Method and system for controlling light erasing voltage of liquid crystal writing device

A technology for erasing voltage and writing devices, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of slow voltage change between the base layer and liquid crystal layer, long erasing time, and poor TFT photosensitivity, so as to improve writing Experience, improve writing efficiency, and avoid the effect of fading handwriting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

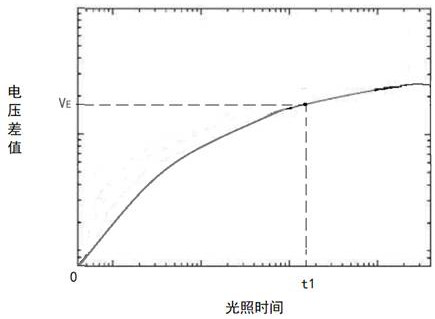

[0032] As described in the background technology, when light is used for partial erasing, the photoconductive current will be too small due to the small TFT light transmission port, too low doping concentration of the TFT channel, or too large storage capacitance, resulting in The charging voltage between the base layer and the liquid crystal layer is small, and it takes a long time to illuminate to make the voltage difference between the set erasing electrode and the conductive layer reach the erasing voltage of the liquid crystal, and the time required for partial erasing Longer, lower writing and erasing efficiency, poor user experience.

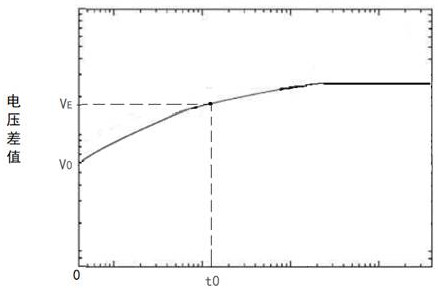

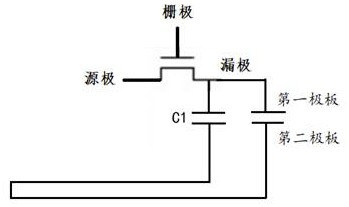

[0033] According to an embodiment of the present invention, a method for controlling an illumination erasing voltage of a liquid crystal writing device is disclosed. The liquid crystal writing device based on the method includes: a conductive layer, a bistable liquid crystal layer, and a base layer arranged sequentially from top to bottom....

Embodiment 2

[0057] According to an embodiment of the present invention, an embodiment of an illumination erasing voltage control system for a liquid crystal writing device is disclosed, which specifically includes:

[0058] A voltage control module, used to control the voltage difference between the base layer and the conductive layer within a set voltage value range below the erasing voltage of the liquid crystal;

[0059] The partial erasing module is used to control all or a set part of TFTs on the base layer to be in a critical state, and realize partial erasing by using light irradiation within a set intensity range.

[0060] It should be noted that the specific implementation manners of the above modules have been described in detail in Embodiment 1, and will not be described in detail here.

Embodiment 3

[0062] According to an embodiment of the present invention, a voltage drive controller is disclosed, and the controller loads and executes the method for controlling the illumination erasing voltage of a liquid crystal writing device described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com