Double-column ink cartridge automatic ink filling equipment

An ink filling and ink cartridge technology, which is applied in the field of ink cartridge manufacturing equipment, can solve problems such as low ink filling efficiency, ink filling failure, ink filling head damage, etc., and achieve the effects of improving ink filling efficiency, increasing service life, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

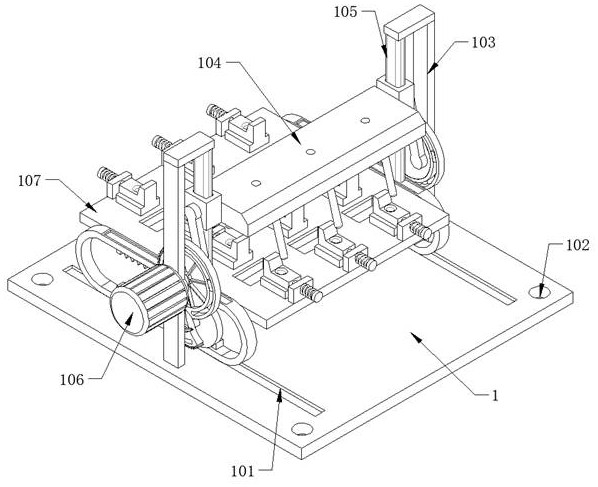

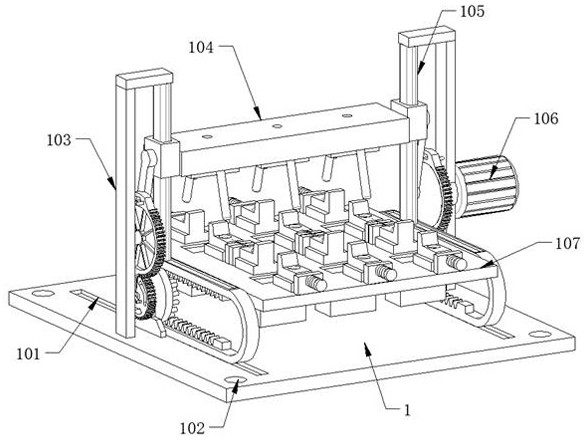

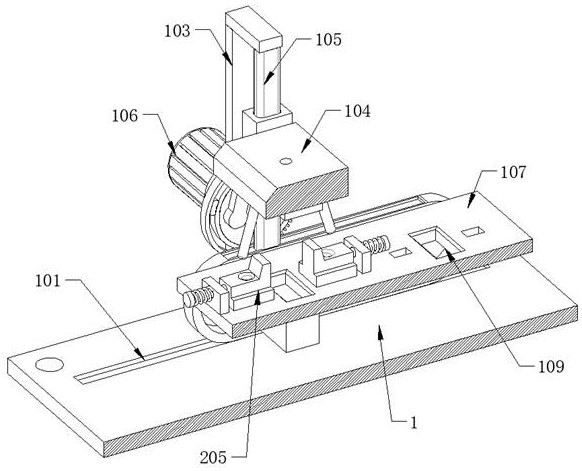

[0032] refer to Figure 1-8 , an automatic ink filling device for a double-column ink outlet type ink cartridge, comprising a base 1 and mounting holes 102 evenly opened on the top of the base 1, and further comprising:

[0033] The ink filling assembly is arranged on the top of the base 1. The ink filling assembly includes a column 103 and a sliding guide rail 105. The column 103 is installed on the top of the base 1. The sliding guide rail 105 is connected to the side wall of the column 103. The outer wall of the sliding guide rail 105 is slidably connected with a sliding block 108. The output end of the ink filling assembly is connected to the ink filling plate 104, and the bottom of the ink filling plate 104 is provided with an ink filling head 201 and a guide rod 202;

[0034] The moving assembly is arranged on the top of the base 1. The moving assembly is matched with the ink injection assembly. The output end of the moving assembly is connected to the mounting plate 107...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com