Magnetic levitation compound molecular pump

A composite molecular pump and magnetic levitation technology, which is applied in the direction of pumps, pump control, pump components, etc., can solve the problems that the installation angle can only be vertical or horizontal, the molecular pump is difficult to achieve high speed, and the average trouble-free working cycle is short. Achieve the effects of simplifying the electrical control design, short trouble-free working period, and avoiding large rotor swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

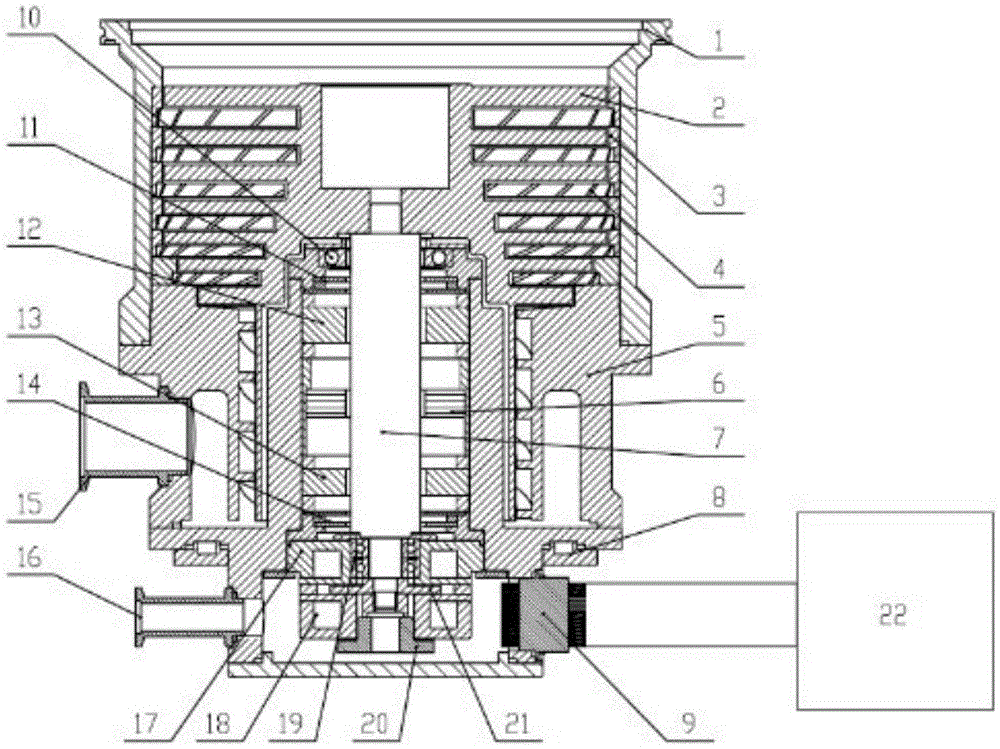

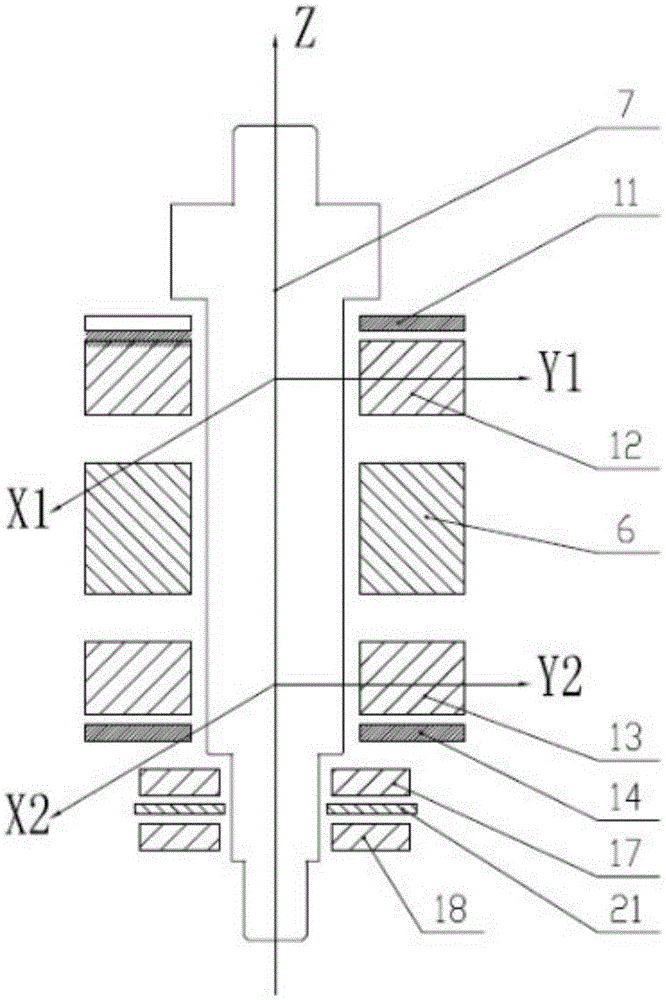

[0048] Embodiment 1: as figure 1 As shown, this embodiment consists of a pump casing 1, an impeller 2, a spacer ring 3, a static plate 4, a traction stage stator 5, a permanent magnet high-speed motor 6, a circulating water spacer ring 8, an air outlet flange 15, and a protective gas flange 16 , Upper protective bearing 10, lower protective bearing 19, five-degree-of-freedom magnetic suspension bearing, upper radial sensor 11, lower radial sensor 14, axial sensor 20, thrust plate 21 and controller 22.

[0049] The axial sensor 20 is arranged under the thrust plate 21 , and the spacer ring 3 is arranged between the impeller 2 and the pump casing 1 . The circulating water spacer ring 8 is arranged on the edge of