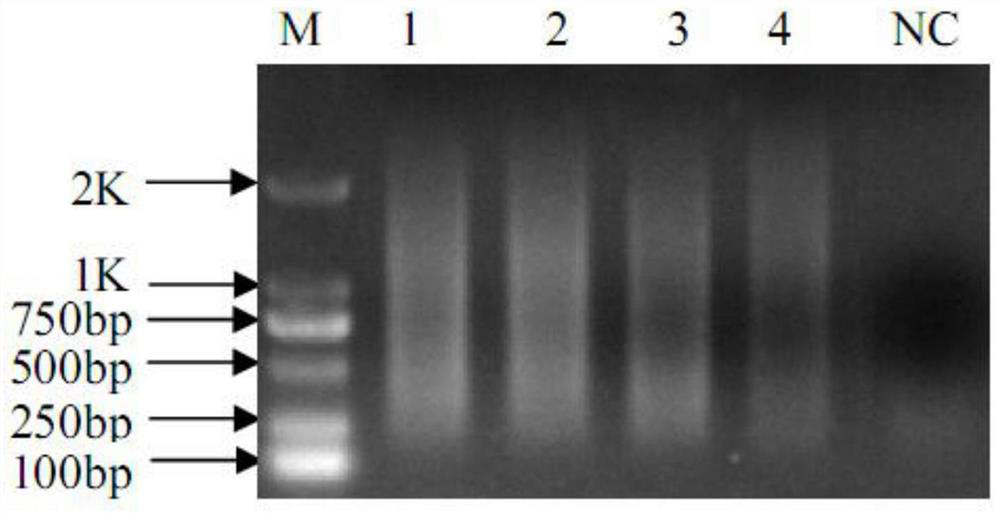

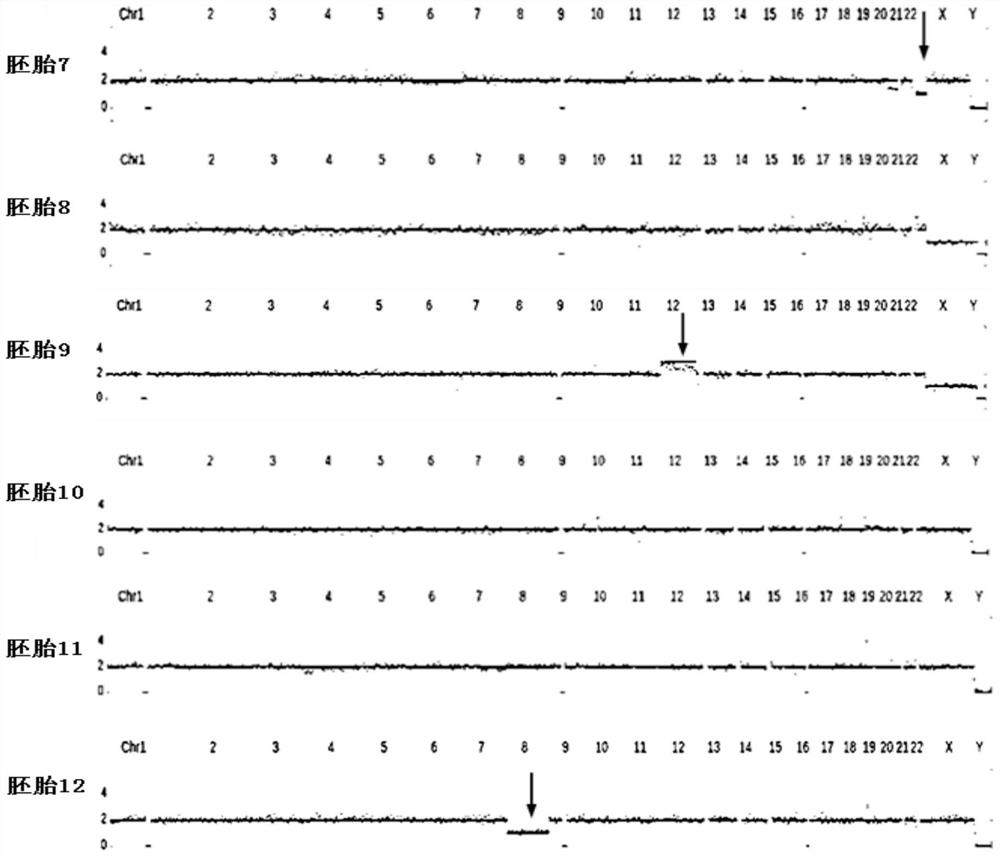

A method for simultaneous gene locus, chromosome and linkage analysis

ActiveCN105543339BEasy to operateStrong practical feasibilityMicrobiological testing/measurementRecurrent miscarriageChromosomal disorder

The invention relates to a method for simultaneously completing gene loci, chromosomes and linkage analysis, specifically including the acquisition of embryonic cell samples, whole genome amplification, target gene mutation site amplification, whole genome amplification products and target gene mutation sites The main steps of database construction, high-throughput sequencing and data analysis, through the use of whole genome amplification technology combined with high-throughput sequencing, multiple comprehensive tests can be completed in one step, avoiding the use of multiple methods and steps for single-gene genetic diseases Detection of mutation sites, chromosomal disorders and linkage analysis. The method provided by the present invention provides favorable conditions for micro-sample, not only can be used for PGD detection to determine whether the embryo carries a disease-causing gene and abnormal chromosome copy number; it is also suitable for genetic screening of embryos of recurrent miscarriages and elderly women, realizing a Steps to complete multiple detections of a single sample. Because of its simple operation, short period and strong feasibility, it is beneficial to popularization and application.

