Cross sliding type sublance system

A lateral movement and lateral movement technology, applied in the direction of manufacturing converters, etc., can solve the problem that the rotating frame type sub-gun cannot be added, and achieve the effect of practical design, stable and reliable operation, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

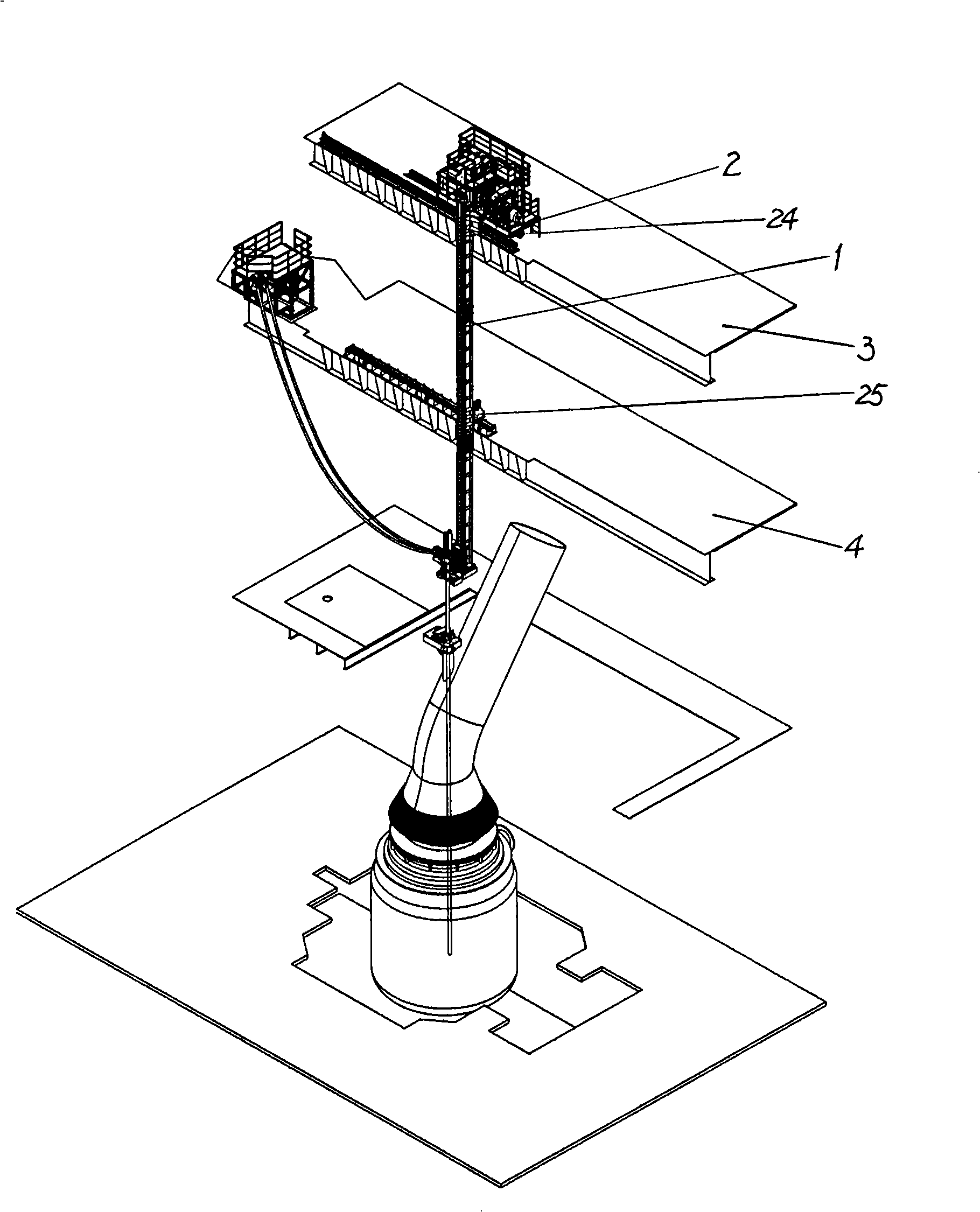

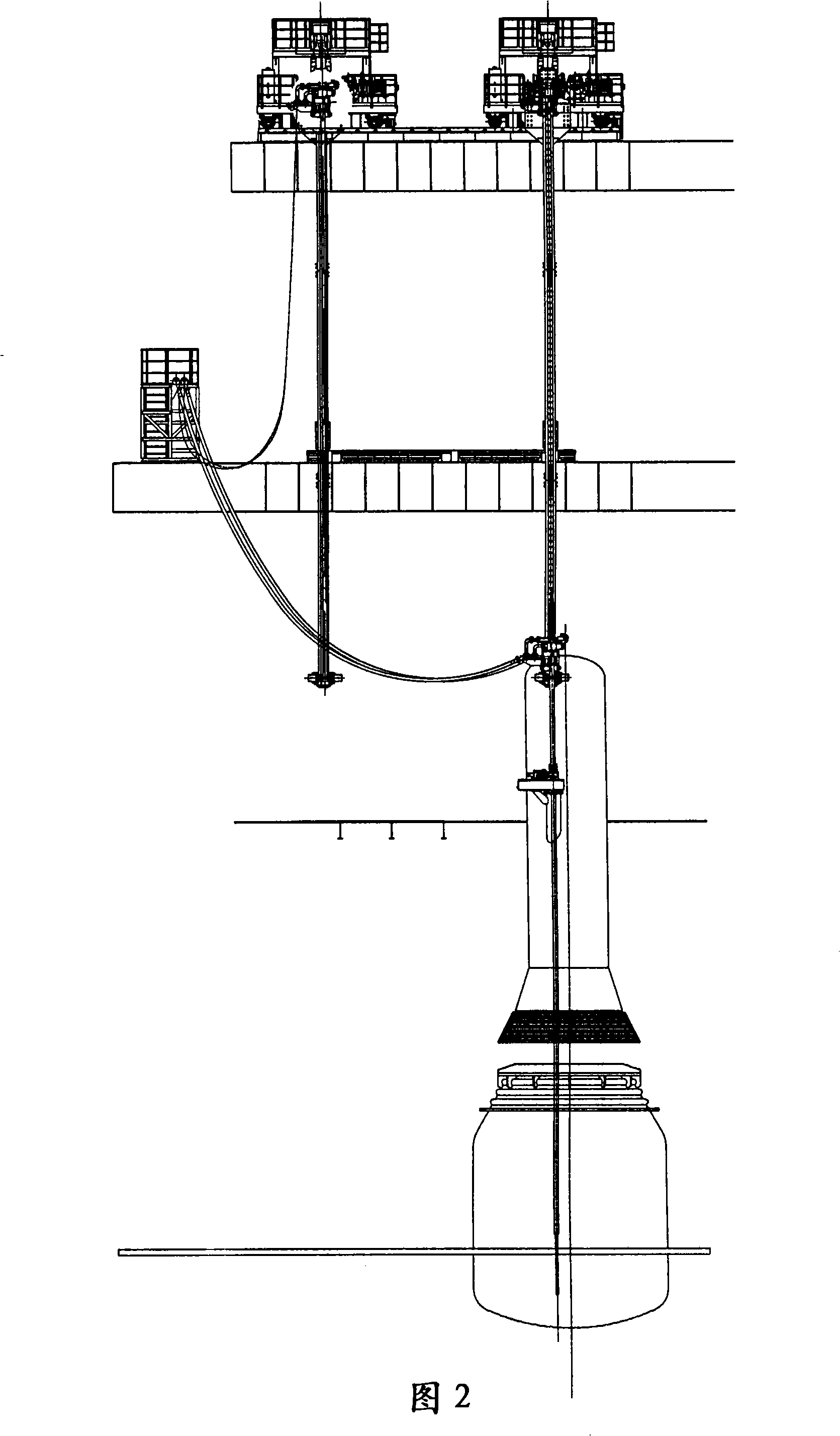

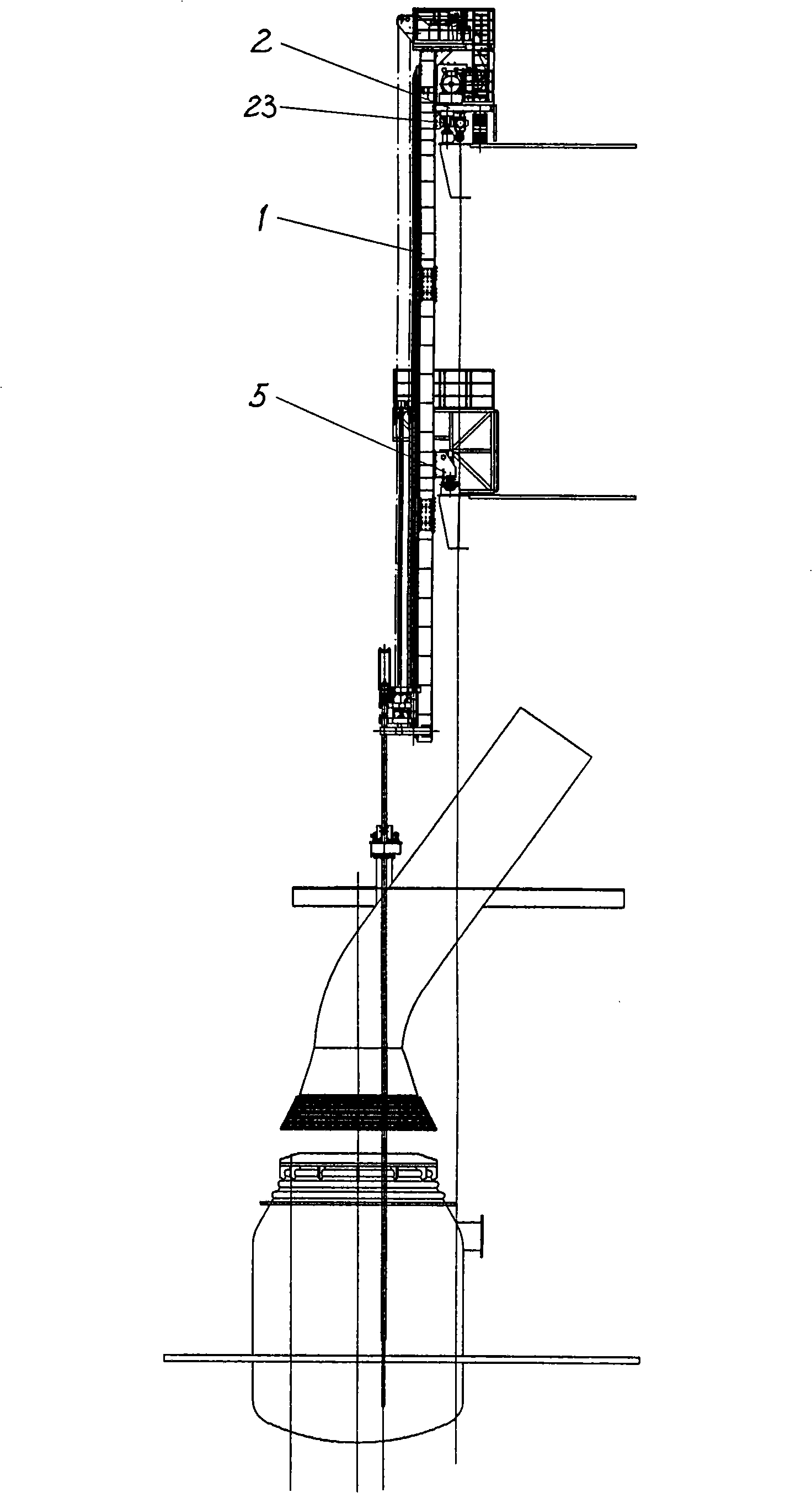

[0015] see Figure 1 to Figure 7 , a kind of traversing sub-gun system of the present invention comprises sub-gun system and frame, and frame is made up of lifting frame 1 and traversing frame 2.

[0016] The traversing frame 2 includes a traversing trolley frame body 21 , a traveling wheel set 22 , an upper side guide wheel device 23 , an upper track 24 , a lower track 25 and a lower side guide wheel device 26 . The traveling wheel group 22 is placed on the bottom of the traversing trolley frame body 21, and the upper track 24 is placed on the high-rise platform 3 perpendicular to the lifting frame 1, and the upper rail 24 supports the traveling wheel group 22 and the upper side guide wheel device 23.

[0017] Such as Figure 5 As shown in , the upper side guide wheel assembly 23 is laterally supported on the side of the upper rail 24 . The upper side guide wheel device 23 is provided with two guide wheels. The upper side guide wheel device 23 is provided with two guide wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com