the stator of the permanent magnet high-speed motor 6 , the air outlet flange 15 is arranged on the traction stage stator 5 , and the protective gas flange 16 is arranged on the base of the traction stage stator 5 .

[0050] The controller 22 is connected with the magne...

Embodiment 2

[0061] This embodiment is similar to embodiment 1, and its difference is:

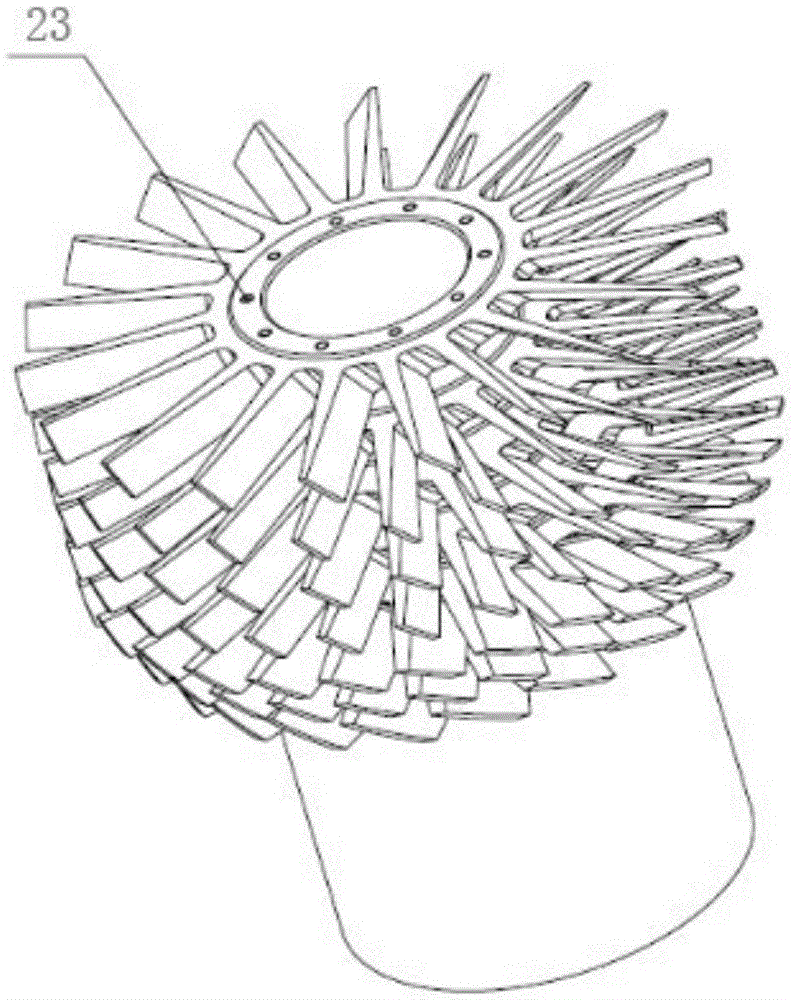

[0062] 1. The impeller 2 adopts an integral design, and high-strength alloy materials are selected to be formed by one-time milling by a multi-axis machining center; the blades of the impeller 2 adopt a variable-section design, and the upper end surface of the impeller 2 is provided with screw holes 23 uniformly distributed around the circumference for Regulates the unbalanced distribution of the mass of the rotor system.

[0063] 2, the control process of controller 22 is as follows:

[0064] S1. Automatically adjust the unbalanced vibration of the rotor system:

[0065] S11. When the electromagnetic main shaft 7 is in a static levitation state, extract and extract the same-frequency components of the control currents of the upper and lower radial magnetic bearings and the upper and lower shaft axial magnetic bearings respectively through the signal measurement circuit, and calculate the magnetic cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com