Owner:SHANGHAI XUKANG MEDICAL TECH CO LTD +2

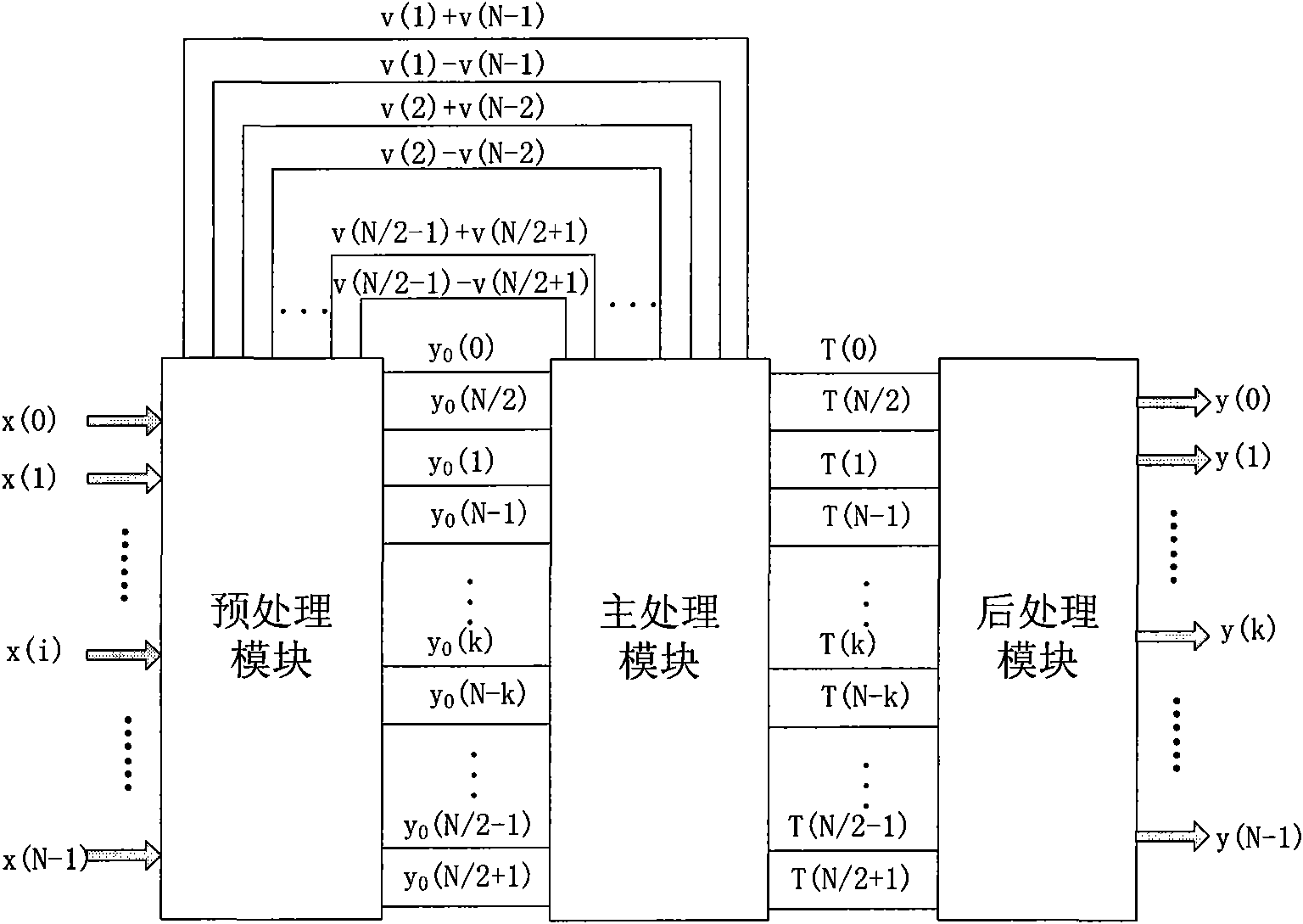

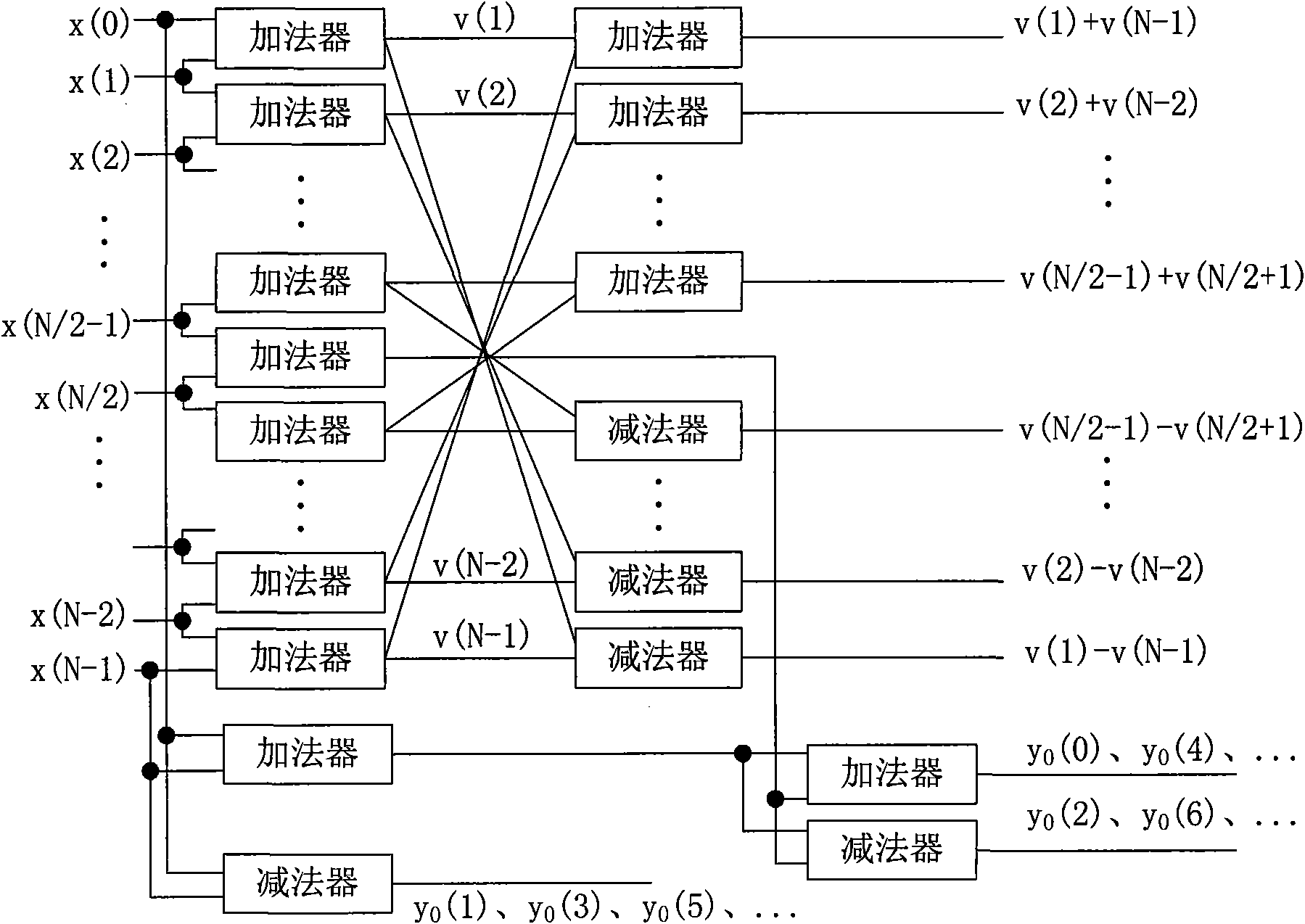

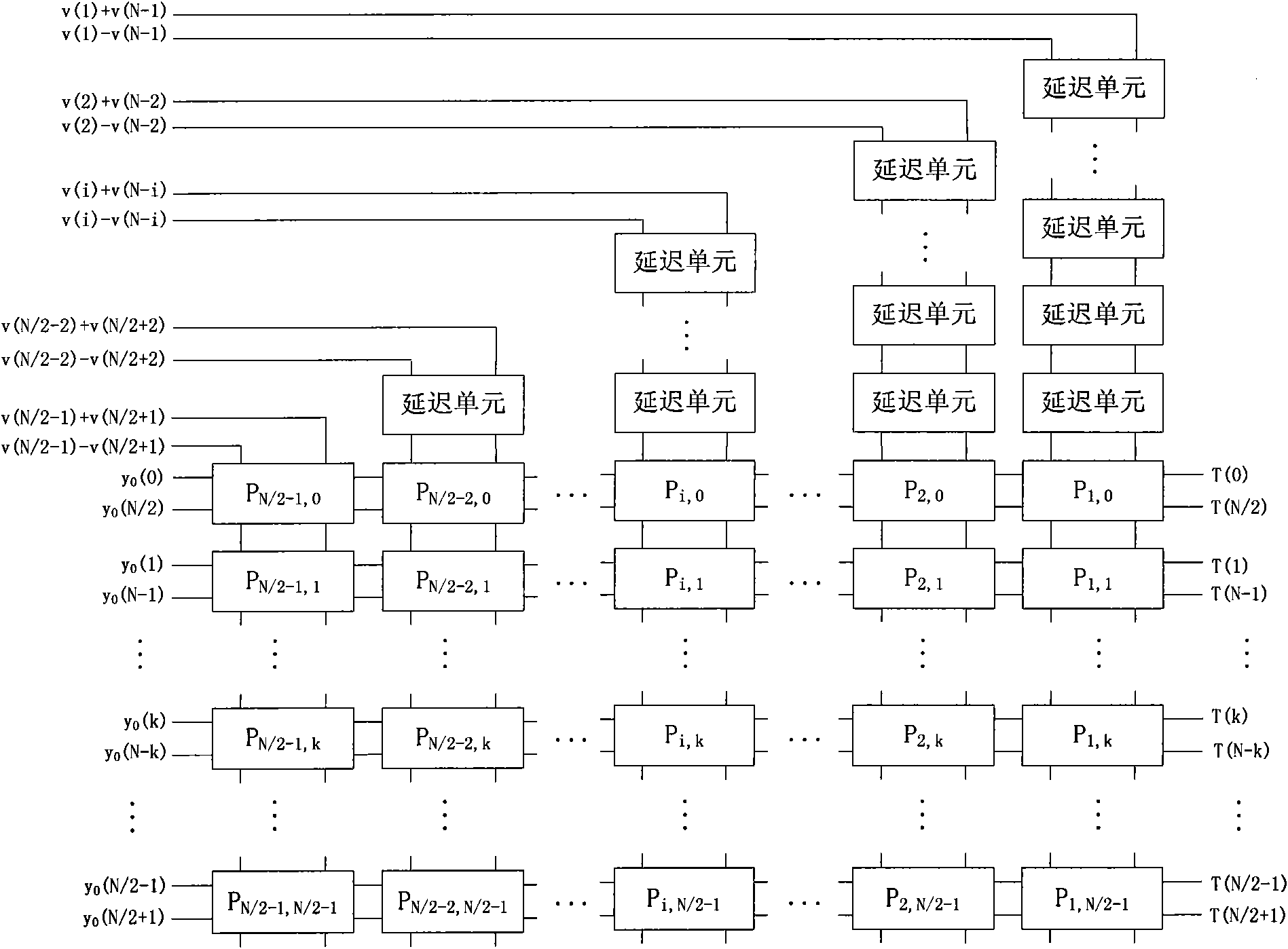

Method and device for processing discrete cosine transform

InactiveCN101634981ASimple structureImprove throughputComplex mathematical operationsSystolic arrayTime complexity

The invention discloses a method and a device for processing discrete cosine transform. The method for processing discrete cosine transform provides a device which corresponds to the method on the basis of the formula modification of a discrete cosine transform algorithm. The device forms a flow line structure by a preprocessing module, a main processing module and a post processing module. A main processing unit adopts a systolic array structure comprising a delay unit and an operation unit. The whole structure realizes higher parallelism and lower area-time complexity by the improvement of the algorithm and an idea of a systolic array. The invention can be applied in the fields of image signal processing, communication, and the like, particularly the internationally public coding standard, such as JPEG, MPEG, H26x, and the like.

