Opening and closing plate structure of range hood

A range hood, opening and closing plate technology, applied in the direction of removing oil fume, household stove/stove, heating method, etc., can solve the problems of unable to realize intelligent partition smoke control, unable to match the size of the lampblack below, unable to independently adjust the opening and closing position of the opening and closing plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

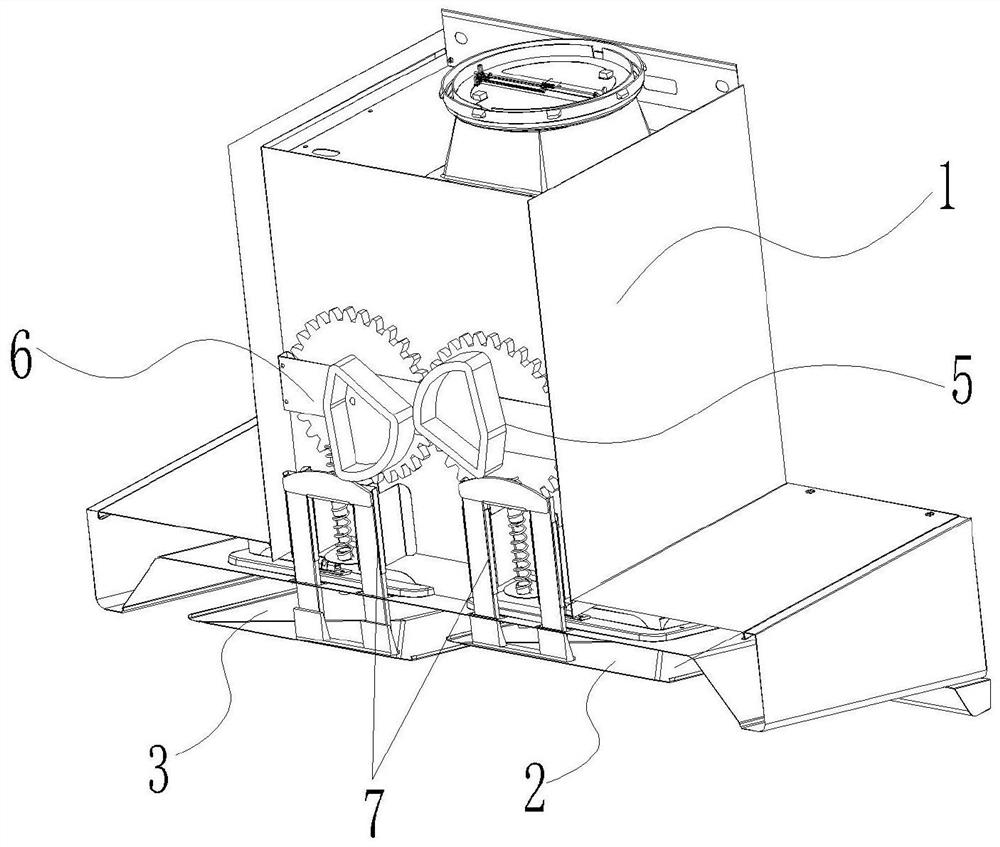

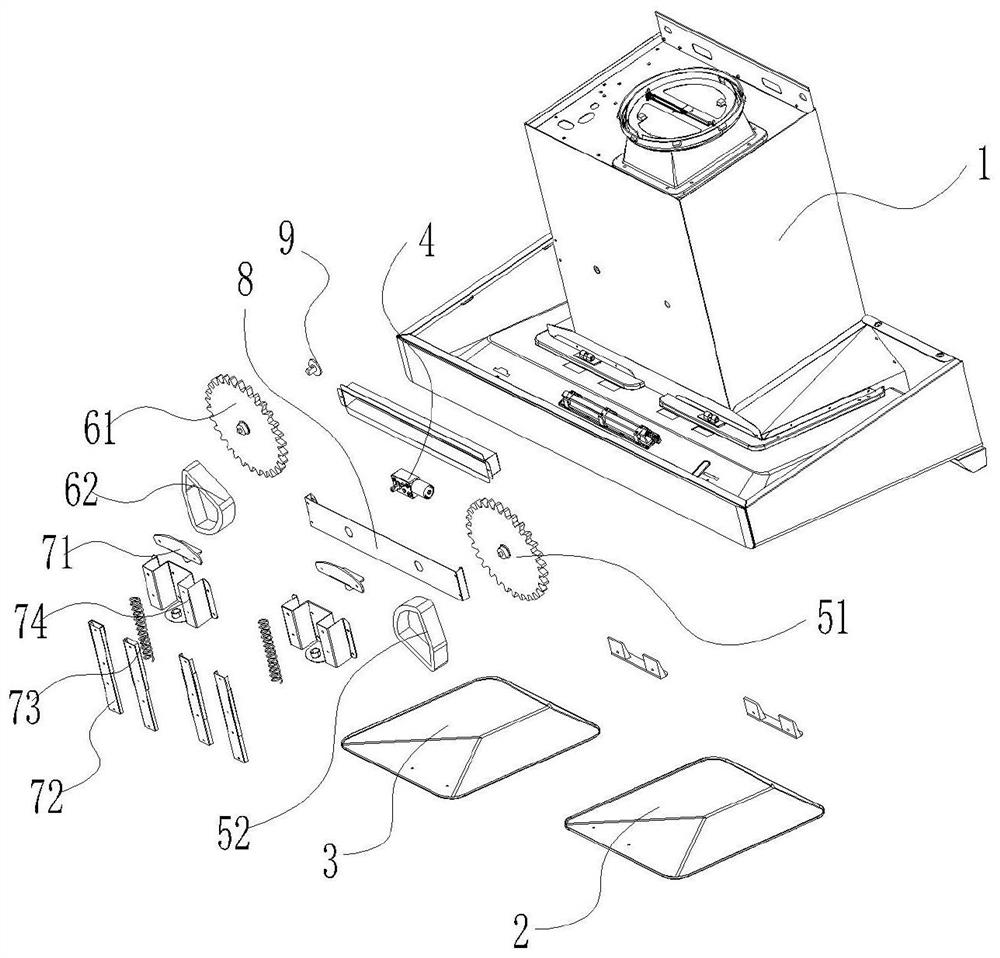

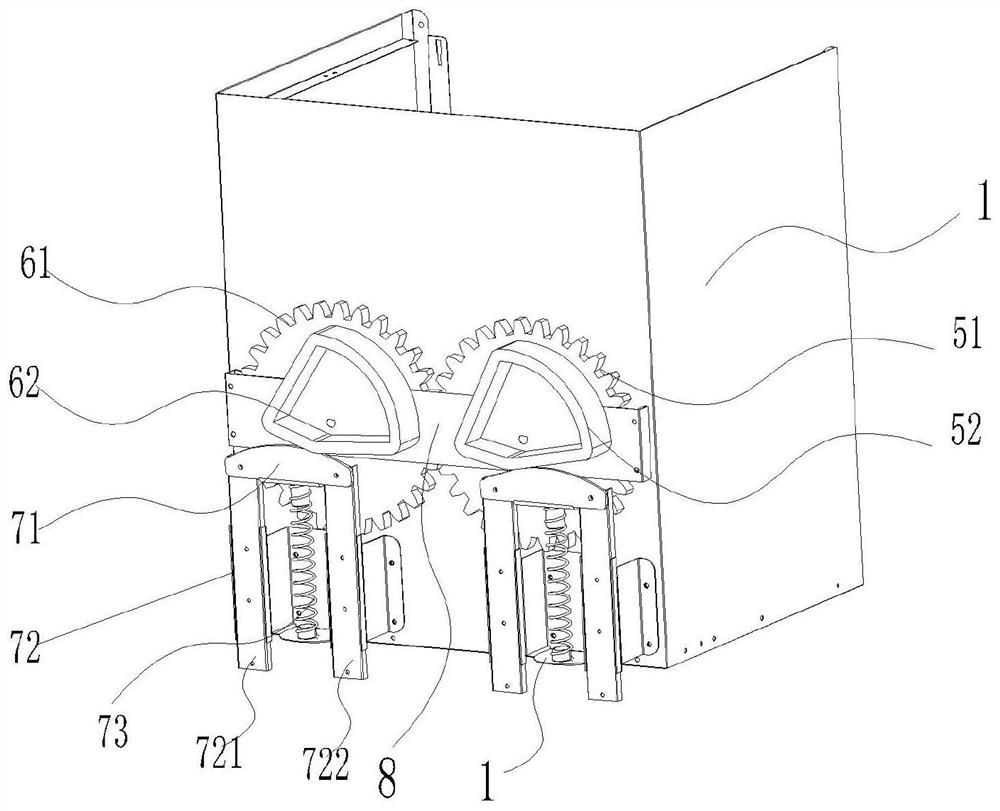

[0026] Such as Figures 1 to 6 As shown, this embodiment provides an opening and closing plate structure of a range hood, which includes a main body 1 of the range hood, on which a first air inlet and a second air inlet are opened, and also includes a first opening and closing plate 2, a second Two opening and closing plate 3, driving device 4, first transmission assembly 5, second transmission assembly 6, lifting assembly 7 and control device, wherein the first opening and closing plate 2 is installed on the main body 1 of the cigarette machine and is movably arranged at the first air inlet , the second opening and closing plate 3 is installed on the main body 1 of the cigarette machine and is movably arranged at the second air inlet, the driving device 4 is arranged on the main body 1 of the cigarette machine, and one end of the first transmission assembly 5 and / or the second transmission assembly 6 is respectively connected to the The output end of the driving device 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com