Rotary cylinder type fuel gas ejector

A technology of rotating cylinders and catapults, applied in the direction of launch/drag transmission devices, etc., can solve the problems of large space occupation, impracticality, large power consumption, etc., and achieve the effects of long service life, simple structure, and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

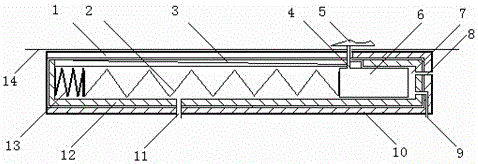

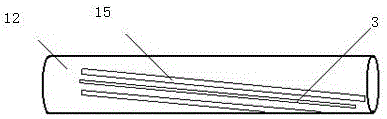

[0027] According to attached figure 1 As shown, first open an opening with a width of about 30 mm from one end of the tubular outer cylinder (10) to the other end. When the piston is about to reach the top dead center, the corresponding tubular outer cylinder (10) at the position of the rear end of the piston On one side, open a front exhaust port (11), then fix the tubular outer cylinder (10) below the flight deck (14), the tubular outer cylinder opening (1) is aligned with the traction groove of the flight deck (14), The front exhaust port (11) is connected to the outside of the ship with a pipeline. On the tubular inner cylinder (12), open one with the tubular outer cylinder opening (1), the oblique opening (3) of the tubular inner cylinder equal in length and width. On both sides of the inclined opening (3) of the tubular inner cylinder, a rectangular groove (15) identical with the length and width of the inclined opening is respectively set, (referring to figure 2 ). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com