Owner:ZHEJIANG UNIV

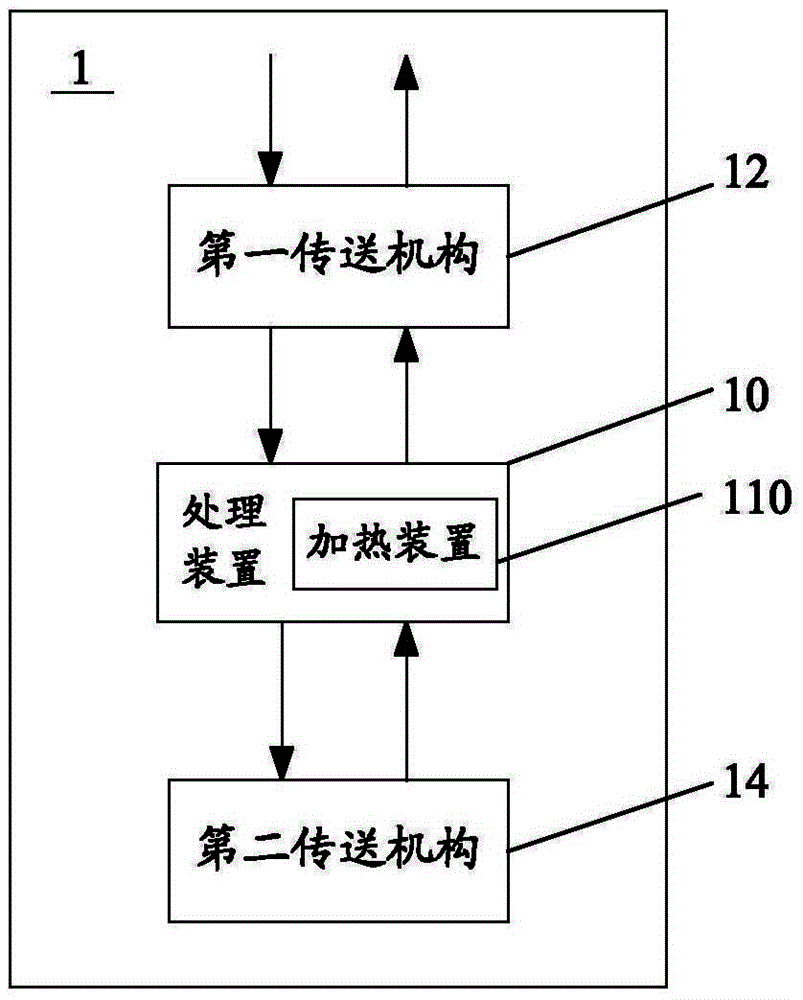

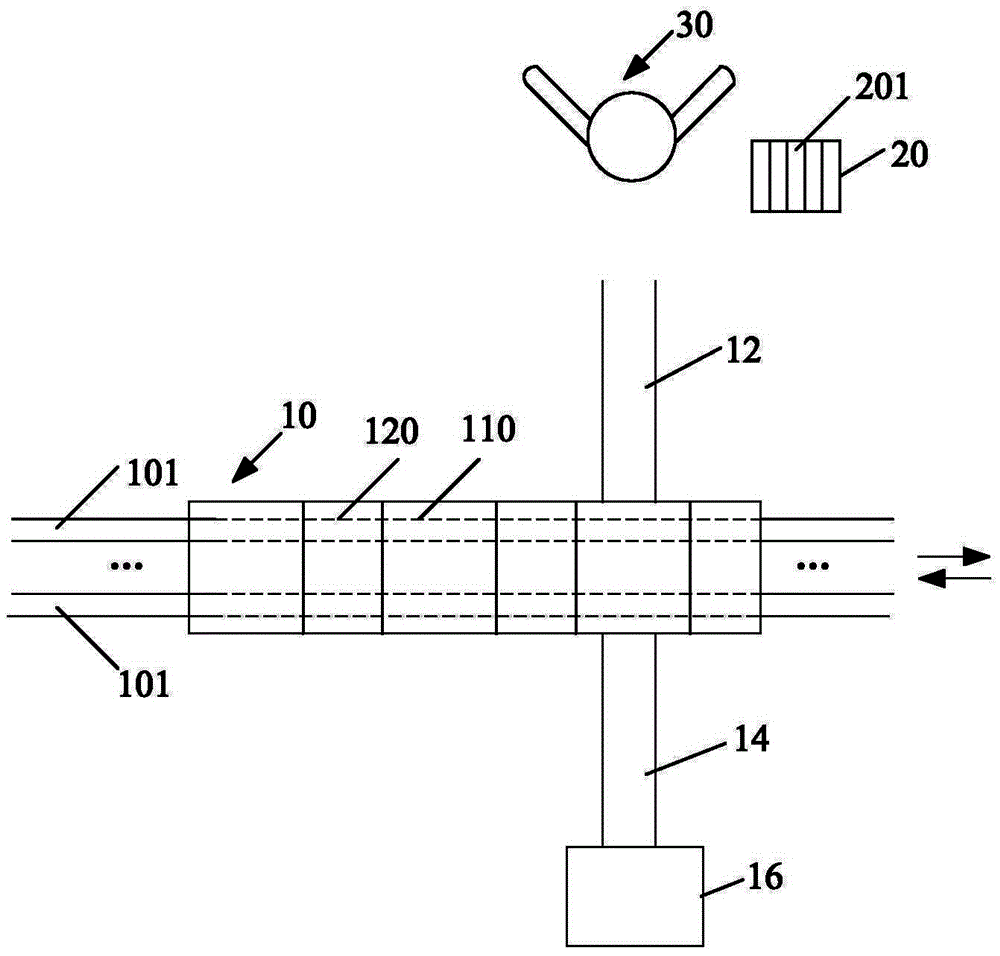

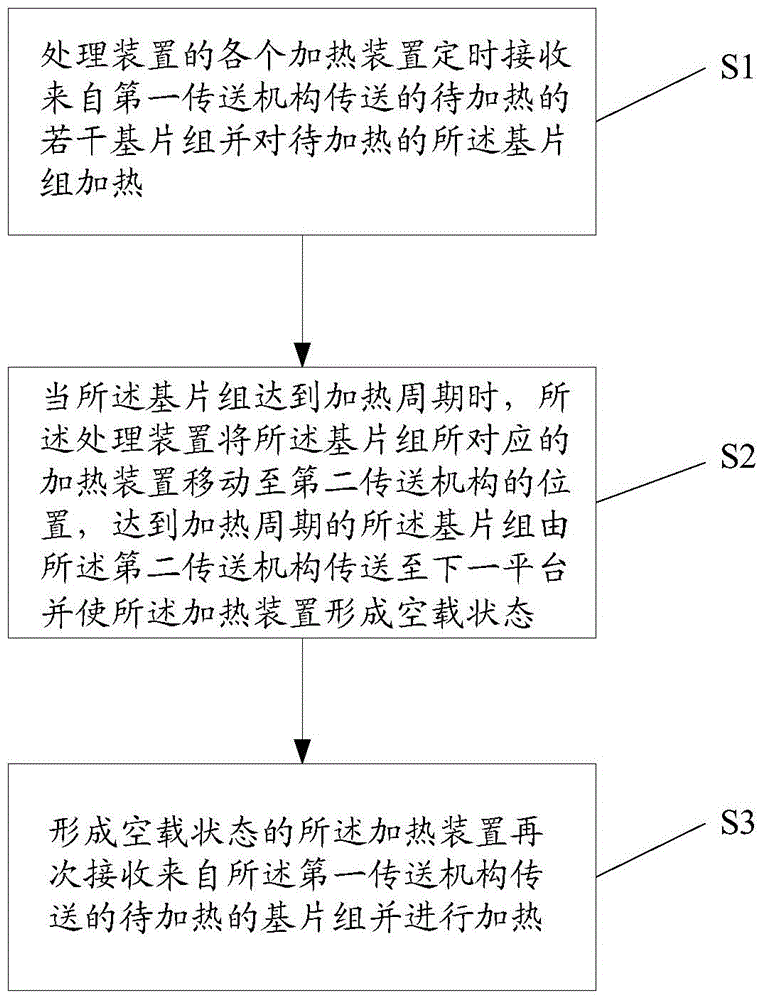

Substrate processing control equipment and control method

InactiveCN104157596AShort duty cycleImprove work efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingHeating cycleControl equipment

The invention discloses substrate processing control equipment, which comprises a processing device and a first transmission mechanism and a second transmission mechanism respectively connected with the processing device. The first transmission mechanism is used for transmitting a to-be-heated substrate group to the processing device; the processing device comprises a plurality of heating devices, each heating device is used for receiving the to-be-heated substrate group regularly and carrying out heating, the processing device moves the heating device corresponding to the substrate group reaching the heating cycle to the position of the second transmission mechanism, and the heating device in an empty-loading state receives the next to-be-heated substrate group and carries out heating; and the second transmission mechanism is used for transmitting the substrate group reaching the heating cycle to a next platform. According to the method, multiple to-be-heated substrate groups can be heated at the same time in one heating cycle, the heating cycle of each substrate is greatly shortened, and the working efficiency is greatly improved. The invention also discloses a substrate processing control method.

