Manual capsule coffee maker

A technology for coffee machines and capsules, which is applied in the field of beverage making devices, can solve the problems of modeling design restrictions, increased volume of the whole machine, and can only be installed on one side of the body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail to the preferred embodiments of the present invention, which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. In order to illustrate the present invention with reference to the figures, the preferred embodiments are described below.

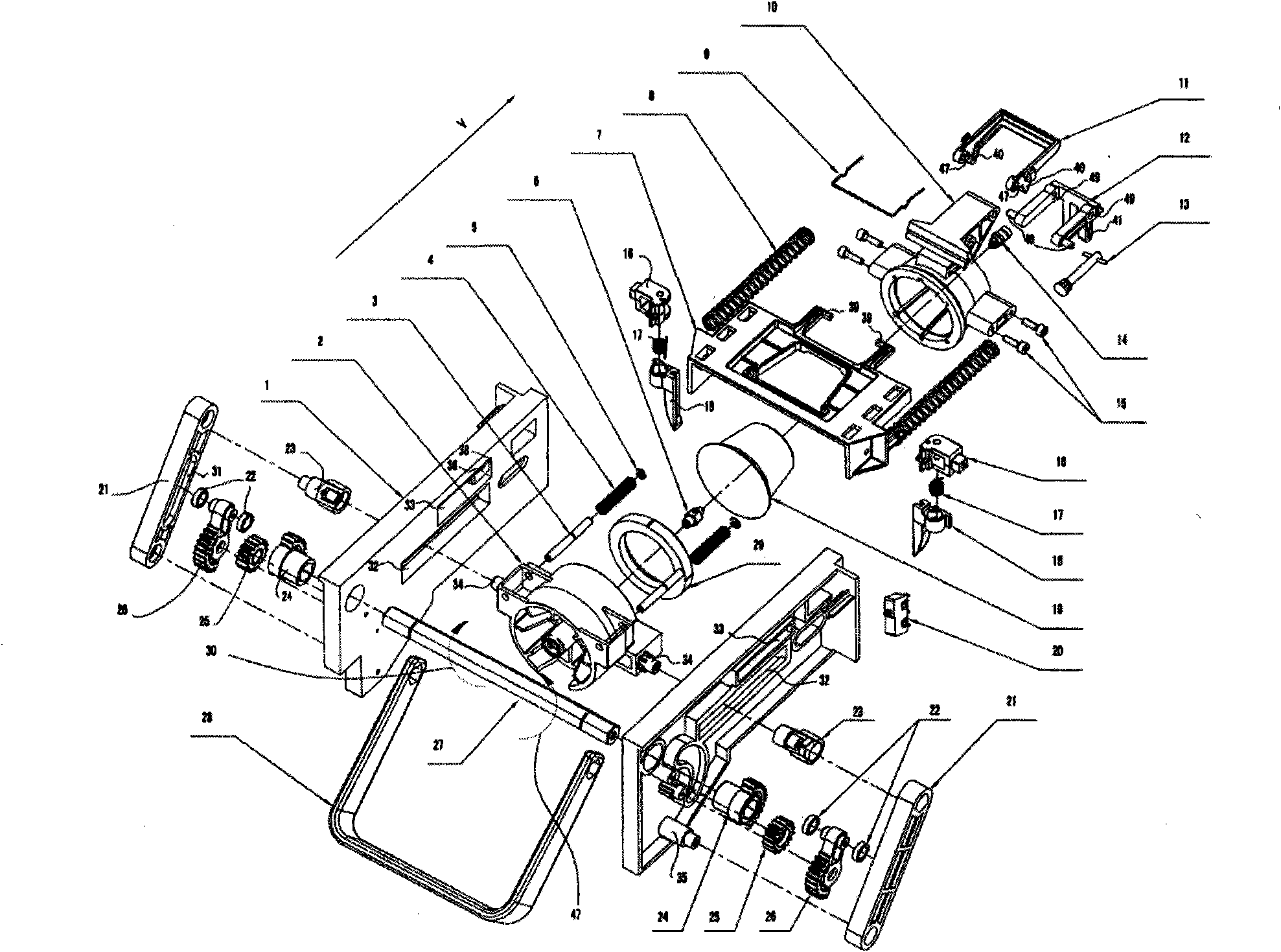

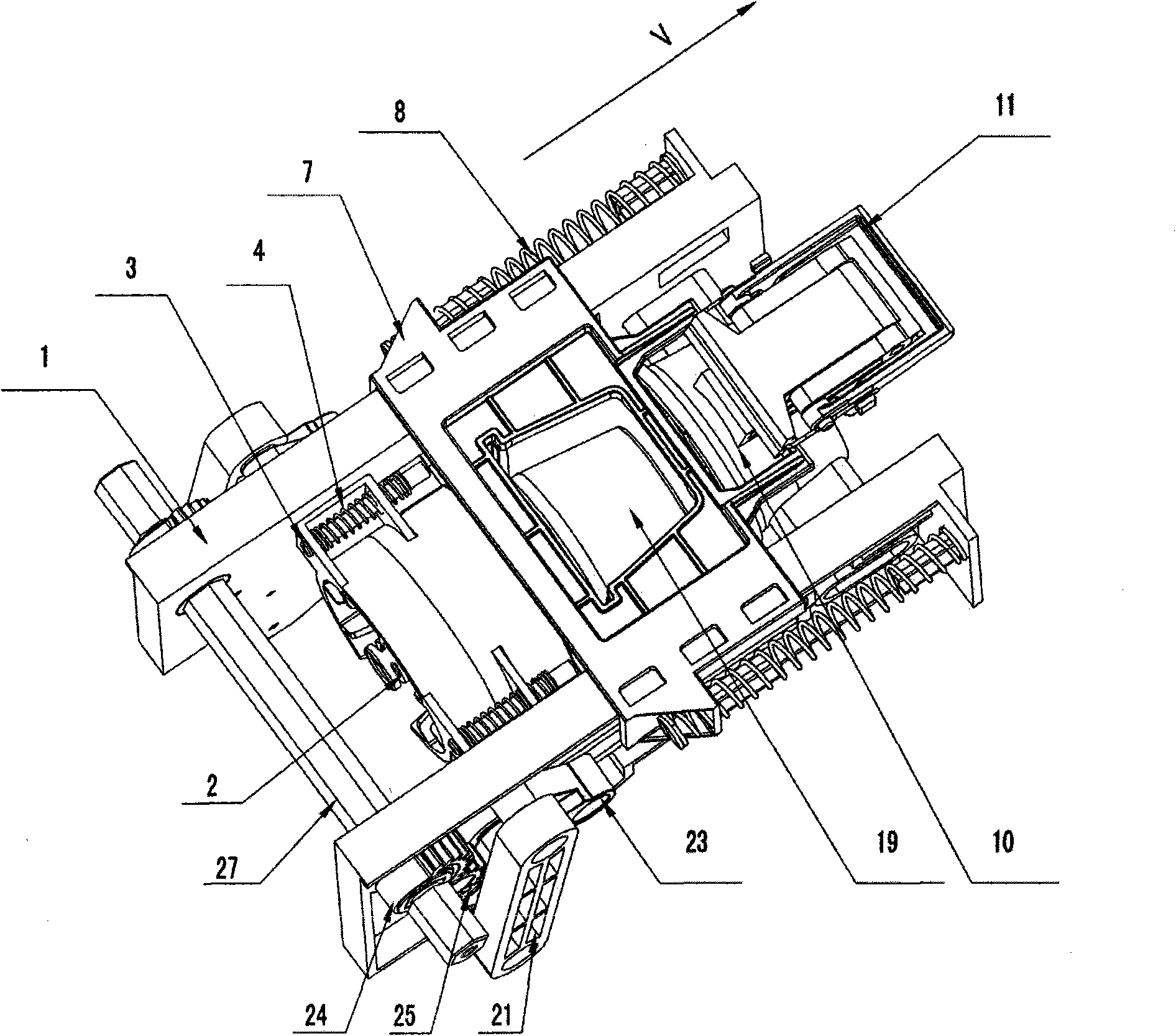

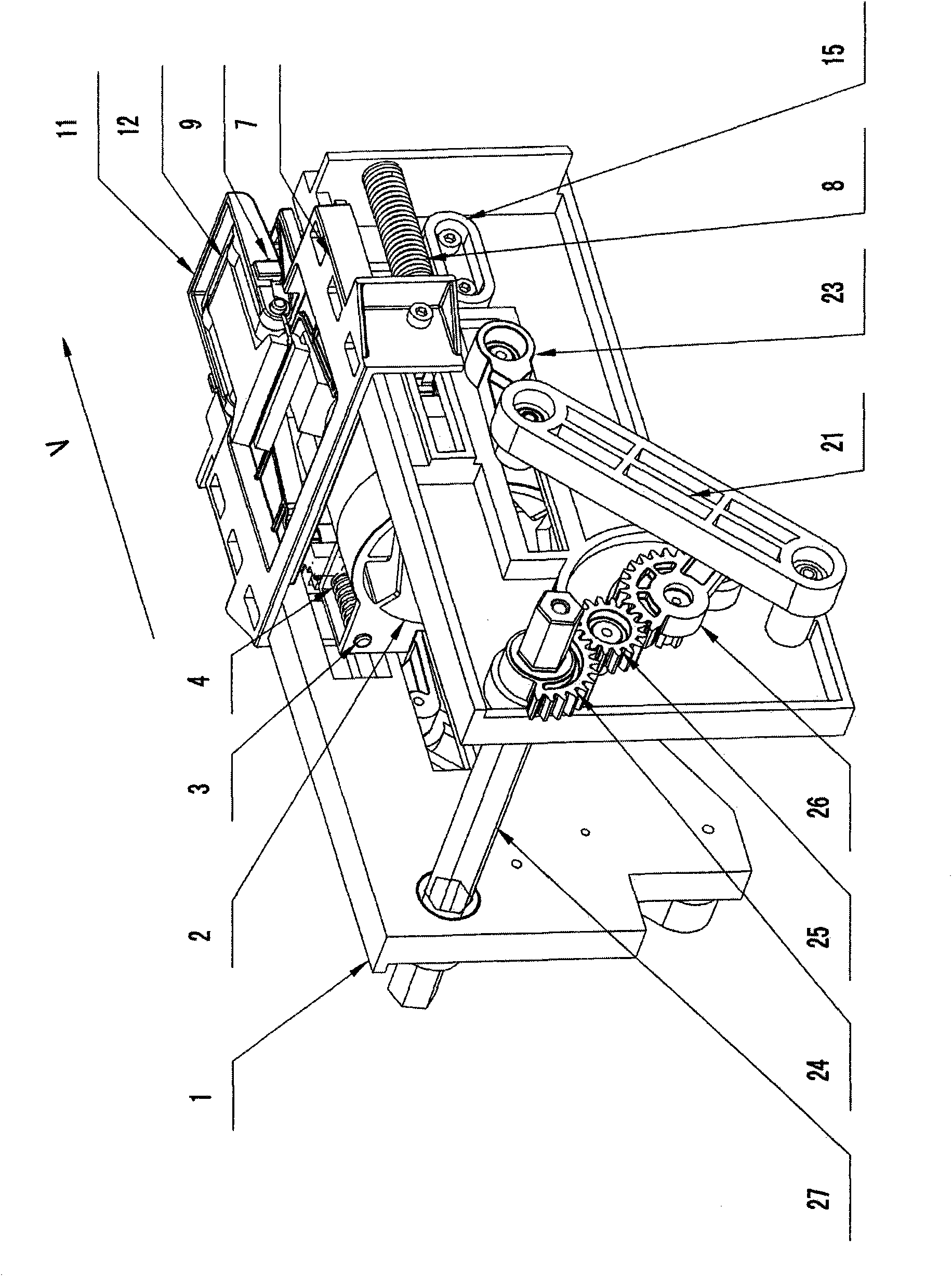

[0040] See attached Figures 1 to 7 , the manual capsule coffee machine of the present invention includes a brewing mechanism, which at least includes a brewing head 2, a front piercing needle 6, a coffee box 10, a sealing ring 29, a transmission mechanism 21-27, and a capsule feeding mechanism 3,4 , 5, 7. Capsule guiding mechanism 15-18, capsule automatic ejection mechanism 8-13, also includes a bracket 1, the bracket 1 is provided with gear structures 36, 38, as attached Figure 12 And attached Figure 13 As shown, the capsule guiding mechanisms 15-18 have at least the working position of clamping the coffee capsule and the working posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com