Monitoring and processing system for operating environment of electrical equipment

A technology for environmental monitoring and processing systems, applied in signal transmission systems, measuring devices, liquid level indicators through pressure measurement, etc., can solve problems such as reduced cable life, heavy workload, condensation, etc., to reduce accidents , reduce serious waste, and solve the effect of long-term water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

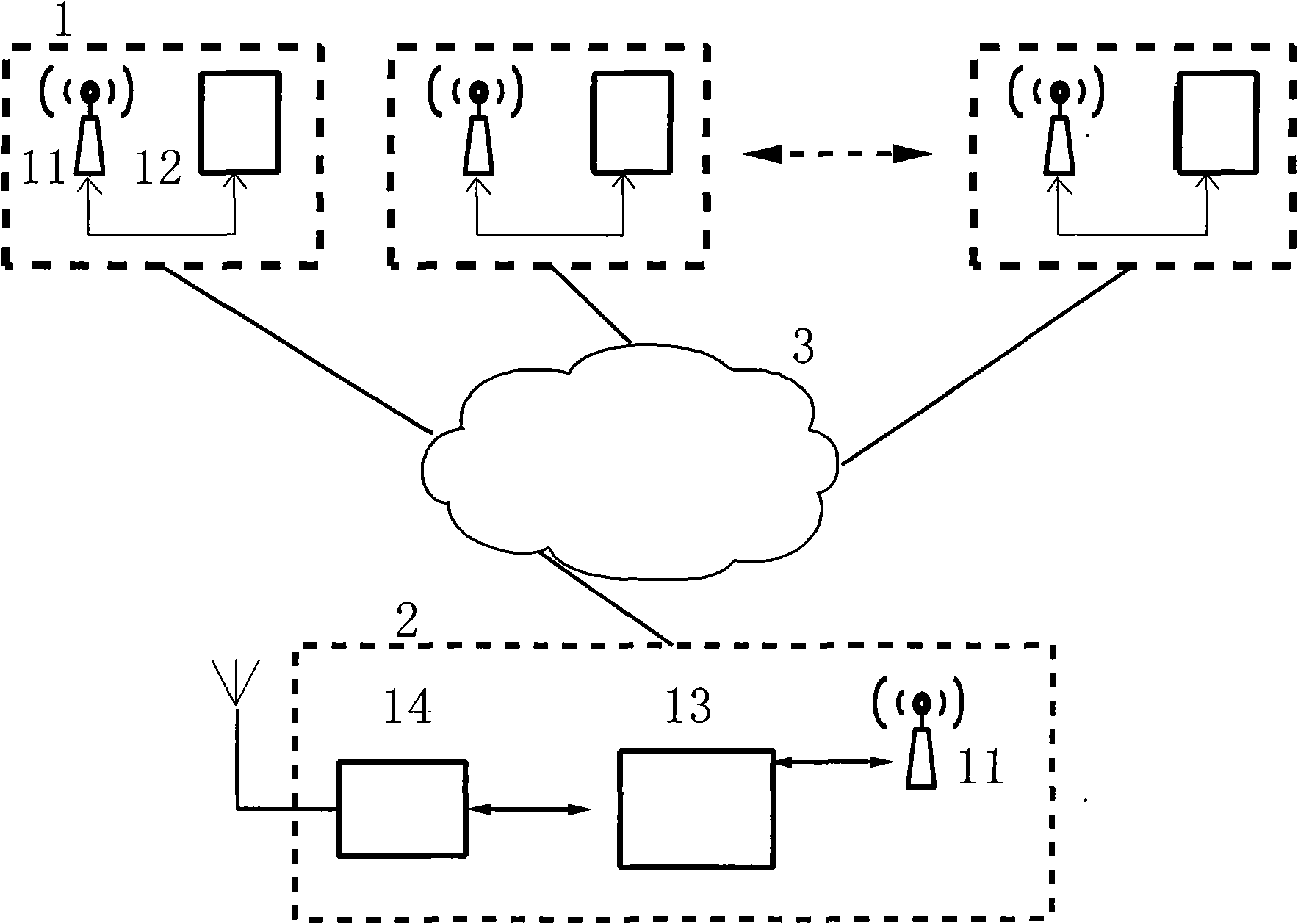