Owner:熊丹

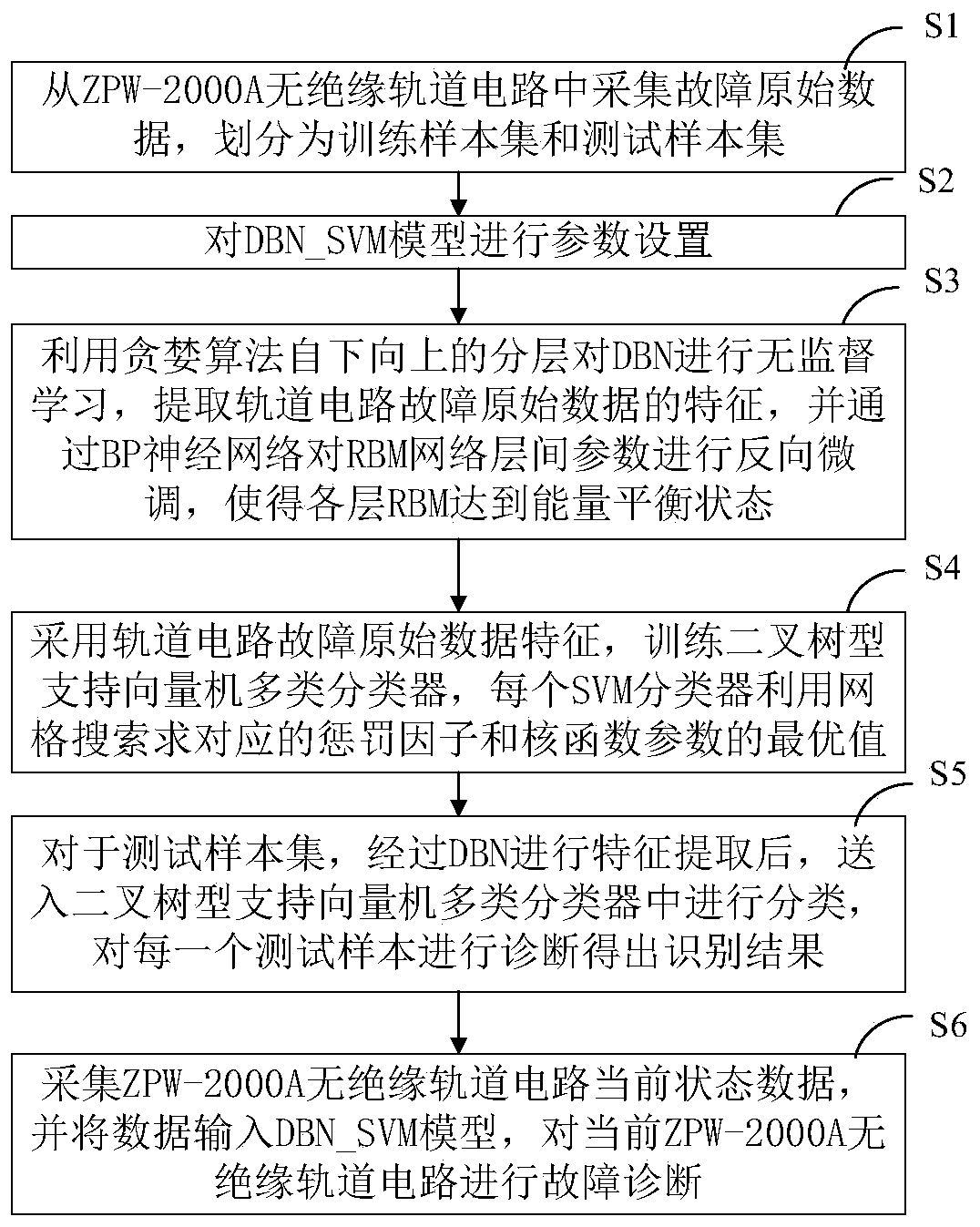

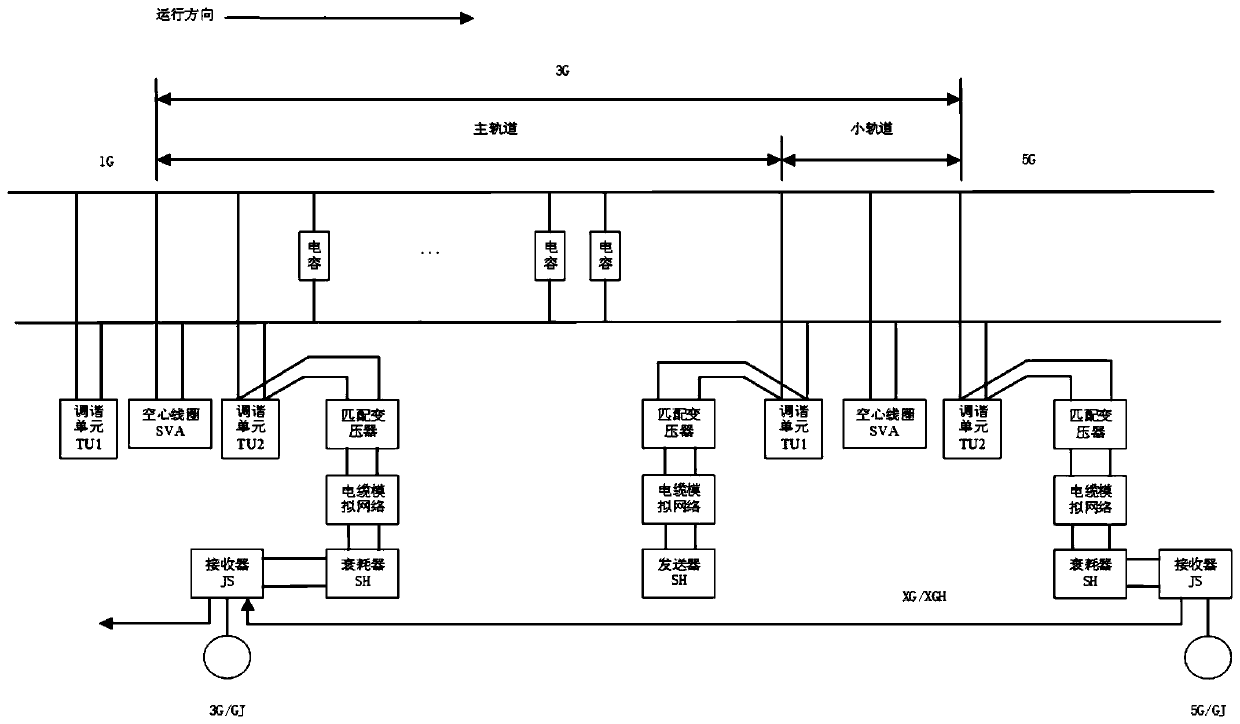

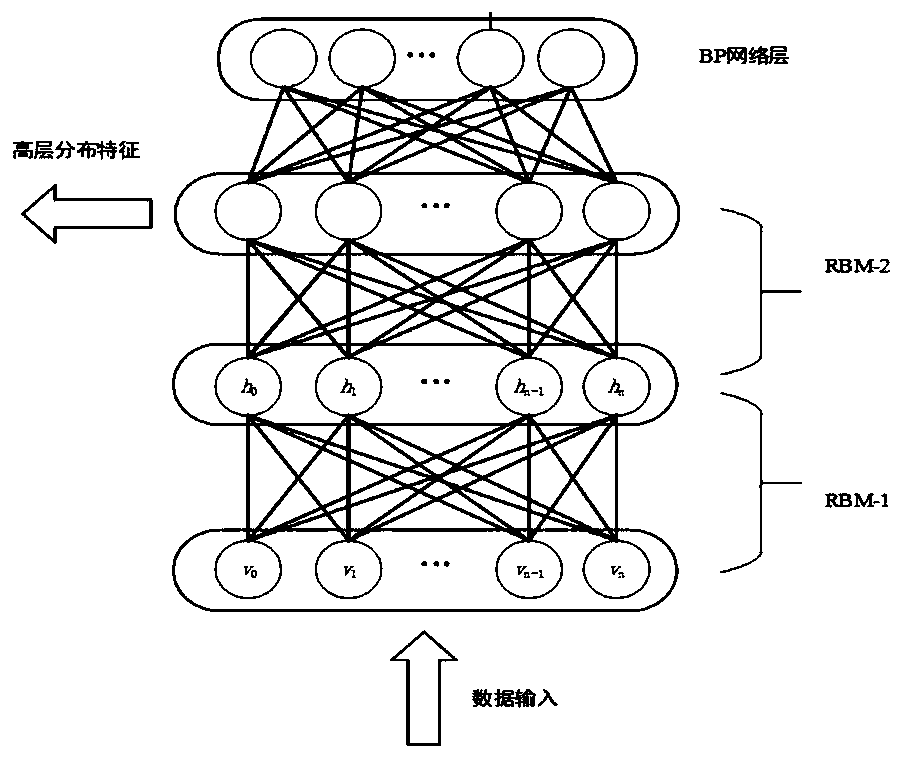

ZPW-2000A type uninsulated track circuit fault diagnosis method

ActiveCN110852365AImprove fault diagnosis efficiencyStable diagnostic performanceCharacter and pattern recognitionNeural learning methodsData ingestionTest sample

The invention provides a ZPW-2000A type uninsulated track circuit fault diagnosis method based on a DBM-SVM. The ZPW-2000A type uninsulated track circuit fault diagnosis method based on the DBM-SVM isused for solving the problems of randomness, low diagnosis precision, large error and long period of manual detection. The diagnosis method comprises the following steps: dividing original data intoa training sample set and a test sample set; taking training sample set data as input data of the DBN; extracting features of track circuit fault original data, training a binary tree type support vector machine multi-class classifier by adopting the extracted features of the track circuit fault original data, and sending a test sample set into the binary tree type support vector machine multi-class classifier for classification to obtain a diagnosis result. According to the invention, based on the DBM-SVM model, fault diagnosis is carried out on the ZPW-2000A uninsulated track circuit, the diagnosis performance is stable, the precision is high, the error is small, the work period is short, and the fault diagnosis efficiency of the uninsulated track circuit is improved.

