Rail transit damping mechanism

A shock absorption mechanism and rail transit technology, applied in the field of rail transit shock absorption, can solve problems such as increased friction between trains and rails, shortened rail service life, and inability to achieve high-efficiency shock absorption, and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

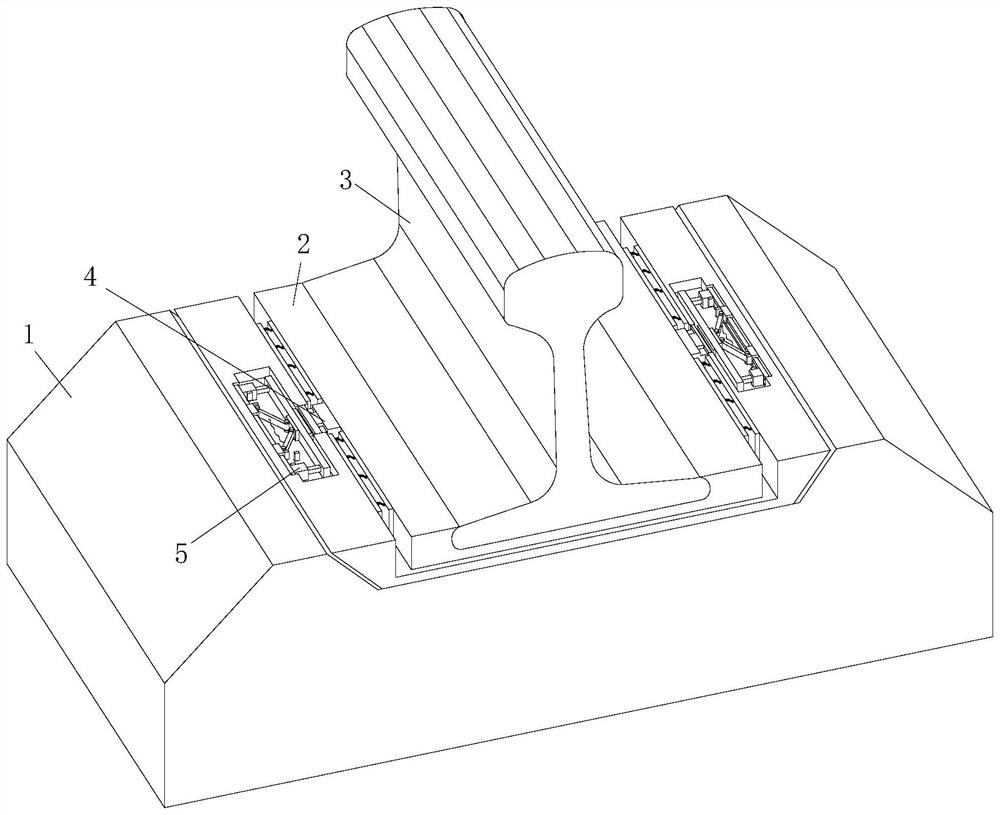

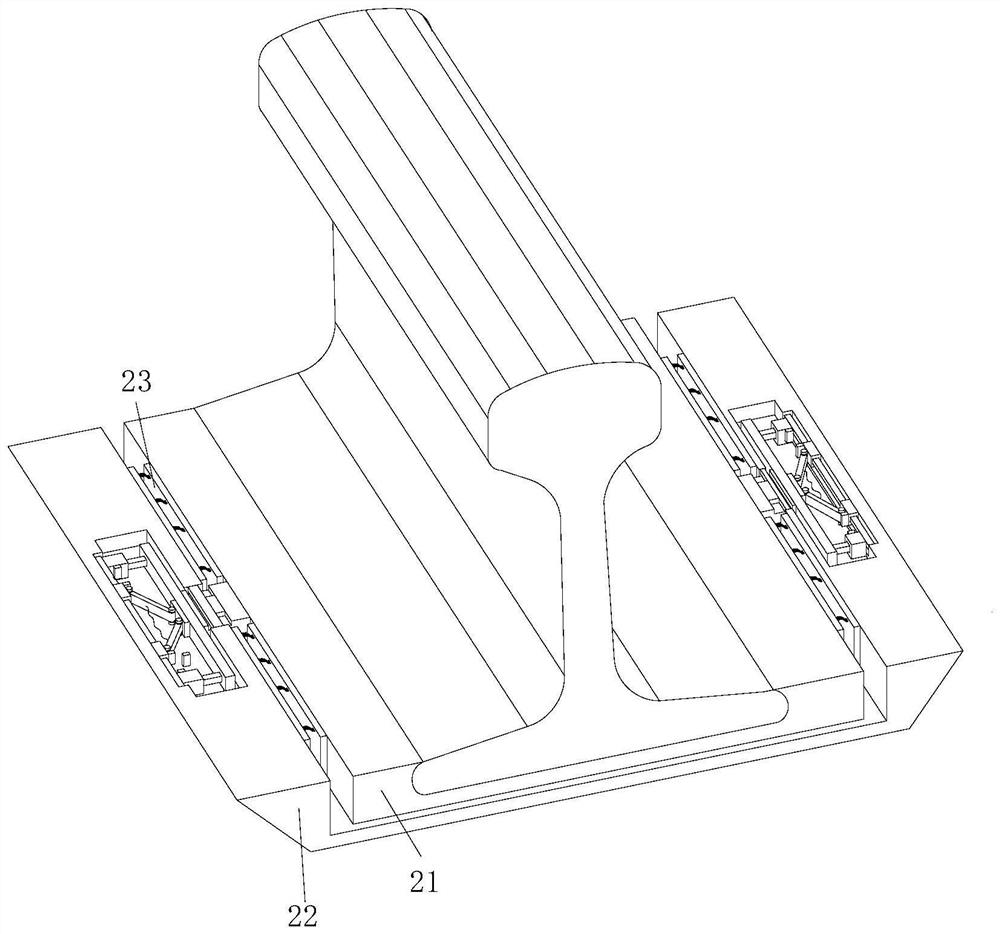

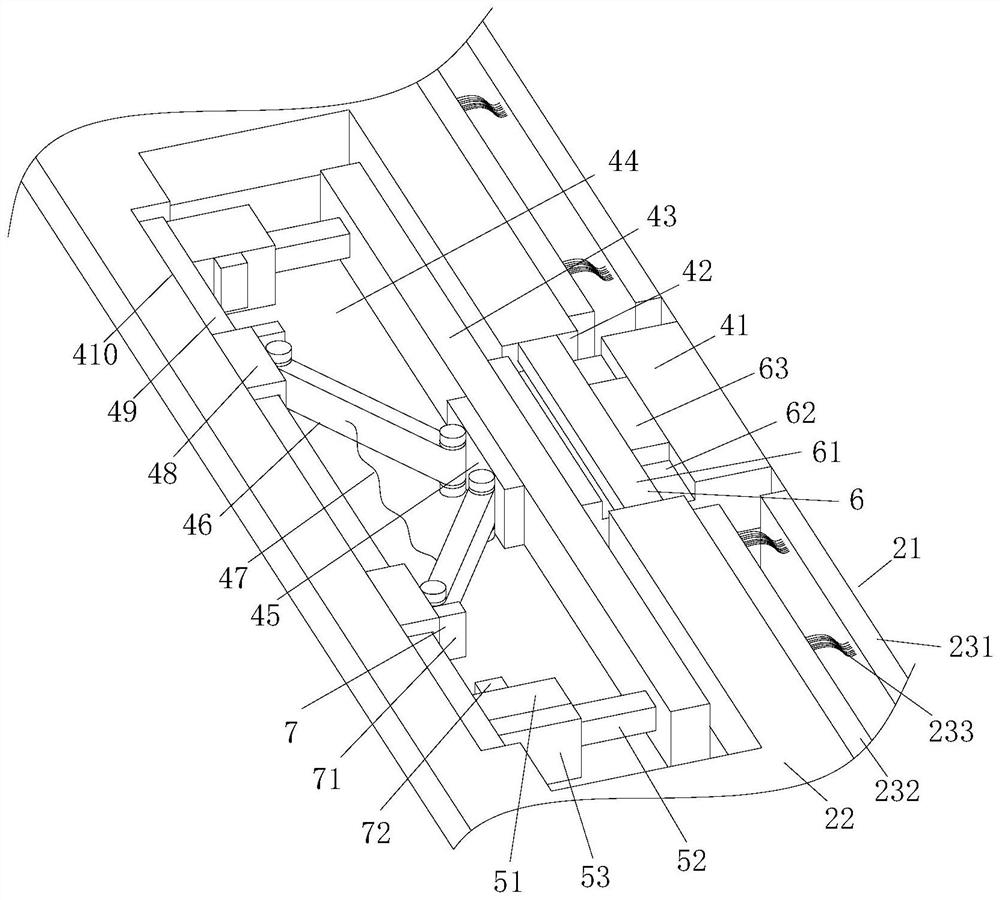

[0032] By the following Figure 1-5 And examples are further illustrated by the present invention:

[0033]A rail transit damping mechanism comprising a sleeper 1 and a track body 3, a track damper 2 is provided on a rail pillow 1, and the track body 3 is disposed on the track damper 2, and the track damper 2 includes a soft wear-resistant elastic plate 21. The soft body wear-resistant support groove 22, the soft body wear-resistant elastic plate 21 is disposed within the soft body wear-resistant elastic support groove 22, and the soft wear-resistant elastic support groove 22 is fixed to the sleeper 1, and the track body 3 is fixed in the soft wear-resistant panel. On the other hand, a multi-group elastic assembly 23 is provided in the soft-resistant elastic support slot 22, and the arrangement of the resilient assembly 23 is provided for the hard-removal connection of the soft wear-resistant elastic plate 21 and the soft wear-resistant elastic support groove 22. The setting of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com