Multi-cutting type synthetic leather cutting device and cutting manufacturing process thereof

A technology of multiple cutting and cutting devices, which is applied in the cutting of textiles, papermaking, and textile materials, and can solve problems such as inconvenient use, hidden safety hazards, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

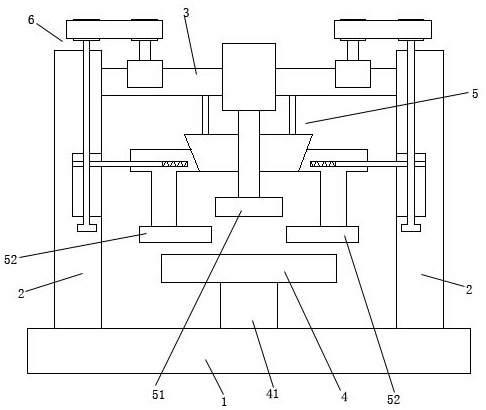

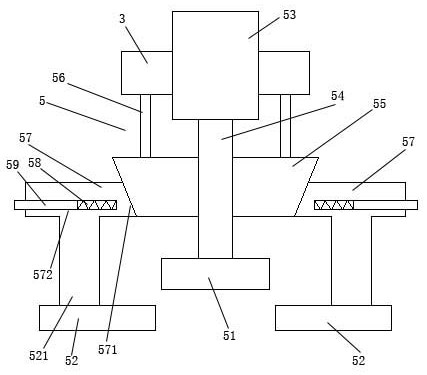

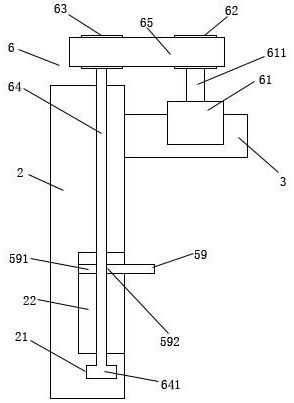

[0019] Such as Figures 1 to 3 As shown, a multi-cut synthetic leather cutting device includes a base 1, a side support plate 2, a top plate 3, a multiple cutting mechanism 5, and a working table 4; a side support plate is respectively installed on both sides of the upper end of the base 1 2. The top plate 3 is installed between the upper ends of the side support plates 2; the multiple cutting mechanism 5 includes a telescopic rod 54, a middle cutting knife 51, an annular socket block 55, a positioning rod 56, a side moving block 57, and a longitudinal floating Plate 58, side cutting knife 52, pressing elastic body 58; the telescopic rod 54 is telescopically installed under the middle of the top plate 3; the lower end of the telescopic rod 54 is equipped with the middle cutting knife 51; Connected to the outer sides of the middle of the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com