Owner:BEIJING JIAOTONG UNIV

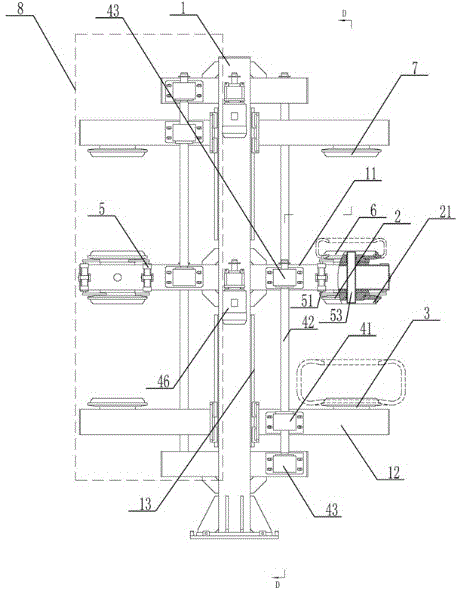

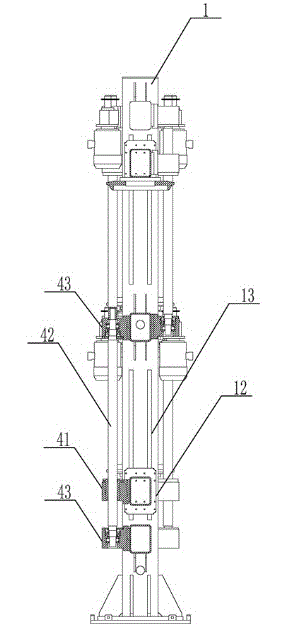

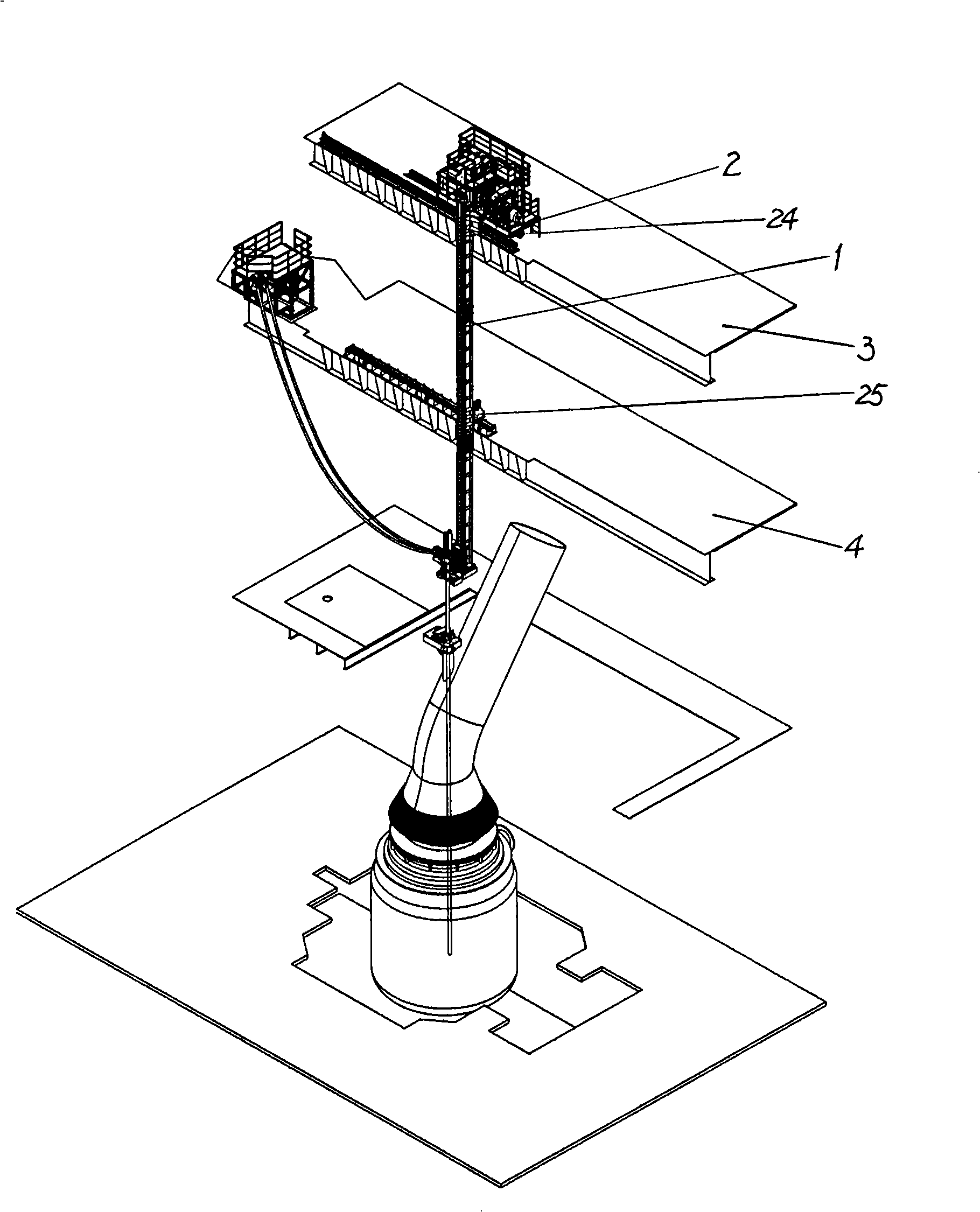

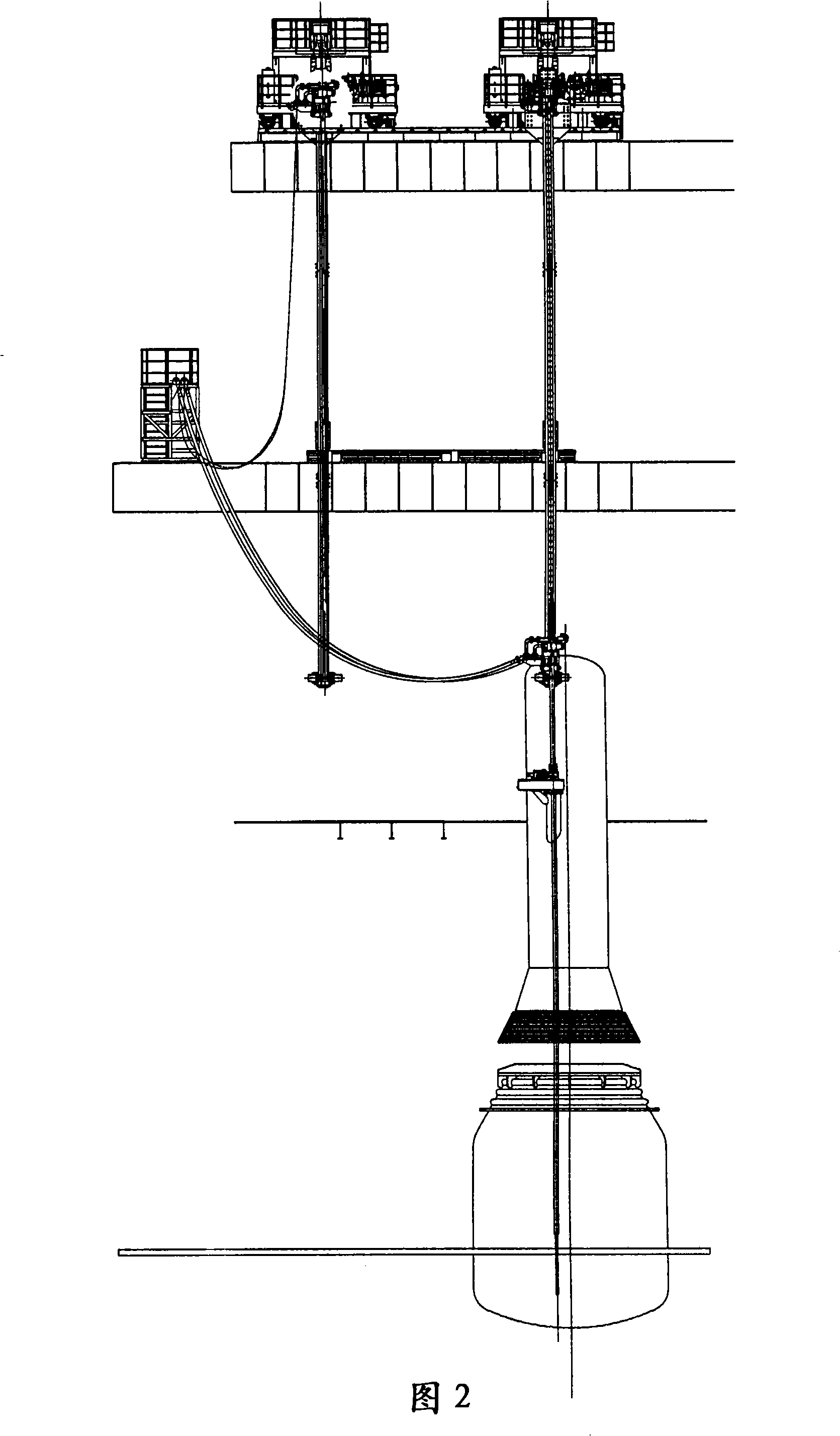

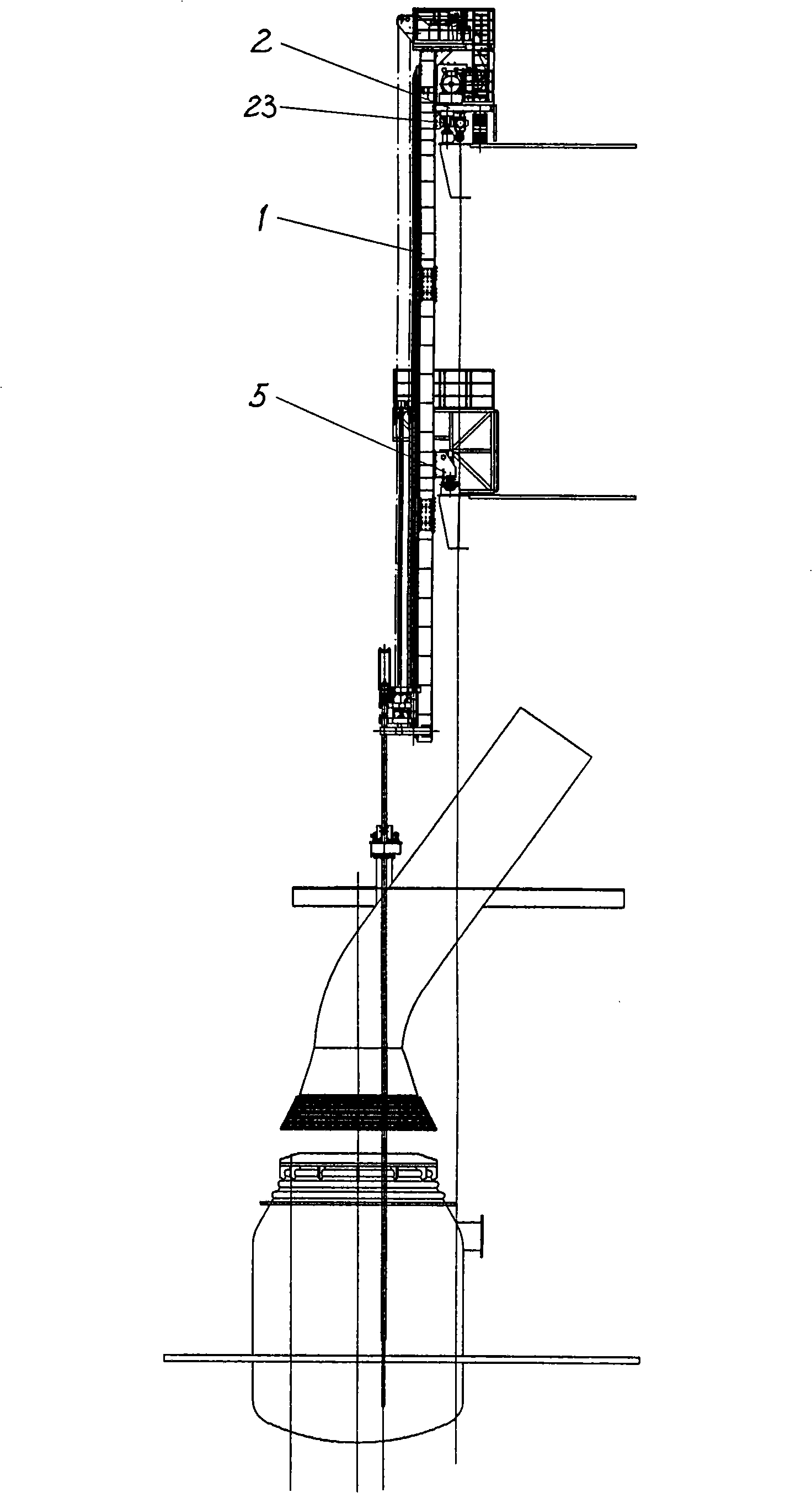

Cross sliding type sublance system

InactiveCN101314801APractical designEasy to manufactureManufacturing convertersWork cycleEngineering

The invention relates to a cross sliding type sublance system, which comprises a sublance system and a frame. The frame comprises a lifting frame and a cross sliding frame; the cross sliding frame comprises a cross sliding trolley frame body, a running wheel group and an upper side guide wheel device which are arranged on the bottom of the cross sliding trolley frame body, an upper orbit which supports the running wheel group and the upper side guide wheel device, and a lower orbit and a lower side guide wheel device, wherein, the upper orbit is arranged on a high level platform which is perpendicular to the lifting frame, and the lower orbit is arranged on a low level platform which is perpendicular to the lifting frame; the lower side guide wheel device is arranged on the lifting frame through a bracket. The cross sliding type sublance system has the advantages that the design is practical, the manufacture is easy, the installation is convenient, the running is stable and reliable, the working cycle is short, etc. The cross sliding type sublance system is especially suitable for the reconstruction project for adding the sublance system in old steelworks.