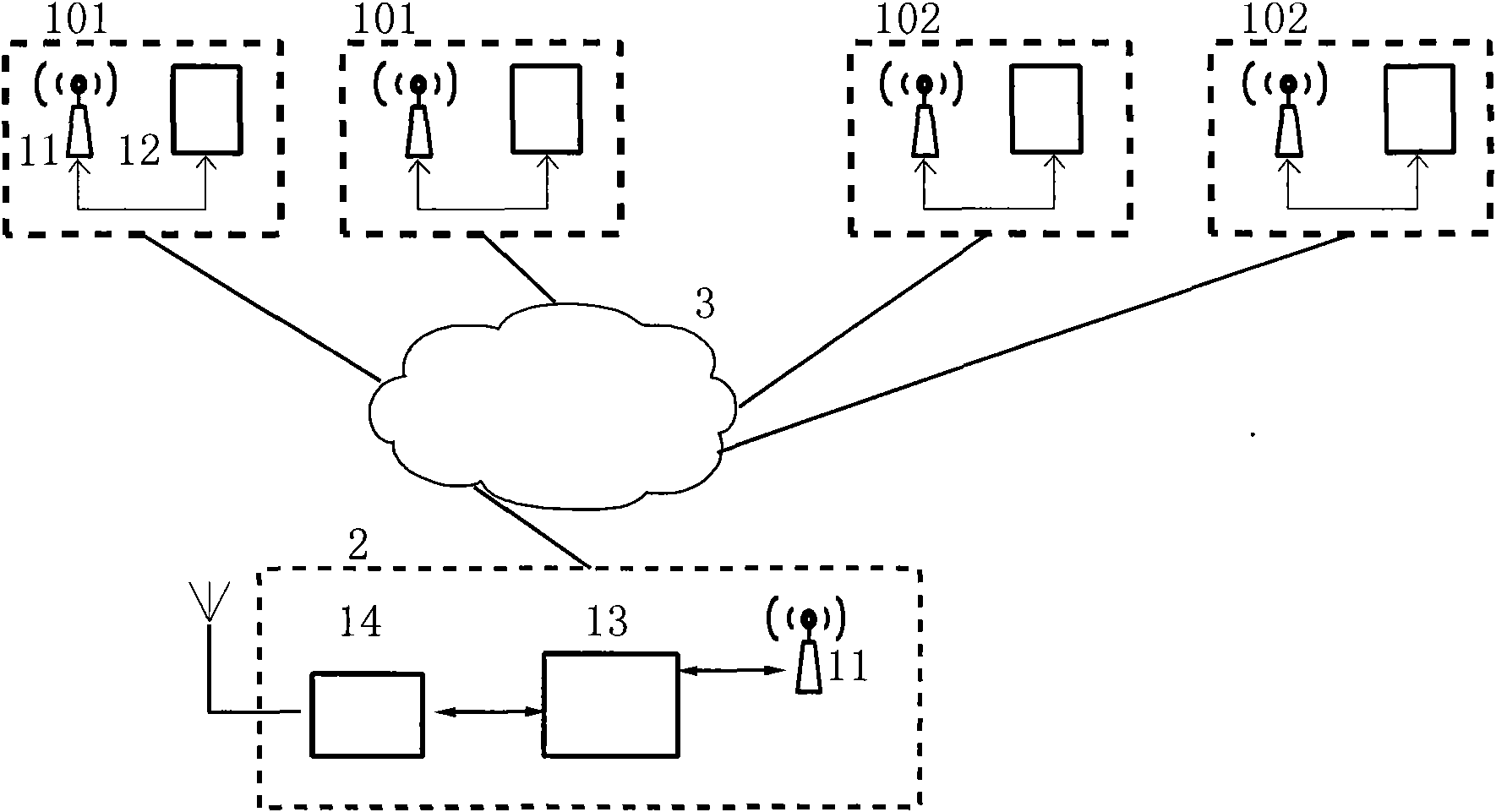

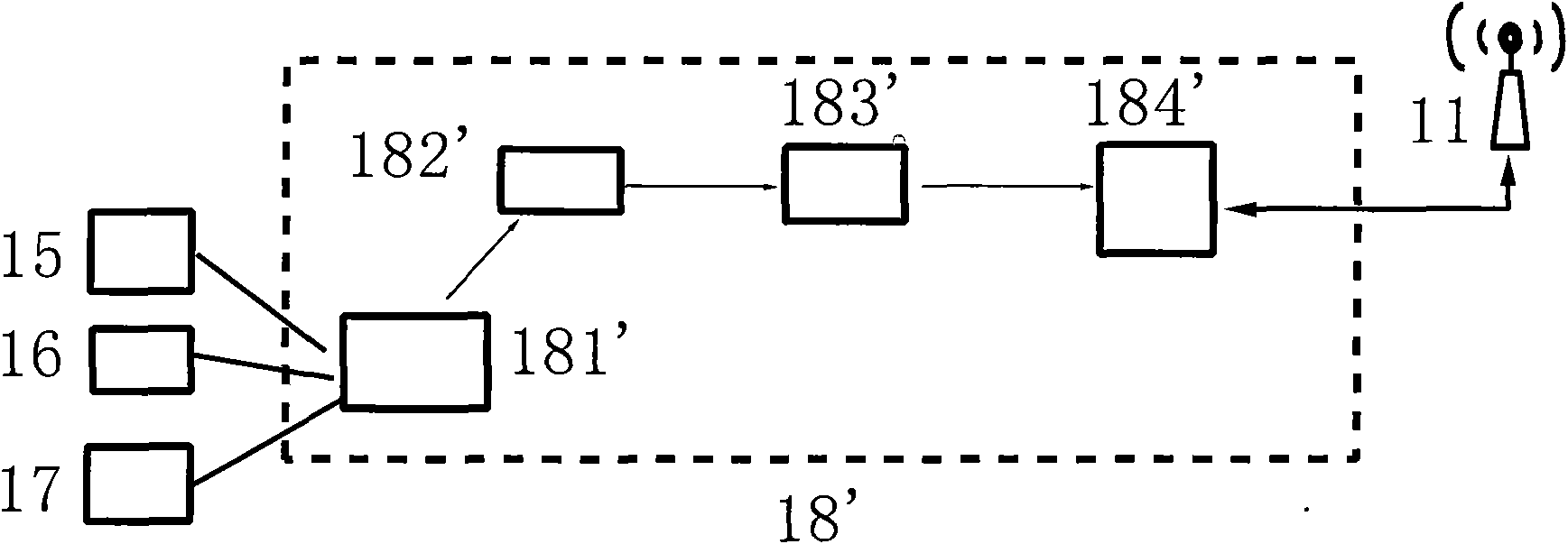

[0016] Embodiment: a kind of electrical equipment operating environment monitoring processing system (see Figure 1-Figure 4 ), which includes at least one detection unit 1 for collecting detection signals and a main control unit 2 for receiving information of a plurality of detection units, the detection unit 1 is composed of a detection control module 12 and a short-distance wireless communication module 11 connected, the main Control unit 2 is connected and constituted by main control module 13, short-distance wireless communication module 11 and GSM communication module 14, and main control module 13 is connected with GSM module communication module 14 and short-distance wireless communication module 11 respectively; The units 2 are connected through a short-distance wireless communication network 3 . The detection unit 1 can be freely configured as required, including a freely configurable number of water level detection units 101 and a freely configurable number of tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com