Owner:BAOSTEEL ENG & TECH GRP

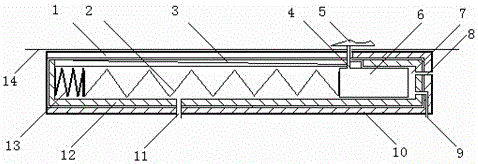

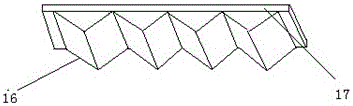

Rotary cylinder type fuel gas ejector

InactiveCN105730708ASimple structureExtended service lifeLaunching/towing gearCombustion chamberPiston ring

The invention provides a rotary cylinder type gas catapult, which is characterized in that: a tubular inner cylinder with an oblique opening is placed in a fully open tubular outer cylinder, and a tractor is installed on the upper part of the piston. The tractor moves the cylinder with oblique opening to rotate less than 350°, and closes the opening of the tubular outer cylinder. The advantages of the present invention are: simple structure, no preparatory work for use, long service life, less space occupation, and can also be used For steam ejection, the present invention includes: tubular outer cylinder opening part (1), return spring (2), tubular inner cylinder chute (3), tractor (4), aircraft (5), piston (6) , combustion chamber (7), inlet (8), rear exhaust port (9), tubular outer cylinder (10), front exhaust port (11), tubular inner cylinder (12), buffer spring (13), Flight deck (14), rectangular groove (15), wave type leaf spring (16), rectangular aluminum alloy sealing strip (17), roller (18), oblique opening plug of tubular inner cylinder (19), piston ring (20).

Owner:银世德

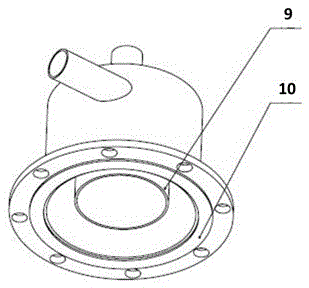

Corrosion-resistant spray nozzle of vacuum pump

The invention relates to the technical field of vacuum pumps, and discloses a corrosion-resistant spray nozzle of a vacuum pump. The corrosion-resistant spray nozzle comprises the following components in percentage by weight: 13.2 to 14.1% of silicon, 1.3 to 1.5% of titanium, 1.1 to 1.3% of niobium, 0.7 to 0.9% of rhodium, 0.6 to 0.8% of chromium, 0.4 to 0.5% of antimony, 0.32 to 0.37% of yttrium, 0.24 to 0.28% of scandium, 0.16 to 0.18% of rhenium, 0.11 to 0.13% of cobalt, 0.05 to 0.07% of ruthenium, and the balance of aluminum. The corrosion-resistant spray nozzle has the advantages that the preparation is simple, the working efficiency is increased by 17.3%, and the economic income is increased by 13.6%; the rich raw materials are provided, the acid and alkaline corrosion-resistant property and the high temperature-resistant property are realized after reinforcing and passivating treatment, the surface is smooth, the color and luster is uniform, the sealing property is good, the service life of the vacuum pump is prolonged by 18.2%, and the use value of the vacuum pump is obviously increased; by adding chitosan and peanut shell extract into a passivating liquid, the antibacterial and anti-oxidizing properties of the spray nozzle are improved.

Owner:ANHUI NANFANG CHEM PUMP IND

Collimating tool for uneven settlement of self-supporting iron tower

The invention discloses a collimating tool for the uneven settlement of a self-supporting iron tower, which solves the problems that a current tool is longer in work cycle, requires more operating personnel, and is higher in construction cost. The collimating tool is characterized by comprising an adjustable operation base, two lifting jacks, two zigzag support connecting tools and four thread supporting rods, wherein the adjustable operation base comprises an upper angle iron, an adjusting bolt, adjusting holes and a lower angle iron; each zigzag support connecting tool comprises a lifting baffle, reinforcement triangular irons, a junction plate, ear plates, thread supporting rod holes and a support plate. The collimating tool is simpler in structure, lighter, and easy to carry, is free of limitation of terrain where the pole and tower is, is shorter in work cycle, requires less operating personnel, is lower in construction cost, can achieve due collimating effect, reduces security risk and labor intensity, and improves the working performance.

Owner:STATE GRID CORP OF CHINA +1

Tin ingot brand character code mechanical automatic printer

The invention provides a tin ingot brand character code mechanical automatic printer. The tin ingot brand character code mechanical automatic printer comprises a tin ingot conveyor, a tin ingot pusher, a tin ingot printer, a tin ingot stacker and a guide rail anvil block. In a tin ingot mechanical and automatic production line under programming control of a PLC (programmable logic controller), the guide rail anvil block supports, blocks and clamps a tin ingot, two groups of rod hammers with character clips and character codes are arranged above the tin ingot, and simultaneously generate independent free falling motion impact, a lifting air cylinder is used, locking and unlocking pins are arranged on slide blocks of the lifting air cylinder, and lift the rod hammers through plug pins, and the rod hammers fall off by unlocking the plug pins. The tin ingot brand character code mechanical automatic printer has the advantages of being flexible in printing direction, sufficient in printing strength, distinct and beautiful in printing writing and pattern, quick in action, short in work period, timely in tin ingot processing, simple in structure, easy to manufacture, convenient to operate, high in running reliability, and low in running maintenance cost, and is a perfect device for achieving brand character code printing for products in the tin ingot mechanical and automatic production line.

Owner:YUNNAN TIN

Method for recycling denitration catalyst

ActiveCN103949290ADoes not affect the denitrification processShort duty cycleCatalyst regeneration/reactivationSocial benefitsEconomic benefits

The invention relates to a method for recycling a denitration catalyst. The method sequentially comprises the following steps according to production procedures: (1) blowing a waste catalyst by using steam; (2) soaking the catalyst by using an acidic solution or an alkaline solution; (3) cleaning the catalyst by using hot water; (4) coating the catalyst by using a mixed solution which contains vanadic oxide (V2O5), tungsten oxide (WO3) and titanium dioxide; and (5) calcining. According to the method, the denitration efficiency of the catalyst can be restored to 70%-90% of original denitration efficiency after the catalyst is recycled. The method disclosed by the invention has the advantages of short working period, easiness and convenience in operation, low cost and great economic benefit and social benefit.

Owner:耘太环保科技(山东)股份有限公司

Solid acid blockage remover and method for removing stratum blockage by using same

InactiveCN111621276ASolve the needs of long-distance transportationReduce riskCleaning apparatusDrilling compositionSolid acidEnvironmental engineering

The invention discloses a solid acid blockage remover and a method for removing stratum blockage by using the solid acid blockage remover. The solid acid blocking remover comprises a prepad fluid anda main treatment fluid, wherein the prepad fluid comprises the following components in percentage by weight: 8-16% of solid acid, 0.5-1.5% of a corrosion inhibitor, 0.5-1.5% of a clay stabilizer, 0.5-1.5% of an iron ion stabilizer, 0.5-1.5% of a demulsification cleanup additive and the balance of water; wherein the main treatment liquid is prepared from 5%-10% of solid acid, 4%-8% of ammonium fluoride, 0.5%-1.5% of a corrosion inhibitor, 0.5%-1.5% of a clay stabilizer, 0.5%-1.5% of an iron ion stabilizer, 0.5%-1.5% of a demulsification cleanup additive and the balance of water. The solid acidserves as main acid, most of other treating agents are solid particles, and the defects that special equipment is needed for liquid acid transportation, and long-distance transportation is high in safety risk are overcome.

Owner:PETROCHINA CO LTD

Device and method for rapidly separating sea buckthorn fruit seeds

The invention discloses a device and a method for rapidly separating sea buckthorn fruit seeds so as to solve problems existing in a traditional device, such as low separating efficiency and environment pollution. The device for rapidly separating sea buckthorn fruit seeds comprises an upper cylinder machine body, a lower cone machine body and a machine body bracket, wherein a lower overflow opening is formed in the bottom of the lower cone machine body, and a ball valve is arranged on the lower overflow opening. The method for separating sea buckthorn fruit seeds comprises the following steps: filtering fresh sea buckthorn pomace left after fruit juice is squeezed by a rotary screen, and removing fruit stems; fetching pomace, and adding cellulose to carry out separation early-stage enzymolysis; and after enzymolysis is over, uniformly mixing materials and water according to a mass-to-size ratio of 1:40 to 1:30, controlling the temperature of materials between 25DEG C and 40DEG C, regulating the opening degree of the ball valve of the lower overflow opening between 30 degrees and 60 degrees, and utilizing hydraulic power to separate sea buckthorn fruit seeds. The device can ensure that sea buckthorn pomace wastes are smoothly discharged in the test process; and the ball valve is mounted on the lower overflow opening, through regulating the opening angle of the ball valve, pressure in the cavity of a cyclone separator can be controlled, and the smooth separation of seeds is realized.

Owner:GANSU AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com